Partner for a secure industrial control system

GEA Codex® Asset Care

Safeguard your industrial control system (ICS) and generate security awareness with GEA Codex® Asset Care.

The convergence of information and operation technology (IT/OT) is creating a new world that is open to myriad opportunities and challenges. As production facilities become more interconnected, they also become more vulnerable to cyberattacks and other risks. In this increasingly digitalized environment, a brighter spotlight is now being shone on complex — and potentially susceptible — industrial control systems.

Give your ICS the best protection

Keeping up with digital transformation and safeguarding your system infrastructure is important. GEA can support you with a solution that will show where your industrial control system needs protection and what action you should consider taking. It is framed in the international standard IEC-62443 on the security of Industrial Automation and Control Systems.

Key benefits:

- Get automation expertise with audits performed by GEA specialists who are familiar with your control system.

- Improve the security and control of your assets, patches, risk analysis and data integrity.

- Minimize cost-efficiency losses owing to unscheduled plant shutdowns.

- Reduce investment costs and keep your ICS constantly updated.

- Securely store and centralize all your asset information in a digital tool.

Maximize operational efficiency

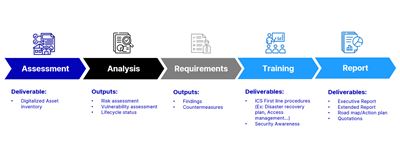

This solution is a deep dive analysis consisting of five phases that are repeated annually to maintain the integrity of your ICS.

What GEA Codex® Asset Care offers

- Full visibility of OT network levels based on Purdue’s models in a digital tool.

- Revision of procedures related to the Industrial Control System (ICS).

- Obsolescence status.

- Automatic communication of vulnerabilities published by the vendors.

- Analysis of possible OT asset threats and vulnerabilities.

- Vulnerability based risk calculation.

- Mitigation plans, countermeasures, roadmap, and costs to address identified risks.

- Executive and technical reports of the digital service.

- Security awareness for specific roles involved with the Industrial Control System; your people are the first point of defense.

Downloads

Related Products

GEA Codex® Remote Support

With GEA Codex® Remote Support, you can contact GEA automation engineers to solve any unforeseen situation related to a plant’s control system and resume production quickly.

GEA Codex® Academy

GEA Codex® Academy is the knowledge-sharing platform for Codex, our scalable automation solution that’s based on the most frequently used systems in the industry (Siemens, Rockwell, AVEVA and Ignition).

GEA Codex®

GEA Codex® is a scalable automation solution that can be applied to a wide range of industries. This software not only ensures safe operation, high product quality, improved performance, data management and value extraction, it also provides global service support for your control system.

GEA Codex® Service solutions

GEA Codex® Service solutions are designed to optimize your plant’s control system, including training, maintenance, support and security, ensuring maximum efficiency and productivity while minimizing downtime and reducing costs.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.