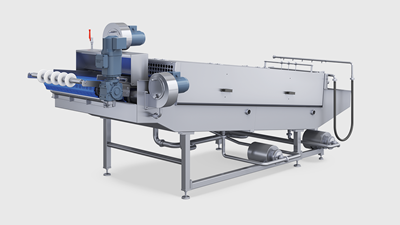

WZ - Washing zone

Machine designed to block the cooking process, cool the product and remove superficial starches.

The WZ is composed of a conveying belt and it features a bottom water tank divided in two parts which allows for the recycling of sprayed water.

On the top it features spraying ramps controlled with a dedicated flow switch and regulating valve. Product is transported by the belt, water is sprayed on the product and then it is gathered and re-sprayed on the charging zone.

From a structural perspective the inclined conveying belt is made with plastic material and controlled through inverter, while the top closing hinged covers can be opened to facilitate internal inspections and cleaning operations. Moreover, the machine is in stainless steel allowing for complete washing.

Thanks to the recycling system the WZ has low water consumption but it retains the ability to cool the product down to 25°C.

Machine performance

- Belt usable width: 750-1200 mm;

- Washing length: 2.5 m.

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.