Ring Dryers

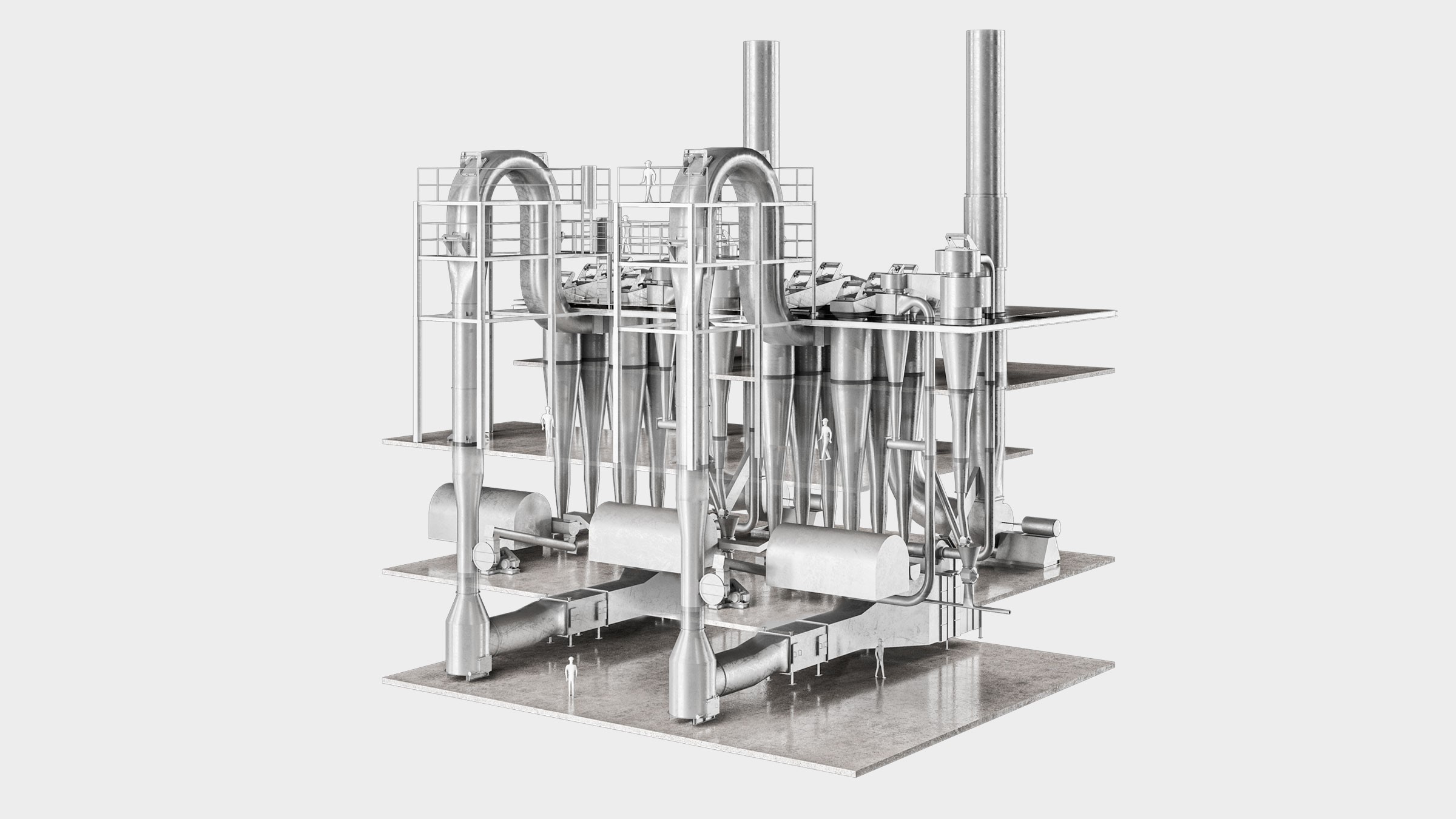

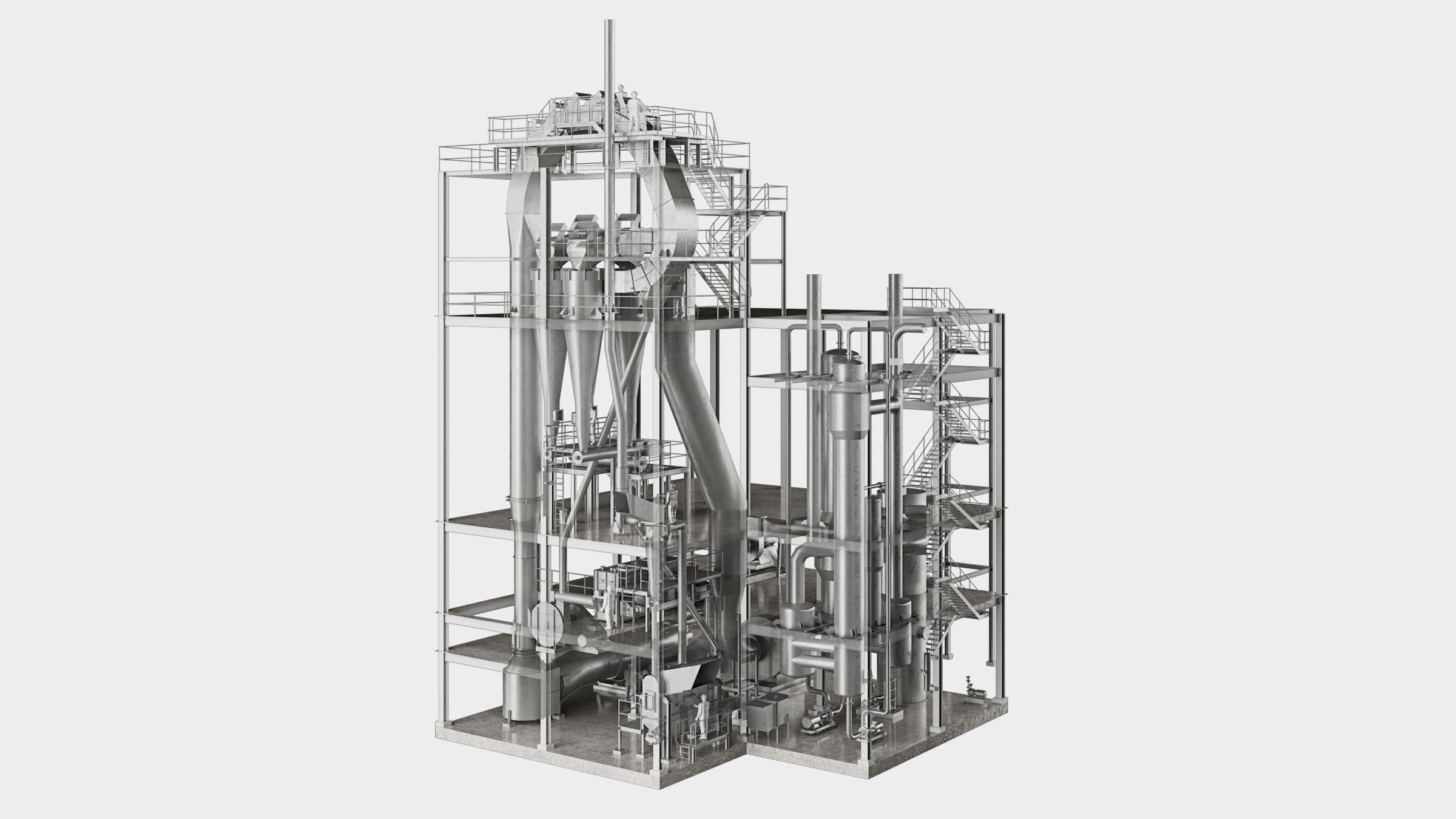

Ring Dryer

Provides control of residence time and particle size; resulting in efficient and even drying.

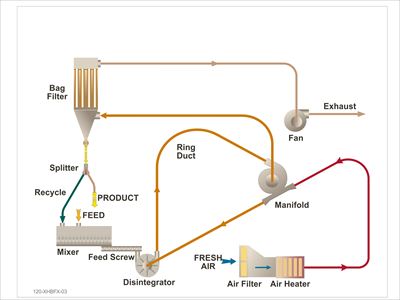

The Ring Drying Process

The manifold uses the centrifugal forces created through passing a product containing airstream around a curve to concentrate the product into a moving layer. The adjustable splitter blades are used to cut this layer and return the heavier, semi-dried material back to the hot air stream at the inlet of the dryer for another pass through the system while the lighter, drier product exits the manifold and proceeds to the product collection system. Manifolds can have single or multi classification blades and are often used in combination with disintegrators for greater control of particle size, product moisture and exhaust temperature.

This selective extension of residence time enables the Ring Dryer to process many materials which were traditionally regarded as difficult to dry in a Flash Dryer. Depending on the specific application, GEA offers custom designed systems based on proven configurations and technology to provide flexibility in design and optimal performance.

The Ring Dryer has been used to dry products in many industries including food, chemical, mineral and plastics. A broad range of feed materials including powders, cakes, granules, flakes, pastes, gels, and slurries can be processed. For slurries, pastes, or sticky materials, our specifically designed feed system allows back-mixing of the wet feed with a portion of dry product to produce a suitable conditioned material for feeding into the dryer. Special extrusion systems are also used for viscous products such as vital wheat gluten.

Features

- Multi or single stage classifier

- Choice of various disintegrators and dispersers

- Choice of a buffer hopper or back-mixing system if required

