The high perfomer

GEA Grasso SP2

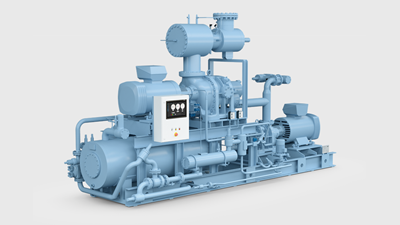

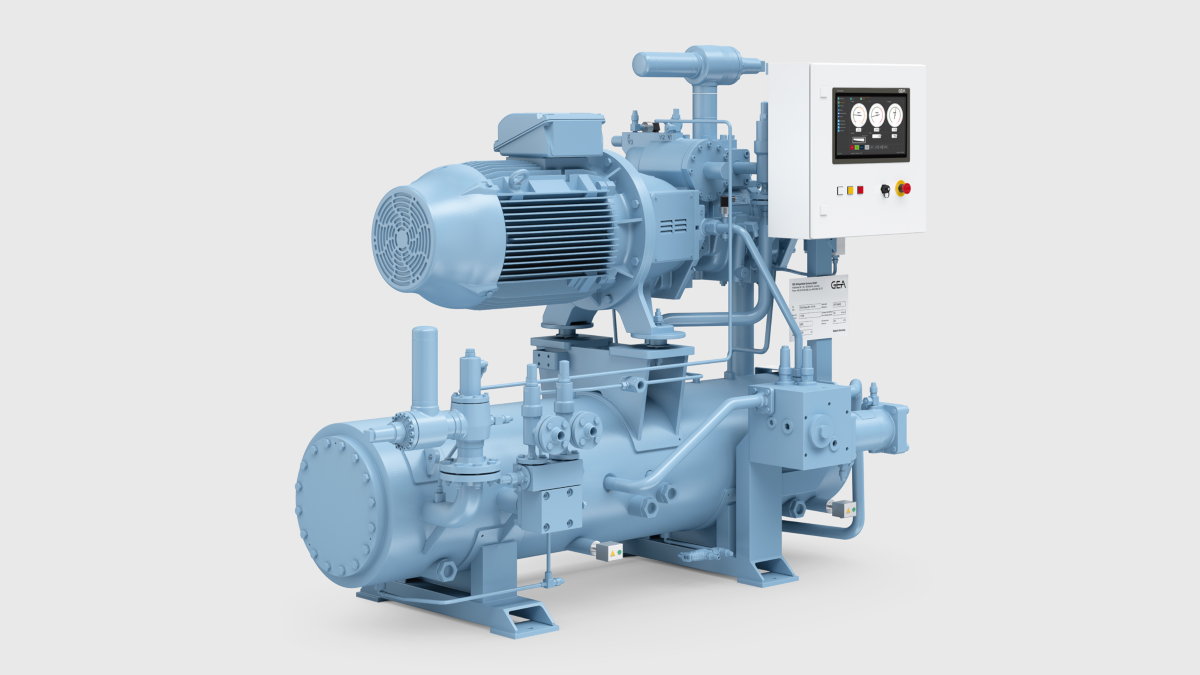

