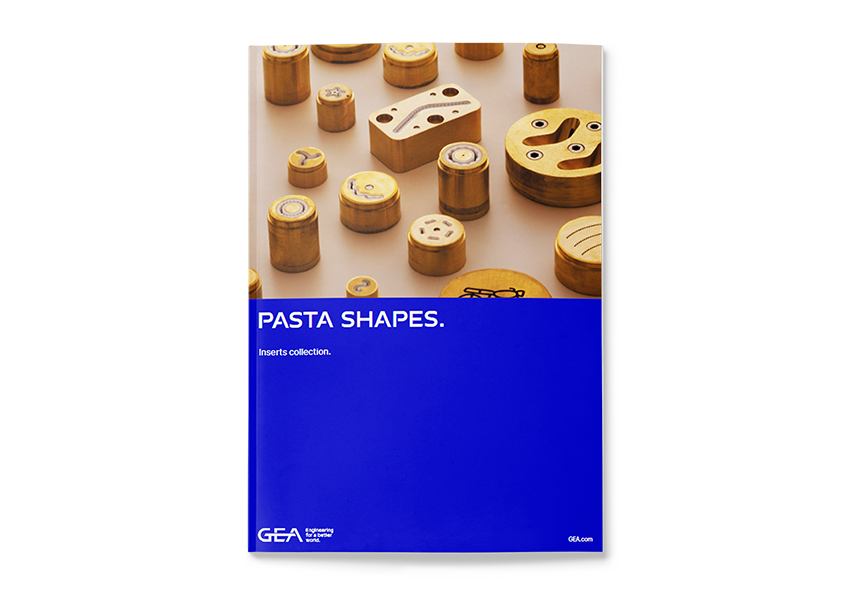

Dies and Moulds Inserts

With more than 800 pasta formats, GEA can produce dies and moulds that can satisfy even the most demanding market requests. From the classic penne, conchiglie, spaghetti, lasagne to the more complex ones that feature shapes of animals or cartoon characters.

Shaping, Coloring and Appealing

Inserts play a big role in product shaping but also in the coloring and general appeal of the pasta at the end of the process. In fact, pasta made with teflon inserts has a glossy appearance and a bright colour, whereas the use of bronze inserts gives the product a greater porosity and a lighter shade.

The inserts provided by GEA cover the following pasta formats:

- Long-cut: spaghetti, vermicelli, bucatini etc.

- Lasagne: lisce, ondulate, ricce etc.

- Nest: tagliatelle, fettuccine, pappardelle etc.

- Short-cut: penne, fusilli, cavatappi etc.

- Soup size: quadretti, routine, tubettini etc.

- Filled short-cut: tufolo, cannellone, lumaca etc.

- Quick cooking and pre-cooked: pennine rigate doppie, cornetti rigati, eliche etc.

- Fancy shapes: inserts to reproduce every shape you can think of.

- Gluten free: a selection of inserts for every category of pasta shape that can be used in the production of gluten free pasta.

Downloads

Download the GEA Pasta Shapes brochure.

Discover the full GEA inserts collection, composed by more than 800 pasta formats, with technical details such as names, sizes and much more.

Related Products

GEA Round Die-Washer

Washing unit which can operate one or two dies. The models designed for pasta dies can feature either an electromechanical control or a PLC one, while the snack and pellet and gluten free models feature only the electromechanical one.

GEA Universal Die-Washer

Washing unit which can operate two dies. According to the model, they can feature either an electromechanical control or a PLC one.

GEA Universal Mini Die-Washer

Washing unit which can operate one die. According to the model, it can feature either electromechanical control or a PLC one. The models designed for pasta dies can feature either one, while the snack and pellet and gluten free models feature only electromechanical control.

Pennaut - Cutter

The Pennaut is designed with the goal of facilitating and speeding up format change operations in short pasta production plants.

Related Videos

Design and manufacturing of inserts and dies

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.