HYGiPac R

HYGiPac R1 – Compact Bag Filler

Limited intervention hygienic powder filling system for low throughputs up to 3 metric tonnes/hr

Limited intervention filling for low capacity powder plants

The GEA HYGiPac R1 limited intervention filling system delivers all of the benefits of our larger capacity Li systems at a reduced filling rate and with a much reduced footprint. This results in improved space utilization, reduced overhead on HVAC and utilities and lower overall operating cost.

Product safety is important to our customers - even at low production volumes. The fully enclosed design and automatic bag handling, filling and closing are essential to prevent product contamination whilst ensuring the safety of the machine operator.

The fully enclosed stainless steel design is durable and low maintenance and this means that the system is inherently reliable and safe – for both the product and the operator. The HYGiPac R1 has been designed to provide total control of the bag at all stages in the filling operation. This ensures peace of mind to the plant owner whilst reducing risk and increasing overall operating efficiency.

How it works

Bags are loaded in stacks onto the infeed conveyor where they are automatically fed into the filling area. The bag is presented to the filling system which takes over and fills to the final weight using our bottom up filling technology. Once final weight is reached, the bag is automatically passed to the closing system where the surplus air is removed and the top seal is closed before passing to the downline and palletising system.

Key Features include:

- Reduced space requirement

- Bag Control - Bag top positively held during entire filling and closing process;

- Operator Exclusion - Controlling the bag eliminates the need for an operator to touch unfilled bags, therefore risk of product contamination is greatly reduced;

- Single machine with integrated functionality from powder in-feed to sealed bag output;

- Enclosed filling area - fully enclosed to prevent dust migration, while ensuring product and operator safety

- Modified atmosphere capable

- Automated machine adjustment via recipe system to suit specific product types and bag sizes;

- Bag De-couple system – transfer of the bag to the heat sealer, eliminating the need for bag top leveling;

- Provision for Automatic Bag De-palletizing System.

