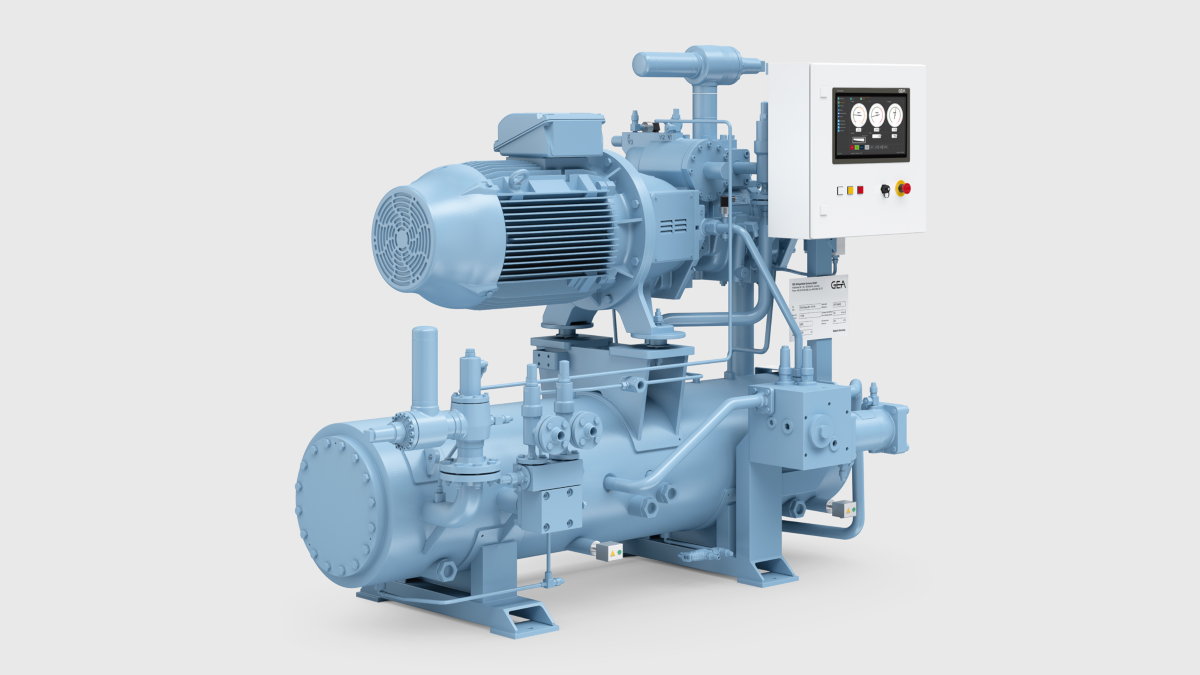

GEA Grasso M series

GEA Grasso M series

The GEA Grasso M series comes in eight sizes with a swept volume ranging from 231 to 870 m³/h (at 2,940 rpm).

GEA Grasso M series – H/L/M/N model

The integration of the suction filter and coupling housing greatly simplify assembly of the package. The outstanding energy-efficiency of these compressors is based on the infinitely adjustable capacity combined with the extended variable Vi-range (internal volume ratio). The variable speed from 1,000 to 6,000 rpm ensures a wide operation range and maximum efficiency in full and part load.

Highlights & Technical Features

- Outstanding energy-efficiency

- Easy package assembly

- Designed for ammonia (R717) and all other common refrigerants

- Available according to API 619 and ISO 10440 standard

- Swept volume: 231 – 870 m³/h at 2,940 rpm

- Speed range: 1,000 - 6,000 rpm

- Design pressure: 28 bar, 52 bar

| Compressor type | Swept volume

(m³/h) | Cooling capacity (kW)

28 bar compressor¹) | Cooling/heating

capacity (kW) 52 bar compressor¹) | |||

| 2940 rpm | 4500 rpm | R717,

-35/+35 °C ²) | R717,

0/+35 °C | R744,

-50/-5 °C | R717,

+35/+80 °C | |

| C | 231 | 354 | n/a | n/a | n/a | n/a |

| D | 265 | 406 | n/a | n/a | n/a | n/a |

| E | 321 | 491 | n/a | n/a | n/a | n/a |

| G | 372 | 569 | n/a | n/a | n/a | n/a |

| H | 471 | 721 | 115 | 444 | 486 | 1.258 |

| L | 544 | 833 | 133 | 513 | 562 | 1.457 |

| M | 708 | 1.084 | 174 | 673 | 743 | 2.202 |

| N | 870 | 1.332 | 215 | 828 | 914 | 2.474 |

| ¹) at 2940 rpm with 5 K superheat and 0 K subcooling, stated temperature values:

evaporation/condensation ²) with economizer | ||||||

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.