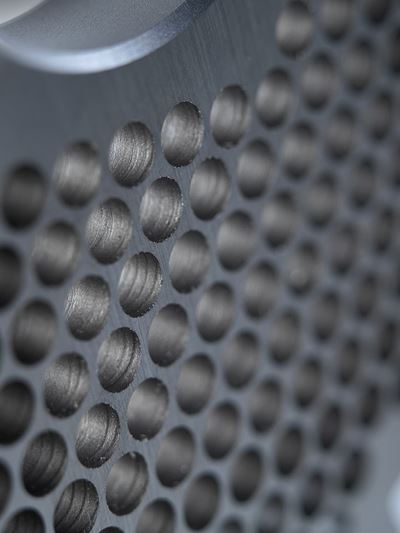

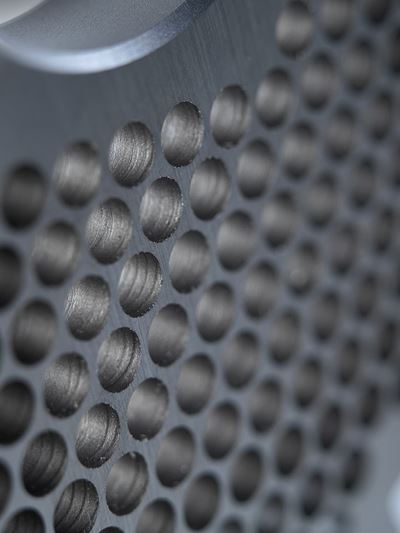

GEA Hole Plates, Knives and Pre-cutters

Clear cut, minimum temperature increase, high productivity and lowest possible wear: GEA spare part and tooling portfolio can safeguard the performance of your grinding and emulsifying equipment day in day out. Our global Service organization and highly experienced team of application specialists can support you with the right choice for your equipment.

Ensuring high cutting performance with original parts for food grinders and emulsifiers

Fresh or frozen meat, vegetables or cheese – no matter what application, hole plates, knives and pre-cutters for industrial food grinding or emulsifying machines work perfectly together. They ensure the highest product quality, improve yield and add value when grinding raw materials for mixes such as premixes for sausage emulsions, the final grinding for hamburgers and pepperoni. The tooling equipment is available for all food grinders in the GEA food grinding family, such as the GEA CombiGrind and GEA PowerGrind. It's also available for all emulsifiers in the GEA emulsifying family, such as GEA EcuCut. Whether you need a single machine or a fully automated preparation line, we have all the ingredients to help you lead in a world of changing tastes.

When spare parts are vital, GEA has them for you

Genuine spare parts from GEA provide you with the level of safety required to improve the efficiency of your plant. GEA customers benefit from a comprehensive and efficient spare parts service:

- Highest safety level

- Long-term availability

- Optimized delivery times

- Maximum service life

- Highest quality standards

- Optimized spare part management

Authentic GEA spare parts protect your investment, keeping you up and running at top efficiency and reliability. Each part is warranted to be manufactured to extremely high standards. Custom pre-analysis of critical machine parts, in time delivery and global availability help to ensure safe plant operation.

Support from GEA experts

Maintain safe and reliable performance of your industrial food grinding and emulsifying machine with the correct pre-cutters, knives, inserts and hole plates. Support is available from GEA's highly skilled food technologists, who can assist in selecting the correct knife setup to match every application. GEA food technologists are available, around the clock and worldwide, to keep you up and running.

Unique GEA FlexGrind System

The FlexGrind system uniquely offers a combination of the spring-loaded knife and the ring around the knife. Its key advantage is that both fresh and frozen meat can be ground without changing cutting parts, worm or lining.

This unique system is also available for the PowerGrind.

GEA Technology Center Bakel

Investitionen absichern!

Ensuring high cutting performance with original parts for food grinders and emulsifiers

Fresh or frozen meat, vegetables or cheese – no matter what application, hole plates, knives and pre-cutters for industrial food grinding or emulsifying machines work perfectly together. They ensure the highest product quality, improve yield and add value when grinding raw materials for mixes such as premixes for sausage emulsions, the final grinding for hamburgers and pepperoni. The tooling equipment is available for all food grinders in the GEA food grinding family, such as the GEA CombiGrind and GEA PowerGrind. It's also available for all emulsifiers in the GEA emulsifying family, such as GEA EcuCut. Whether you need a single machine or a fully automated preparation line, we have all the ingredients to help you lead in a world of changing tastes.