- Product recirculates to hottest air

- Feed introduced at reduced inlet temperature

- Can be designed for open circuit or partial gas recycle

- Can be designed for operation in an inert atmosphere

Benefits

- Uses centrifugal forces to provide extended residence time for the heavier wetter particles while allowing the lighter dryer particles to be transferred to product collection

- Use of the disintegrator/disperser in combination with the manifold provides close control of particle size, product moisture and exhaust temperature to ensure the best product quality

- Flexibility to work with different dewatering systems and to enable use with friable and non-friable wet feeds

- Provides the highest driving force to minimize required airflow and resulting dryer size and fan power.

- Reduces risk of thermally damaging product quality

- Enables energy savings and system integration

- Suitable for operation with solvent and recovery thereof.

Process Flow Diagram

Downloads

Related Products

Flash Dryer

The GEA Flash Dryer is a pneumatic system primarily used to dry products requiring the removal of free moisture. Drying takes place in a matter of seconds.

Feed-Type Ring Dryer

The Feed-Type Ring Dryer incorporates a top bend and simplified manifold, with the heavier material recycled via a chute into the wet feed disperser. The Feed-Type Ring Dryer is used for waste products, sludges, animal feeds, organic fertilizers and chemicals.

SWIRL FLUIDIZER®

Dry pastes, filter cakes and viscous slurries more cost-effectively with the SWIRL FLUIDIZER®

P-Type Ring Dryer

In addition to improving the thermal efficiency of the system, the use of the P-Type manifold in recycling the solids to a cooler section of the system, also minimizes the risk of thermal degradation. As a result the P-Type Ring Dryer is well suited to use with thermally sensitive materials including modified starches and soy fibre.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.