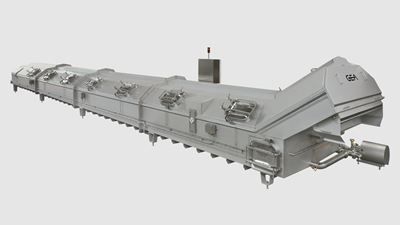

Brining vats

Brining vats are used to add salt to pasta filata cheeses during the final cooling stage.

GEA offers a modular system of brining vats that can be configured on either one or multiple levels and different shapes, to match production rate and plant layout. Additional units can easily be added when extra capacity is needed, or removed if production capacity is reduced.

GEA brining vats are constructed using AISI 316 stainless steel, and offer a modular solution that can be customized according to the cheese type, size of individual product and hourly throughput. The cheeses are transferred into the vat by a conveyor, and are moved through the brine solution to the distal end by means of adjustable water sprayers that are positioned at intervals above the surface of the vats. Product advancement is regulated using an electrical motor-driven cruising system. Products are removed from the end of the vat by means of a motorized belt comprising modular plastic elements. Brining vat set-ups constructed on two levels are configured with a pneumatic lifting system to move the products between levels.

GEA systems are designed for optimum hygiene and easy cleaning. Our brining vats feature pipework and rotary washing turbines for connection to external cleaning-in-place plants. Each system is configured with a centrifugal pump that has the dual roles of recycling the cooling brine water to a plate heat exchanger for recirculation, and also recovering cleaning solutions after a cleaning cycle. Mechanical and electromechanical protection on dangerous areas ensure optimum safety for operators.

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.