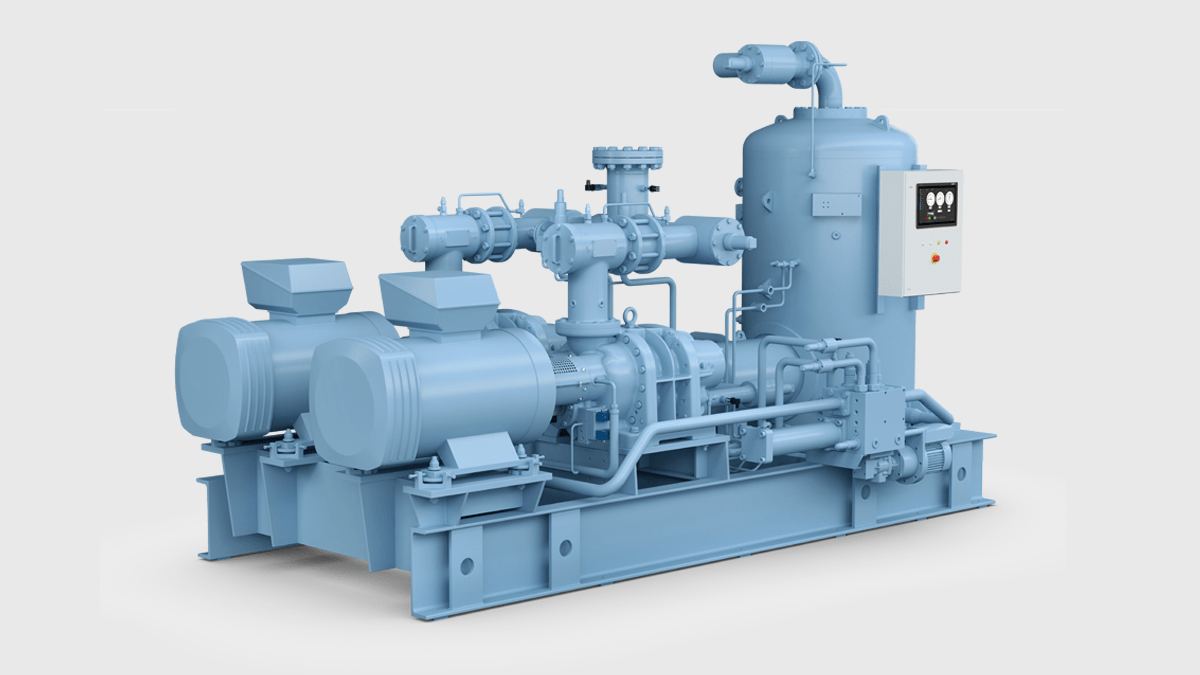

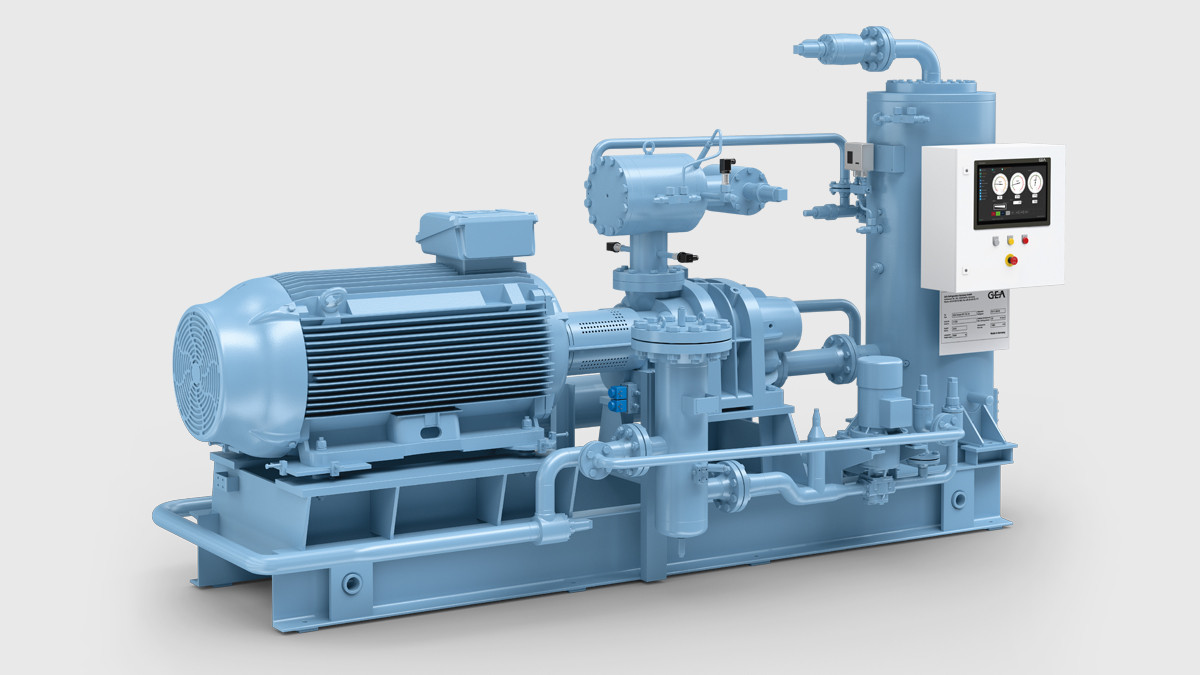

The high performer - GEA two-stage screw packages.

