Vacuum Technology

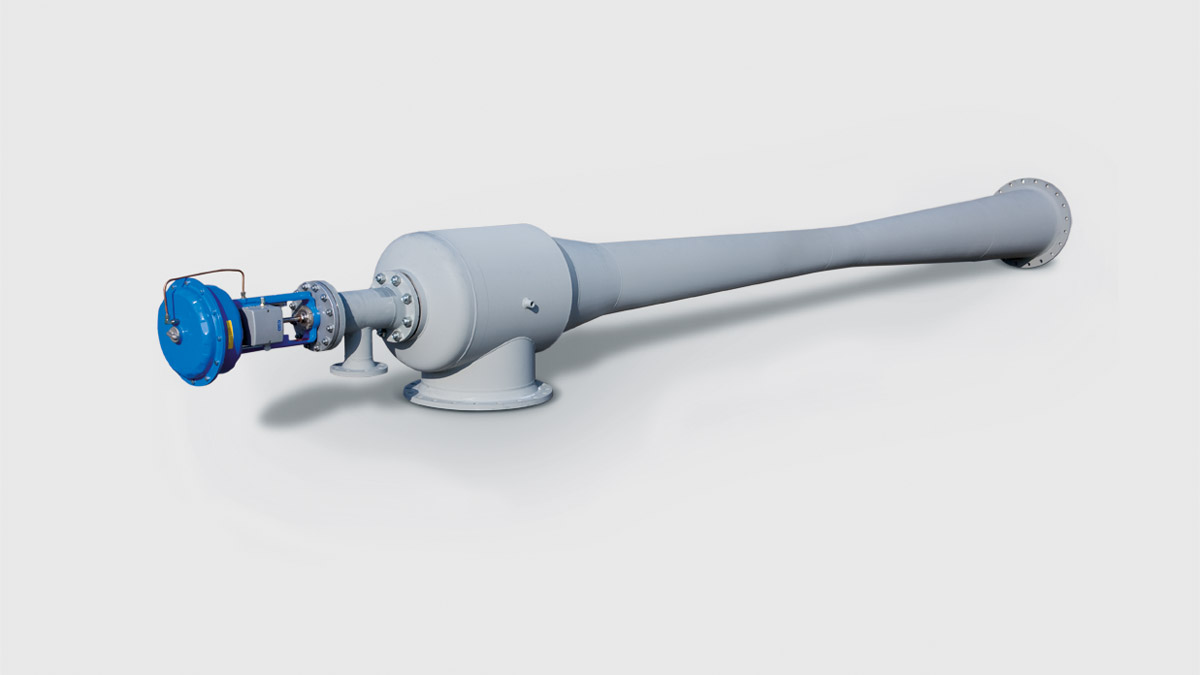

Steam jet ventilator

Steam jet ventilators are based on proven jet pump technology and often used to convey air, gases and vapors.

Applications

Steam jet ventilators are used to:

- To draw of waste air, exhaust gases and vapor

- To ventilate tanks

- As forced blast blowers, or stack ventilators for boiler burners

- To extract and mix exhaust gases from the thermal afterburning

Mode of operation

Steam jet ventilators convey air, gases and vapors against small pressure differences. They operate in a range between ∆p = 0 to 500 mbar. Above 500 mbar, steam jet compressors are used.

The achievable pressure difference between the suction pressure and discharge pressure is the compression of the steam jet ventilator.

Instead of steam, it is also possible to use compressed air or another gas as motive fluid for jet ventilators.

Apart from steam, air or gas, liquids may be used as the motive medium for jet ventilators.

Advantages

- No moving parts

- Maintenance-free

- Can be installed in virtually all situations

- Quickly and easily put into operation

- Almost unlimited life, when a suitable material of construction is chosen

- Can be manufactured from various materials of construction

- Low acquisition costs

As opposed to liquid jet ventilators, steam or gas jet ventilators have the advantage that larger pressure differentials can be managed.

Downloads

Related Products

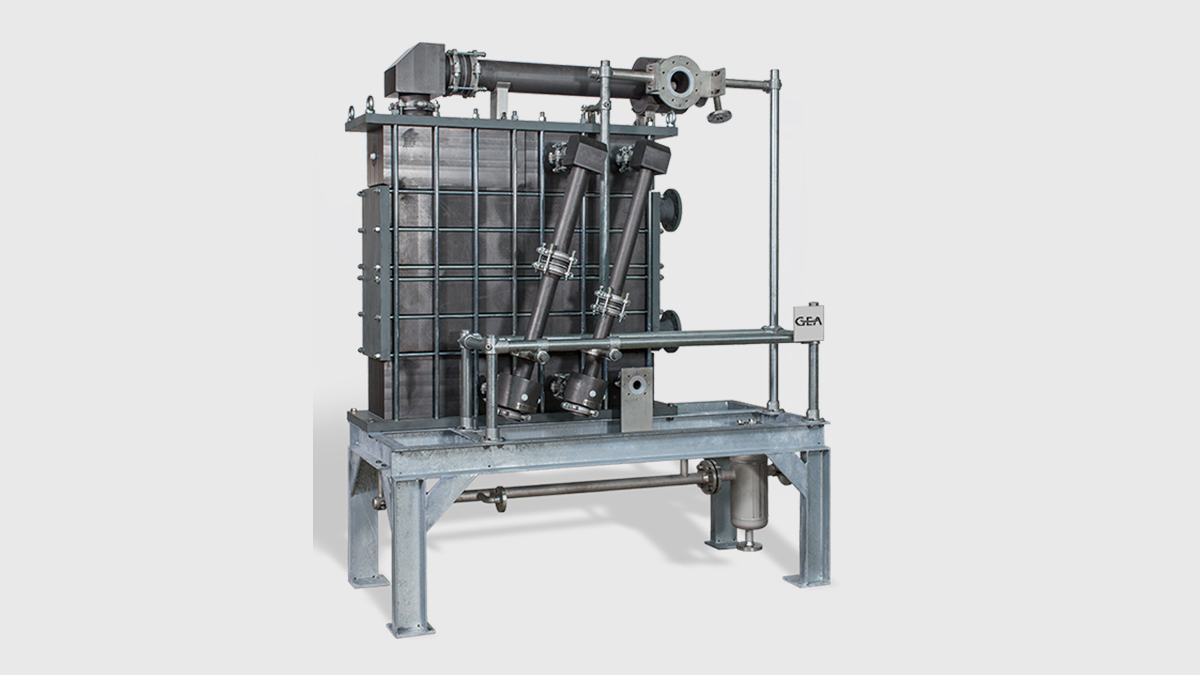

High Corrosive Resistant Vacuum Systems

Multi-stage steam jet vacuum pumps in graphite for corrosive applications.

Variable - Flow Ejectors

Variable - Flow Ejectors are based on proven GEA jet pump technology and often used for heat recovery.

Steam jet compressor

Steam jet compressors type bv1 are based on proven jet pump technology and often used used in evaporating, distillation, cooling, crystallization, deodorization, degassing and drying under vacuum.

Liquid jet liquid pump

Liquid jet liquid pumps are used for conveying and mixing liquids such as water, acids or lye in water and waste water treatment plants.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.