GEA XPress™ Fiber Separation System

Reliable and efficient fiber separation system to get the most out of manure

GEA XPress™ working principle

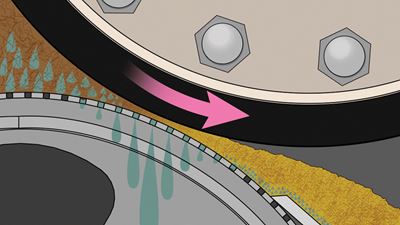

The XPressTM rotation pulls in a steady stream of material from the integrated regulator tank or dewatered material from a slope screen orvertical dewaterer. The fiber material is squeezed between an upper rubber roller and a lower stainless steel screen to remove moisture. The extracted liquid is diverted from the fiber material via openings in the screen roller. The process is repeated two or three times depending on the capacity or dry matter rate targeted.

XPress™ Main Features:

- The GEA XPress™ is constructed with grade 304 stainless steel – the frame, roller shield, motor table, roller arms and accessories.

- The rubber roller is made of small individual sections bolted together to provide easy rotation and replacement of the roller sections, when needed.

- Pressure is applied to the fiber with an air bag system built to handle the conditions in separation rooms. This system provides uniform material compression across the roll.

- Each steel roller and transition chute has an integrated rinsing system.

- Laser level sensor providing accurate readings of the level of solids in the chute between each roller press system.

- Control panel with optional Variable Speed Drive (VSD).

- Each set of rollers uses only 1.5 HP (1.1 Kw).

The GEA XPressTM can be configured according to the size of the herd and desired dry matter rate of the solid outcome. The step-down concept allows increased pressure at each step for optimal moisture removal. It can be configured with an integrated regulator tank or a vertical dewaterer together with a standaloneliquid level regulator tank. The unit also allows an on-site configurable drive with left- or right-hand choices.

"The XPress requires minimal energy input and only basic maintenance for many years of trouble-free performance."

Downloads

Related Products

GEA SlopeScreen™

The GEA SlopeScreen™ is the key component to effective manure separation. Independently managing the solids and liquids gives you the flexibility to determine the most efficient way to use them.

Vertical Dewaterer

The Vertical Dewaterer is used as a dewatering treatment prior to the roller press and can also be used as a stand-alone piece of equipment to thicken material for digestion or further treatment.

Electromix System - Single Piston Pump

A reliable and versatile system designed to homogenize solid dairy manure and liquid into slurry that can be evacuated through small PVC pipe.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.