Scrubbers

Linear flow scrubber

Next generation scrubber for non-ferrous metallurgy. Compact, efficient and cost saving.

Linear Flow Scrubbers are adjustable and high-efficiency scrubbers that represent a substantial advancement on the already mature technology of the Radial Flow Scrubbers.

Used for dust and particulate removal in saturated waste gases, Linear Flow Scrubbers offer increased energy savings and efficiency thanks to their high adaptability, adjustability capacity to steadily scrub at fluctuating gas flow rates.

Best applied in copper smelting furnaces or converters, zinc smelters and roasters, lead smelters, molybdenum roasters, nickel-copper / platinum smelters and other pyrometallurgical processes.

However, Linear Flow Scrubbers are not to be exclusively used for the non-ferrous metallurgical industry.

Particular features

- Variable adjustment of the scrubbing zone

- External drives for scrubber adjustment

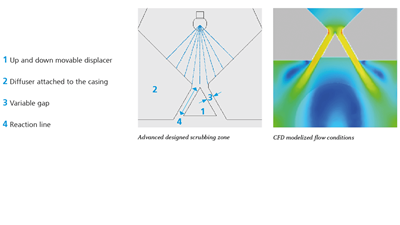

- CFD optimized nozzle arrangement and flow conditions

- Automatic gas pressure drop control

- Steady scrubbing at fluctuating gas flow rates

- Energy saving

- Wide range of volume flow 1:100 at constant pressure drop

- Allows for the accommodation of several scrubbing stages in a single vessel

- Enlarged scrubbing section/reaction line lead to high efficiencies

- High removal efficiencies with low pressure drop

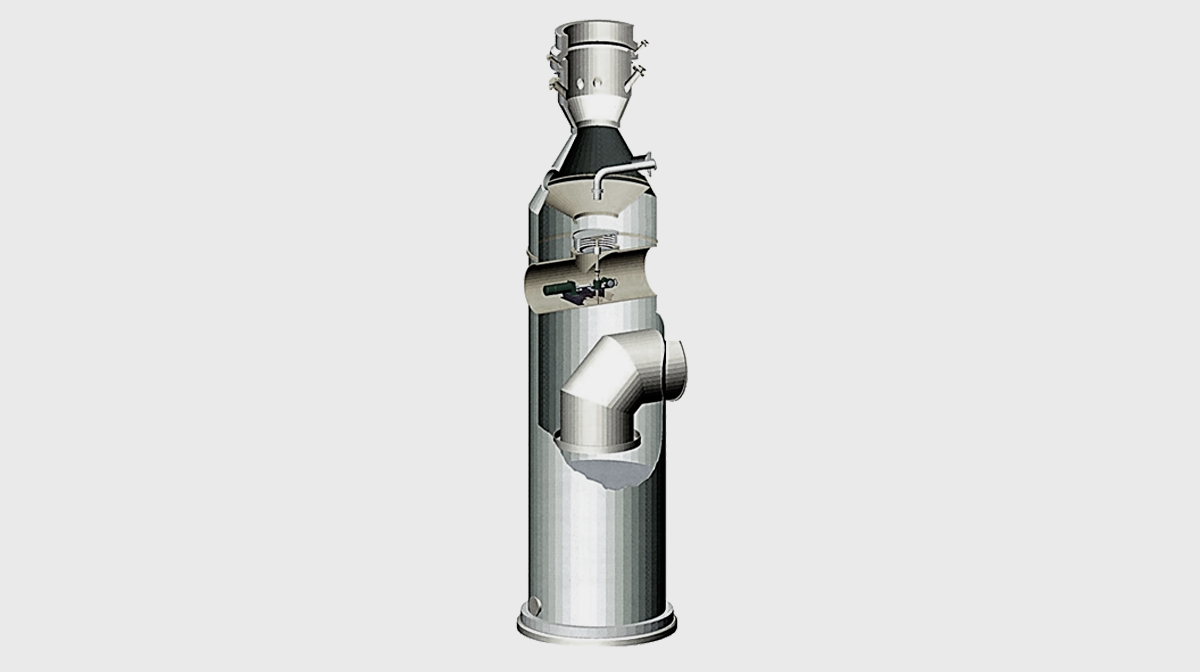

- Compact design, smaller footprint and reduced height

Working Principle

Working Principle of Working Principle

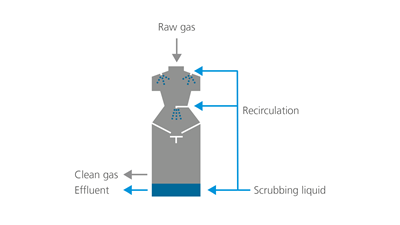

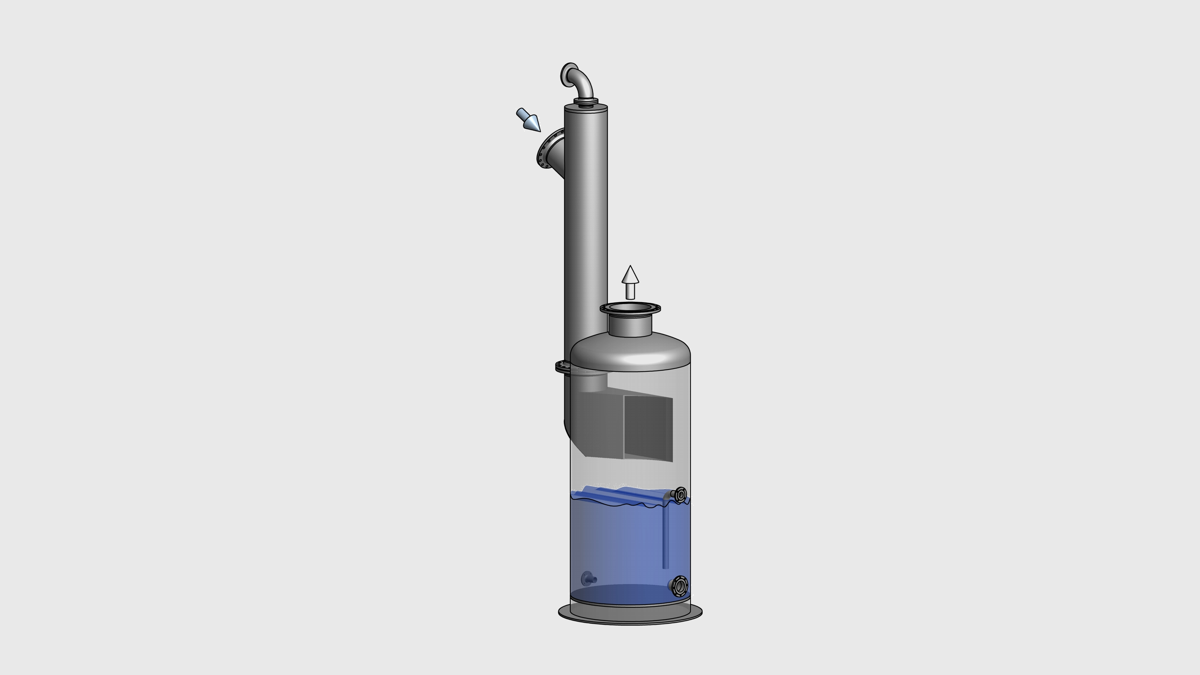

The raw gas enters from the top. The scrubbing liquid is injected though peripherally arranged nozzles upstream the scrubbing zone. The gas and the scrubbing liquid enter from above and pass through the scrubbing zone. The scrubbing zone is characterized by an extended reaction line or gap that is formed by a movable displacer, with tapers towards the top, and a diffuser attached to the casing.