GEA Grasso SP2

A GEA Grasso SP2 package is the efficient and flexible solution for high differential pressure operation. At the same time, the package – based on a common base frame, oil circuit and common control – is easier to install, operate and maintain, and it requires less space than two separate single-stage packages. Thanks to GEA’s state-of-the-art engineering even less than common compound solutions.

The unique design featuring two separate drivelines also offers significant redundancy and flexibility advantages over compound solutions. Individual speed regulation of the two drivelines ensures maximum efficiency also in varying operating conditions and load requirements. Additional flexibility and availability are provided by the possibility to switch off the low-pressure compression stage, for example when servicing the booster compressor or in case low-temperature refrigeration is temporarily not required but only A/C cooling which can supplied by the high-pressure compression stage.

The series includes 18 models (booster screw compressors, each available with several different high-pressure compressor combinations) covering a wide range of 118 to 2,100 kW refrigeration capacity (R717 | -40/+35°C | 3,600 rpm).

Highlights & Technical Features

- Two-stage screw packages optimized for low temperatures and high differential pressure operations

- Flexible operation of low-stage and high-stage compressors

- Intercooler open or closed flash (optional) with additional, individual side load possible

- One piece – easy installation, operation and maintenance, minimized footprint (even less than common compound solutions)

- Variable speed drive motors (optional) with speed range 1,500 - 4,500 rpm (V to XF models 1,500 - 3,600 rpm)

- Stepless capacity control via frequency inverter and/or slide system

- GEA Omni control panel with high-definition 15.6" touch screen

Learn more with GEA RTSelect – our product selection and configuration tool.

| Screw package model | Speed (rpm) | Cooling capacity (kW)* | |

| R717,

-40/+35 °C | R290,

-50/+35 °C | ||

| GEA Grasso SP2 – H | 3600

4500 | 118

148 | 69

87 |

| GEA Grasso SP2 – L | 3600

4500 | 134

170 | 79

99 |

| GEA Grasso SP2 – M | 3600

4500 | 175

221 | 103

130 |

| GEA Grasso SP2 – N | 3600

4500 | 215

271 | 126

159 |

| GEA Grasso SP2 – P | 3600 | 198 | 116 |

| GEA Grasso SP2 – R | 3600

4500 | 252

322 | 149

189 |

| GEA Grasso SP2 – S | 3600

4500 | 319

399 | 188

235 |

| GEA Grasso SP2 – T | 3600

4500 | 359

449 | 211

264 |

| GEA Grasso SP2 – V | 3600 | 429 | 256 |

| GEA Grasso SP2 – W | 3600 | 503 | 300 |

| GEA Grasso SP2 – Y | 3600 | 599 | 357 |

| GEA Grasso SP2 – Z | 3600 | 699 | 417 |

| GEA Grasso SP2 – XA | 3600 | 832 | 496 |

| GEA Grasso SP2 – XB | 3600 | 1068 | 651 |

| GEA Grasso SP2 – XC | 3600 | 1226 | 731 |

| GEA Grasso SP2 – XD | 3600 | 1448 | 863 |

| GEA Grasso SP2 – XE | 3600 | 1786 | 1065 |

| GEA Grasso SP2 – XF | 3600 | 2125 | 1267 |

* With open flash intercooler

Downloads

Related Products

GEA Grasso M packages

Total Cost of Ownership redefinied - Your top choice for cost effectiveness over the entire product lifetime.

GEA Grasso SPduo

Best efficiency with all loads - GEA screw packages with two parallel-mounted compressors.

GEA FES GLX series

The GEA FES XSeries compressor package.

GEA Grasso SP1 HP

CO₂ cooling or NH₃ heating applications - GEA single-stage high pressure packages are the perfect fit for either of them.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.