Downloads

Related Products

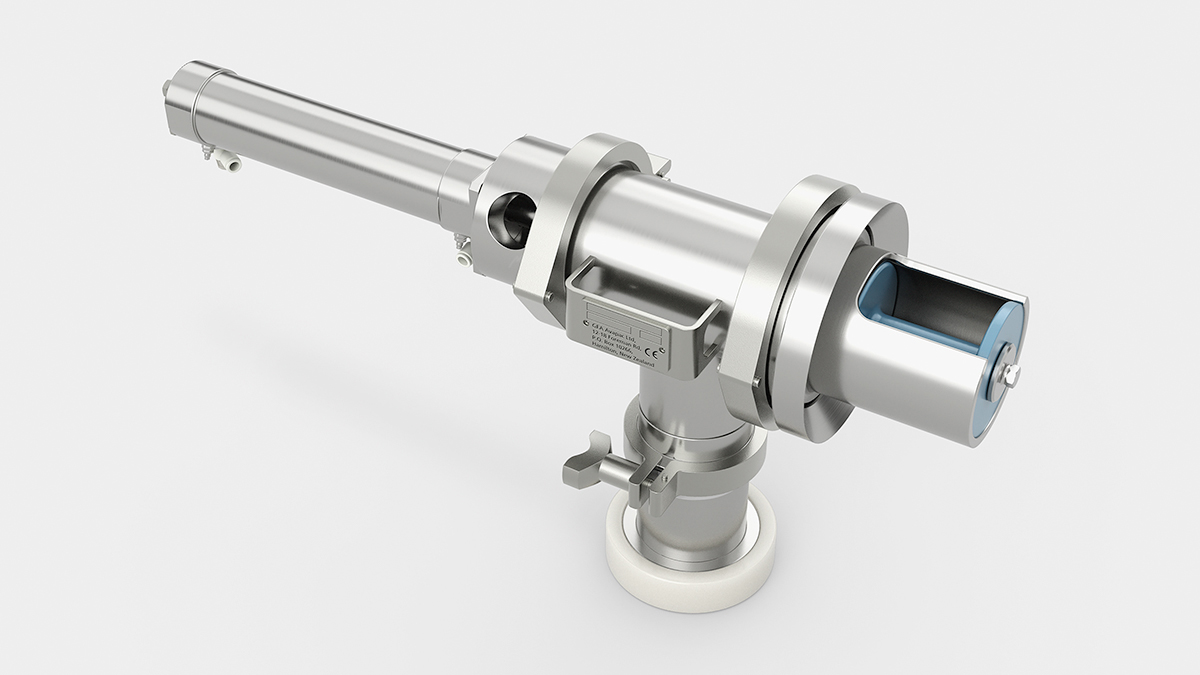

GEA Powder Spool Sampler

null

GEA SmartFil M1 Powder packing system

Semi-automatic powder filling for low production capacity plants. The SmartFil M1 delivers high quality filling of food powders at rates up to 100 bags/hr

Vacuum Powder Sampler

GEA manufactures a range of sampling systems to suit sanitary applications, we use dynamic sampling. Superior methods of powder sampling are obtained by using procedures where the sample is removed from a moving powder bulk.

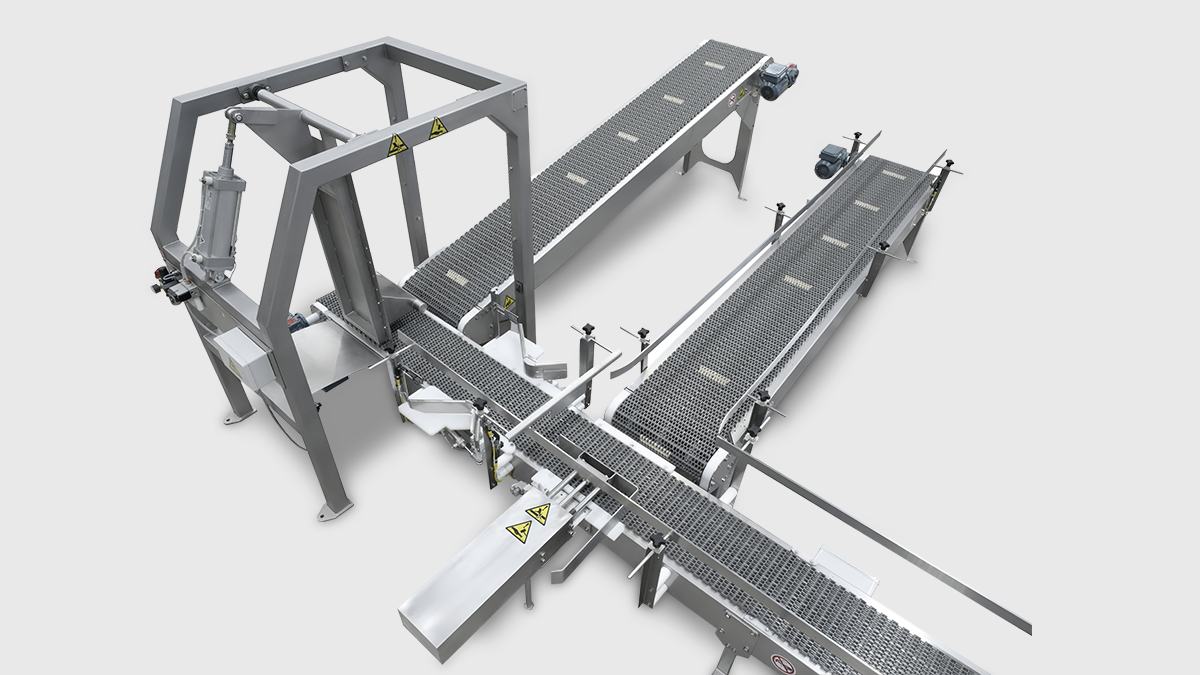

Bag, Box, Drum and Container Handling

GEA container handling includes equipment solutions to meet the varied needs of powder packing plants. These components are selected to provide a complete processing line for filled bags through to the finished product store.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.