Storage Silos / Bulk Storage

Powder Silos

GEA specializes in the supply of bulk storage silos and hoppers for food products, including dairy powders, sugar, flour, starch, salt and a wide variety of ingredients, mixtures and cereals.

Features

- Indoor or outdoor silos

- Epoxy coated steel, stainless steel or aluminium construction

- Round silos with conical and chisel

- Vacuum, pressure and explosion relief systems

- Access equipment: ladders, platforms, manholes, windows and illumination

Accessories

- Dehumidification systems for hygroscopic products and humid or tropical environments

- Ventilation systems including heating and cooling as required

- Road tanker filling systems

- Pneumatic and mechanical filling systems

- Loadcell weighing and point, ultrasonic, guided radar etc level measurement

- Discharge equipment using vibratory, aeration and mechanical devices.

Our scope of supply is not limited to the supply of the silo components. We can supply the entire powder storage and conveying system including software and integration to the plant.

Downloads

Related Products

Pressure Conveying - Dense Phase

Dense phase pressure conveying systems use compressed air to push materials from a single or twin pressure pot system through a pipeline to a destination where the air and product are separated.

Vacuum Conveying - Lean Phase

Lean or dilute phase vacuum conveying systems generally use positive displacement exhausters to provide a vacuum (up to 50%) to convey materials through a pipeline to receiving vessel where the air and product are filtered and separated. Lower capacity fan-based systems are also available.

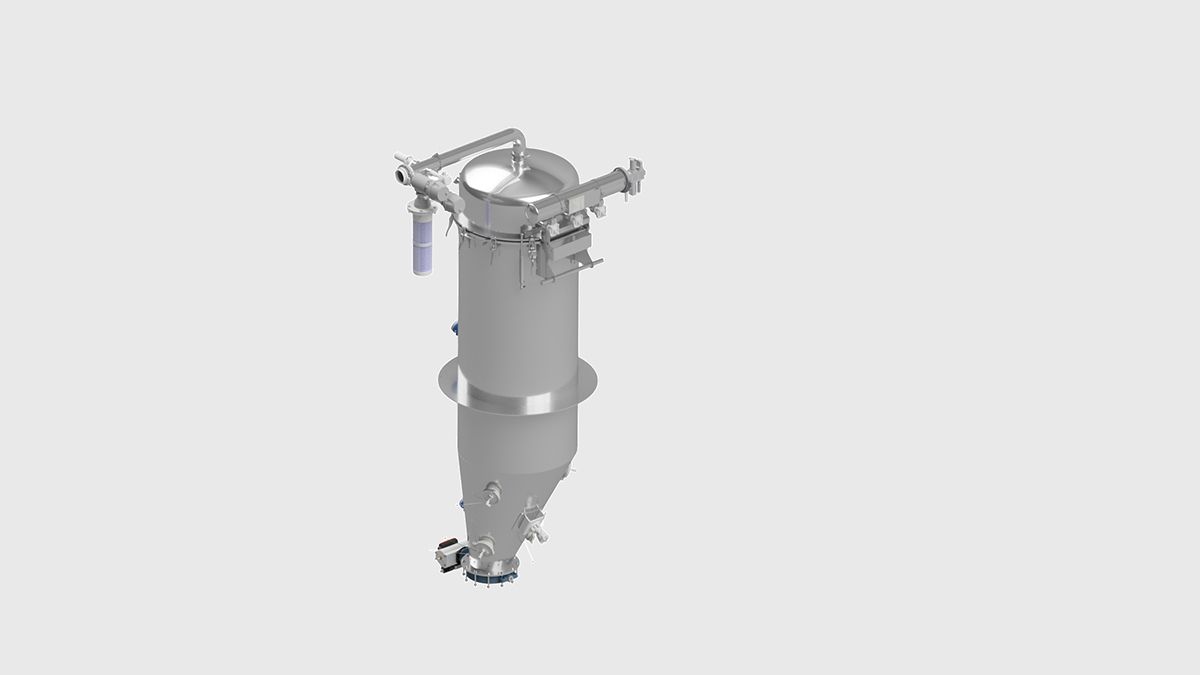

Vacuum Conveying - Dense Phase

Dense phase vacuum conveying systems use high capacity vacuum pumps (up to 99% vacuum) to convey materials from a feed hopper or silo to a receiving vessel or vacuum hopper where the air and product are separated by a filter. When the vessel is full, the vacuum is isolated and the conveyed product is discharged into the destination silo. The prod...

Pressure Conveying - Lean Phase

Lean or dilute phase pressure conveying systems use positive displacement blowers —providing air at up to 0.6 Barg — to convey materials through a pipeline to a destination where the air and product are separated by a filter.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.