Pasta Packaging Equipment

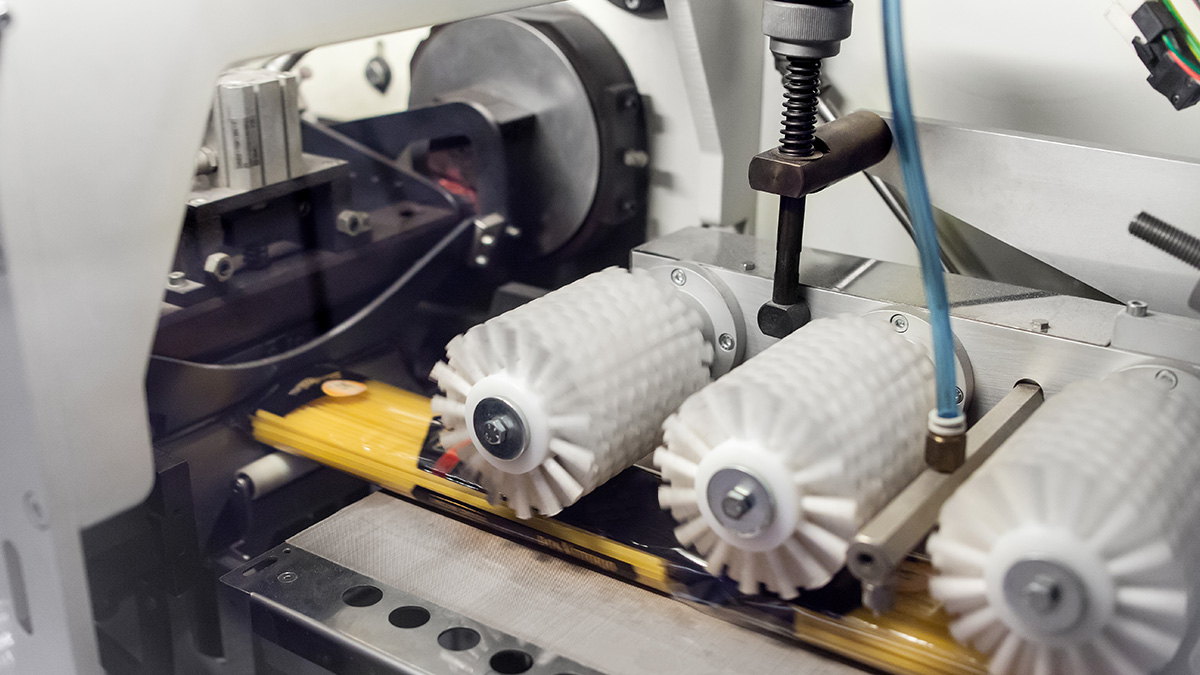

GEA's experience and know-how in the pasta manufacturing sector is resembled in studying packaging solutions aimed at preserving the shape and typical characteristics of pasta, reducing to the minimum the risk of damaging the product.

GEA provides high-speed and efficiency machines designed for long-cut and short-cut pasta, that can be provided also as a packaging unit, paired with weighing systems in order to guarantee every packaging solutions for all kinds of pasta.

Get the GEA Dry Pasta Packaging brochure.

Learn how our Pasta Packaging solutions can help preserve the quality of your dry pasta products and streamline your packaging process.

Products

Showing 4 of 13

GEA H-Packer SI

The GEA H-Packer SI is an intermittent motion packaging machine for long cut pasta and special products in pillow type bags.

GEA H-Packer SO

High speed Packaging system specifically designed for long cut pasta.

GEA H-Packer SO-Plus

A faster, highly reliable and technologically advanced system, comprising a double dosing unit and a continuous motion packaging machine for long-cut pasta packaging.

GEA M-Weigher Series

GEA multihead weighers guarantee the highest performances thanks to their remarkable accuracy and reliability. The highest speed version with 20 hoppers, combined with a continuous motion packaging unit, is able to pack up to 130 bags per minute.

Downloads

GEA and Pastificio Felicetti: an ongoing success story

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.