The relative velocity between the gas and the scrubbing liquid, which is decisive for scrubbing efficiency, occurs along the reaction line. By lifting or lowering the displacer the cross-section of the scrubbing zone can be varied, which allows, even with changing gas volumes, to maintain the gas velocity constant in the reaction line and to keep a constant pressure drop across the scrubbing zone. In this way, defined collecting efficiency can be ensured. The differential pressure is the control parameter.

In cases where gases are hot and not saturated, linear flow scrubbers can be combined with an upstream quench stage for raw gas saturation and pre-dedusting.

Downloads

منتجات ذات صلة

جهاز التنقية لتنظيف العوادم من GEA

أدت الحاجة إلى وجود وحدة تتميز بالمرونة قادرة على التغلب على مشكلات الغازات المتسربة من الصناعات المتعددة إلى إنتاج أجهزة تنقية الغاز ذات فجوة حلقية القابلة للتعديل في عام 1950 والتي أصبحت اليوم من بين أكثر أجهزة تنقية الغاز عالية الكفاءة. وبقدر ما يمثل الحجم الحبيبي لجزيئات الغبار الصلبة والسائلة وتركيز المكونات الغازية في خليط الغاز حالات من ال...

أجهزة تنقية الغاز الفنتوري

أنبوب قائم عمودياً مع مخنق فنتوري ومزيح (مخروط فنتوري) وفوهات رش مرتبة بشكل مركزي في الأنبوب فوق المخنق الفنتوري.

أجهزة تنقية الغاز النفاثة

أنبوب قائم عمودياً أو بشكل منحدر مع مدخل غاز عمودي وفوهات دافعة مرتبة بشكل مركزي في الأنبوب فوق مدخل الغاز الجانبي.

Radial flow scrubber

Adjustable flow scrubbers with high collecting efficiencies achievement even when working with critical substances. Mainly used for either gas cooling (to reduce the temperature by water evaporation) or gas cleaning (to condense aerosols and remove solid impurities).

رؤى GEA

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

البيرة الخالية من الكحول: إنهم يريدون كل شيء - إنهم يريدون أقل

كان هناك وقت حيث من النادر استخدام عبارتي "بيرة خالية من الكحول" و "طعمها جيد" معًا في الجملة نفسها، خاصة من قبل المستهلكين. ولكن قطعت البيرة منخفضة الكحول والبيرة الخالية من الكحول شوطًا طويلًا - وأصبح الكثير منها الآن مشروبات منعشة في حد ذاتها - بفضل جزء صغير من تكنولوجيا GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.