Conventional piping

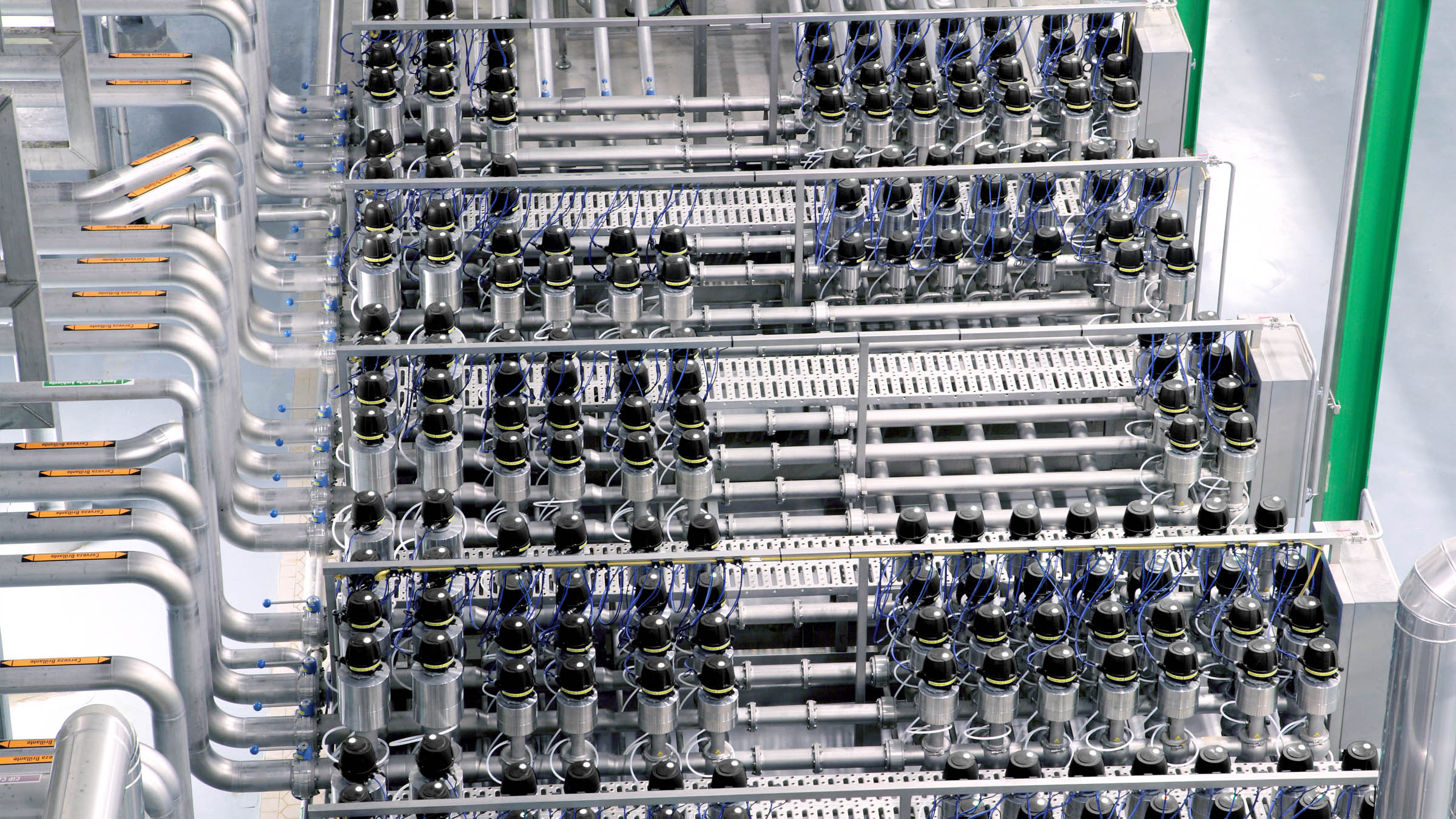

Valve blocks, pipe fences, and panels are used in fermentation and maturation areas. The piping systems are assigned to specific tank lines and supply them with media.

Factory prefabricated valve blocks, panels, and pipe fences ensure the distribution and regulation of gases and liquids within the production process.

Downloads

Related Products

Pipe Fences Piping Solutions

Pipe fences of GEA provide a cost-effective solution for media distribution in breweries. Just like the swing bend panels, our pipe fences are designed to customer specifications and individually tailored for your system.

GEA ECO-MATRIX® Piping Solution

The fully automatic pipe connection system is based on a compact tank outlet tree. The short vertical pipe below the tank in combination with the ECO-MATRIX® double-seat valves guarantees good cleaning conditions and minimum product losses.

Valve Blocks Piping Solution

Our extensive experience and expertise in valve block design guarantees high maintainability/accessibility as well as low space requirement.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.