Long-cut pasta - Multidrive production line

GEA new Multidrive technology allows making long cut pasta of unrivalled quality while granting energy savings and reduced overall footprint.

GEA MULTIDRIVE techology: an evolutionary step forward in the manufacture of long pasta that ensures superior quality while keeping an eye on the environment through efficient energy management.

These results are achieved through a number of innovative features allowing improved accuracy on working parameters all over the line, offering best performances in the pre-drying and drying process. The so obtained product is excellent in stability, structural strength and cooking quality.

Continuous innovation is a business driver for many companies; however, only an effective adoption of thorough procedures can turn it into a success factor, thus allowing targets achievement and actual advantage against competitors. This vision brought us to develop cutting-edge technologies that are and will always be GEA trademark.

TAS-MULTIDRIVE

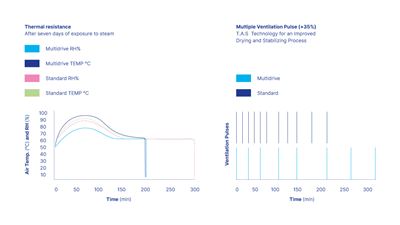

MULTIDRIVE technology is based on a continuous control of thermo hygrometric conditions, by the application of very high gradients of temperature increase and decrease rates, an optimized exhaust air extraction and a Multiple Pulse Ventilation system. The result is an evolution of the well-known GEA Thermo Active System technology (TAS).

Key Features

- Optimized exhaust air extraction and injection

- Accurate control of the temperature and humidity also in the initial stages

- Reduced energy consumption: High-efficiency process: global energy saving up to 30%

- Improved product quality

- Reduced length of the line (-25%)

- Easy access to the dryer

Throughput

- Mono tier: from 1 to 2,5 tons/hour

- 3 tiers: from 1,5 to 6 tons/hour

Downloads

Get the GEA Multidrive brochure.

Revolutionize your dry pasta production process. Learn how our Multidrive technology can take your production process to the next level and how GEA's TAS system has changed the way pasta is dried.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.