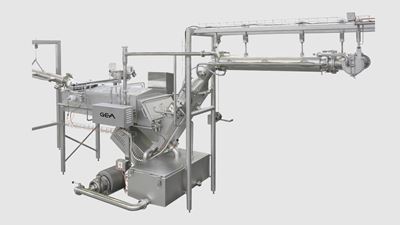

Dry Salt Dosage Systems

GEA can configure dry salt dosage systems with tank capacities of 150-300 kg dry salt. Each unit in our portfolio is designed to be energy efficient, and promise low operating and maintenance costs.

Dry salt dosage systems from GEA are constructed around a double truncated cone-shaped dry salt vat, which is kept in constant rotation to help stop the salt clumping, and is heated via an external jacket.

The tank contains spoons that scoop the salt into a hopper, from where it is transferred to a conveyor pipe. At the end of this pipe a variable-speed auger system transfers the salt to the curd coming out of the stretching machine. The curd cheese is transferred to a Teflon-coated chute in which it is flattened by an adjustable paddle. The cheese is transported along this chute to a rotating drum. A sensor system automatically detects the thickness and speed of the stretched pasta filata as it moves along the chute, and this data is sent to a PLC that adjusts the speed of the salt distribution auger, to ensure that the precise amount of salt is dosed then dosed. The cheese and salt are combined in a rotating drum and transferred to a kneading unit that contains counter-rotating augers. From here the salted pasta filata cheese is transferred to the molding station.

The cheese and salt mixing tunnel can be configured with pipework for connection to a cleaning-in-place (CIP) plant. Whey and cleaning solutions from CIP are collected in a vat that is connected to a centrifugal pump. Servo-motor drives operating the salt distribution and mixing augers guarantee precise, reliable operation.

Offering automated adjustment and fine control, GEA salt dosage systems are accurate to within 0.1% salt dosing. The units are constructed using stainless steel AISI 316 to withstand the corrosive activity of salt.

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.