GEA SERVICE ‒ CONSTANTLY IMPROVING

GEA Static Pressure Control System

No more frost - a simple upgrade to enhance A-Tec spiral freezer performance

Recognize your benefits

- Less frost build-up at freezer openings

- Fewer defrost cycles resulting in less downtime and greater productivity

- More consistent product profile

- Reduced operator involvement, relieving personnel for other tasks within the plant

- Lower energy usage

- Approximately four-month pay-back time

Avoid frost build-up

All GEA A-Tec spiral freezers, built before 2015, have a manually-operated air balance fan to control internal air flow in line with the changing atmospheric conditions within the production hall. An incorrectly-set fan will increase the risk of frost build-up, more defrost cycles, reduced productivity, an inconsistent product profile and higher costs of production.

With a simple, no-hassle air balance system upgrade

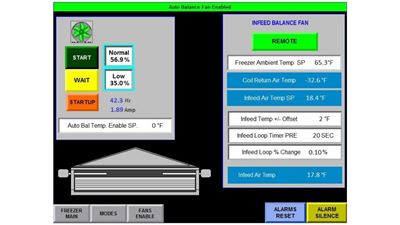

GEA’s new Static Pressure Control System (SPCS) for spiral freezers automatically controls the internal air flow keeping it to a minimum and so dramatically reduces frosting around the air intake. Static Pressure Control System simply upgrades older A-Tec models in line with the latest spiral freezer control technology. Rather than rely on the operator’s judgement, the Static Pressure Control System monitors atmospheric conditions automatically using a PLC algorithm and makes the necessary fine adjustments to the fan speed.

Downloads

Related Products

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.