Specifically designed for goat milking

SR Rapid Exit - Rapid Exit Small Ruminant Parlour

The SR Rapid Exit parlour is available in either a high-line or low-line configuration, making it perfect for those requiring a high-throughput parlour for either sheep or goat milking operations.

One of the quickest milking parlours in terms of animals milked per hour thanks to efficient entry and exit design, the SR Rapid Exit excels at milking small ruminant animals. Animals are quickly and safely guided into the milking parlour, where individual indexing gates align animals to the ideal milking presentation.

Customise your SR Rapid Exit to suit your milking operation – whether you’re looking to build new or retrofit an existing bovine parlour with either a double-up or swing-over milking configuration.

Key features & benefits:

- 20-100 clusters

- Perfect for new builds or retrofit dairy conversions

- Rapid exit gates and a completely open exit area for efficient animal flow and fast exit speeds

- Options for high-line and low-line configurations

- Reduction of labour input and animal stress

- Quick self-loading individual indexing gates

- Individual feed bins and headlocks

- Group feeding as standard

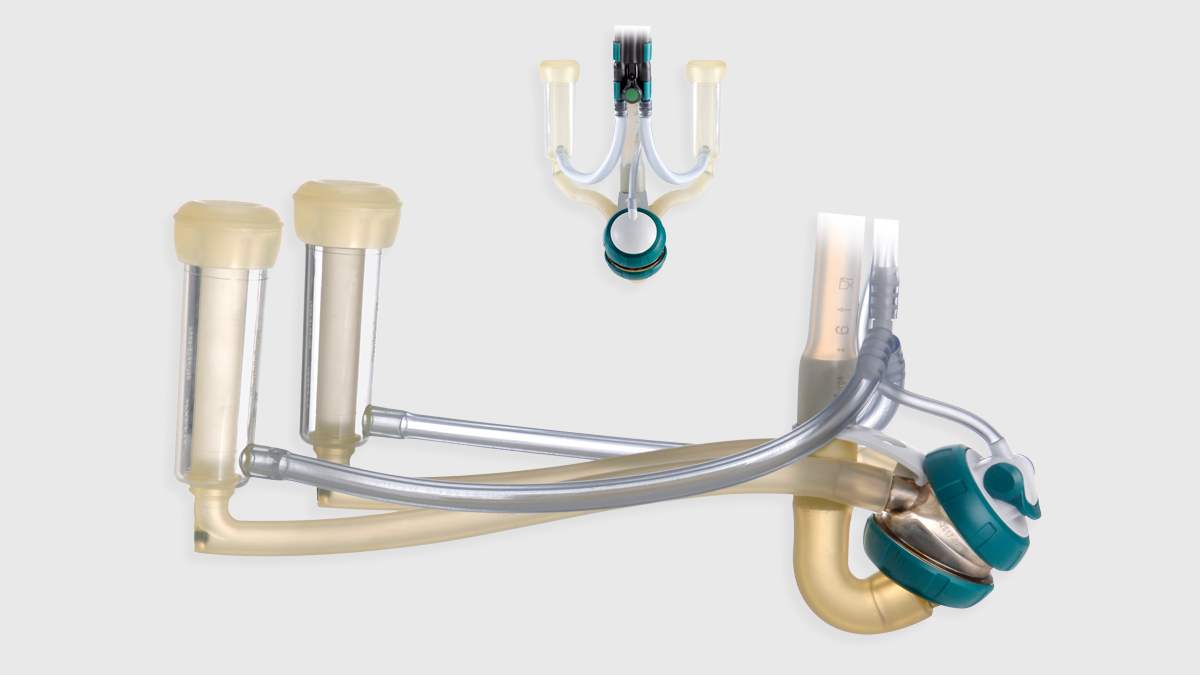

- Clusters without claws for fewer liner slips and efficient milk-out

- Integrated plant control with single-point plant operation

Automation options:

- Automatic cluster removers

- Milk metering

- Herd management software

Milking Performance Goats & Sheep / Hour

| Milking Performance Goats & Sheep / Hour | ||||||

| Rows / Hr | 12 | 10 | 8.6 | 7.5 | 6.7 | |

| Row Times (Mins) | 5 | 6 | 7 | 8 | 9 | |

| No. Goats & Sheep Milked per hour | ||||||

| Size of System | 2 x 20 | 480 | 400 | 343 | 300 | 267 |

| 2 x 30 | 720 | 600 | 514 | 450 | 400 | |

| 2 x 34 | 816 | 680 | 583 | 510 | 453 | |

| 2 x 36 | 864 | 720 | 617 | 540 | 480 | |

| 2 x 40 | 960 | 800 | 754 | 600 | 533 | |

| 2 x 44 | 1056 | 880 | 754 | 660 | 587 | |

| 2 x 50 | 1200 | 1000 | 857 | 750 | 667 | |

Downloads

Related Products

Milking Control Units DeMax & DemaTron

Make the right choice for a better milk production of your dairy farm. The modular GEA milking control technology evaluates your data for precision livestock farming to control your processes.

Milking Cluster TopFlow

The TopFlow milking cluster milks goats and sheep gently and efficiently – even those with difficult teat configurations.

Milking Cluster OviTwin & CapriTwin

CapriTwin milking cluster for goats and OviTwin for sheep: gentle and efficient milking in systems with high-level lines.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.