The workhorse of industry.

Rotary Dryers

The GEA Rotary Dryer is extensively used throughout the process industries and is highly reliable under the most arduous operating conditions.

Principles of Rotary Drying

The directly heated rotary dryer operates on the principle of lifting and showering the product through a hot gas stream moving.

The efficiency of the dryer is largely dependant on the differential between the inlet and exhaust gas temperatures, although the heat transfer rate is also influenced by the relationship between the design of flights and the speed of rotation. However, irrespective of the gas and material temperatures the drying (or residence) time may be critical, as this is governed by the rate of diffusion of water from the core to the surface of the material.

For greater thermal efficiency and where inertization is required, recycling of exhaust gases can be used. This can be implemented on all our airstream drying systems and retrofitted on customer's existing drying operations.

For special applications, the rotary cascade design is adapted to provide a shortfall, or 'Cruciform', lifter configuration.

Features of the Rotary Drying

- Robust construction with various lifter options

- Can be co-current or counter-current

- Permits use of higher drying temperatures

- Relatively long residence time

- Drum provides dispersion as material is conveyed along the length

- Can be designed for open circuit or partial gas recycle

Benefits of Rotary Drying

- Combines flexibility with reliability resulting in a long service life. The rotary is also suitable for operation with a wide range of materials & particle sizes and can more readily accommodate 'upset' up-stream process conditions

- Co-current is suitable for materials with relatively high moistures and provides rapid evaporation without overheating the product.

- Reduces equipment size and the associated capital and operating costs

- Promotes diffusion drying

- Relatively low fan power and low headroom

- Enables energy savings and system integration

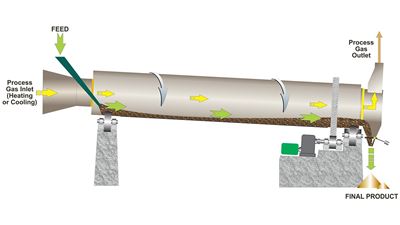

Co-Current Configuration

Co-Current Rotary Dryers are the most widely used and are particularly suitable for drying materials containing a high moisture content, which are heat sensitive or have a tendency to stick or cake.The wet material is in contact with the gas at its highest temperature, which rapidly evaporates surface moisture. The initial heat transfer rate is high, causing an immediate and considerable drop in gas temperature, which prevents overheating of the material and the dryer shell. The final product is in contact with the gas at its lowest temperature, enabling the moisture content to be readily controlled, usually by maintaining the dryer exhaust gas temperature at a pre-set value.Features

- Wet material is in contact with the gas at its highest temperature, which rapidly evaporates surface moisture

- The final product is in contact with the gas at its lowest temperature

Benefits

- Initial heat transfer rate is high, causing an immediate and considerable drop in gas temperature, which prevents overheating of the material and the dryer shell; co-current dryers are particularly suitable for drying materials containing a high moisture content

- Enables the moisture content to be readily controlled

Process Flow Diagram

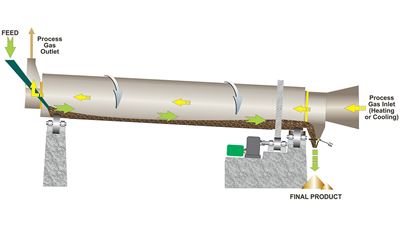

Counter-Current Configuration

Counter-Current Rotary Dryers are more suitable for materials that must be dried to very low levels of moisture, where the last traces of moisture are difficult to remove, or where an elevated product temperature is desirable.They are also used effectively as combined dryer / preheaters. However, since the final product is in contact with the gas at its highest temperature the counter-current dryer is often unsuitable for heat sensitive materials. Although this system can be more efficient, moisture which is to remain in the product, is not so readily controlled.Features

- Dry product is in contact with the gas at its highest temperature

- The final product is in contact with the gas at its lowest temperature

Benefits

- Suitable for materials that must be dried to very low levels of moisture, where the last traces are of moisture are difficult to remove, or where an elevated product temperature is desired. Often used as a combined dryer/preheater.

- Enables the moisture content to be readily controlled

Process Flow Diagram

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.