When spare parts are vital, GEA has them for you

Genuine spare parts from GEA provide you with the level of safety required to improve the efficiency of your plant. GEA customers benefit from a comprehensive and efficient spare parts service:

- Highest safety level

- Long-term availability

- Optimized delivery times

- Maximum service life

- Highest quality standards

- Optimized spare part management

Authentic GEA spare parts protect your investment, keeping you up and running at top efficiency and reliability. Each part is warranted to be manufactured to extremely high standards. Custom pre-analysis of critical machine parts, in time delivery and global availability help to ensure safe plant operation.

Support from GEA experts

Maintain safe and reliable performance of your industrial food grinding and emulsifying machine with the correct pre-cutters, knives, inserts and hole plates. Support is available from GEA's highly skilled food technologists, who can assist in selecting the correct knife setup to match every application. GEA food technologists are available, around the clock and worldwide, to keep you up and running.

Unique GEA FlexGrind System

The FlexGrind system uniquely offers a combination of the spring-loaded knife and the ring around the knife. Its key advantage is that both fresh and frozen meat can be ground without changing cutting parts, worm or lining.

This unique system is also available for the PowerGrind.

GEA Technology Center Bakel

Investitionen absichern!

Downloads

Verwandte Produkte

GEA CombiGrind I

The GEA CombiGrind I has been designed as a single, compact unit that combines an intermeshing paddle mixer and a high-performance grinder. The unit is ideal for mixing and grinding pre-ground meat and fragile meat products, especially when fast, effective mixing, perfect granulometry and high contrast color definition are essential.

GEA PowerGrind

Lebensmittelzerkleinerung, die alle Erwartungen übertrifft

Service-Produkte

GEA FormPlates

Get the best out of your GEA food forming equipment with original forming plates. Choose from an extensive range of food forming plates for meat, poultry, fish, meat-replacement, vegetables and cheese. The GEA FormPlates are suitable for all formers in the GEA food forming family, such as the GEA MultiFormer and GEA FreshFormer.

GEA Knockout E-series

Producing the best quality formed food products has become even easier. Whether you use a GEA MultiFormer, GEA FreshFormer or any other GEA plate forming equipment, now you can optimize your forming technology in only a few minutes and boost your performance. With the GEA Knockout E-series, formed products are released smoothly and easily using a...

GEA InsightPartner for food processing and packaging equipment

By providing instant access to real-time equipment data, InsightPartner helps food processors manage their production better. Our cloud-based solution provides advanced analytics and comprehensive insights based on continuous data monitoring.

GEA RemotePartner for food processing and packaging equipment

GEA RemotePartner combines digital machine access and remote support to help you swiftly identify the root cause of any equipment issue and get instant assistance from GEA experts. The result: faster issue diagnostics and resolution, enhanced machine performance, greater efficiency and minimal downtime.

GEA Insights

Gefriertrocknung in der Pharma-Branche: Alle Vials sind gleich! Oder?

Nur eine Zeiterscheinung oder die Zukunft? In jedem Fall wird die hundertprozentige Nachverfolgbarkeit von Vials für pharmazeutische Unternehmen, die Gefriertrocknung einsetzen, ein zunehmend wichtiges Thema. Wir bei GEA verfolgen diese Entwicklung aufmerksam und prüfen mögliche Lösungen. Vor allem aber verfügen wir über die Erfahrung, den Sachverstand und das Know-how, sie umzusetzen.

Es geht auch ohne: Alkoholfreies Bier kommt an

Es gab Zeiten, in denen die Worte „alkoholfreies Bier“ und „schmeckt gut“ kaum je im selben Atemzug genannt wurden – schon gar nicht von den Konsumenten. Doch alkoholarme und alkoholfreie Biere haben eine enorme Entwicklung hingelegt und sind heute vielfach als Erfrischungsgetränke etabliert. Nicht zuletzt dank der Technologie von GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.