Arla to enter new cheese export markets using GEA membrane filtration solutions

With beginnings rooted in the 1880s when Swedish and Danish dairy farmers first started forming small cooperatives, Arla Foods is today a major international dairy organization owned by approximately 8,000 farmers across Denmark and Sweden, the UK, Germany, Belgium, Luxembourg and the Netherlands.

Arla Foods has always focused on offering great quality dairy foods produced through sustainable farming, and in 2019 committed to achieving Carbon Net Zero by 2050 (and by 2045 in Sweden). The cooperative is the world’s largest manufacturer of organic dairy products and strives to respond to consumer and market expectations, launching its first plant-based product range ‘JÖRĐ', in 2020.

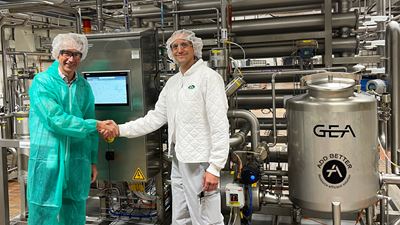

When one Arla Foods manufacturing site at Kalmar, Sweden wanted to increase production of cheeses for trade and international export, the business came to us here at GEA to supply key membrane filtration equipment for brine sanitation that would allow it to meet stringent international standards for microbiological control.

300% increase in the production volume

“This project has not only led to a considerable improvement in our working environment but has also served as a key enabler for a remarkable 300% increase in the production volume of trading/export cheese. The impressive microbiological reduction, with a ≥ 99.8% decrease in yeast and mold, underscores the effectiveness of GEA's technology and professional customer relation skills.”

Tomas Ekvall

Operations Support Manager

Arla Kalmar

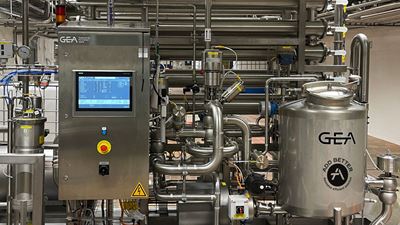

Our COLDSAN® microfiltration unit utilizes state-of-the-art polymeric membranes to provide what we believe is the most effective method of cheese brine sanitation. The unit physically clears molds and other yeasts, bacteria and dead cells, without the requirement for heating or any additional enzyme use. The COLDSAN® system can be built into new cheese lines or retrofit into existing GEA and third-party process lines, helping to ensure safe manufacturing for high-quality cheeses that retain all their nutrition, flavor and texture.

The Arla Foods Kalmar site in Sweden processes about 150 million kilos of milk per year into a wide range of cheeses, including World Championship award-winning products. Manufacturing many national and regional favorites that were distributed primarily to domestic markets, Kalmar was also ideally set up to create cheeses that would be ripe for export.

As recently as 2022 the Kalmar facility was using a brine sanitation system that relied on a traditional method of filtration using kieselguhr (diatomaceous earth) for clearing cheese brine of molds and yeasts. While this well recognized system is perfectly adequate for producing cheeses for the home market, it didn’t meet regulatory requirements for exporting to certain of Arla’s target markets, which mandated greater than 99.8% microbiological clearance.

GEA has a longstanding relationship with multiple Arla sites, including one of the organization’s production units in Sweden that already had a COLDSAN® system installed. Arla Kalmar used this as a reference, making the decision to select GEA COLDSAN® technology as the optimum solution that would allow it to produce cheeses that meet regulatory requirements for export.

Built in the 1950s, Arla Foods Kalmar runs process lines originally supplied by a third party. Our membrane filtration specialists at GEA Skanderborg, Denmark, worked closely with Arla to understand the site’s exact needs, and configure a fully automated COLDSAN® microfiltration unit that could be integrated seamlessly into the existing setup.

GEA and Arla recognized that an addition to satisfying the regulatory requirements for microbiological control, replacing the legacy kieselguhr system with GEA COLDSAN® technology could also help to reduce the plant’s environmental footprint and save on costs associated with cheese brine clean-up and disposal.

Arla Kalmar - Sweden

We extend our heartfelt gratitude to the representatives from GEA, for exceptional project managing, customer relations skills, incredible knowledge in filtration technology and a seamless implementation. Thank you all for the great cooperation – your contributions have made a lasting impact.

Tomas Ekvall

Operations Support Manager - Arla Kalmar

Enabling a throughput of about 5,000 liters per hour, the COLDSAN® microfiltration unit has effectively increased by 300% the volume of cheese that Arla Kalmar can produce for trade and export. Importantly, microfiltration using our polymeric membrane technology results in a much better comparative quality of brine, with improved lifespan.

The fully automated, plug and play COLDSAN® technology is also inherently user friendly, creating a better working environment and freeing up time for operators to focus on key tasks in the plant.

We look forward to continuing our partnership with Arla around the world!

"We have a longstanding relationship with Arla, but every project represents a new beginning. The Arla Kalmar team had prepared all the relevant process, product and operational insights and data we needed to understand their needs. This meant we could work together to design and configure the best brine sanitation (COLDSAN®) system for their requirements, as seamlessly as possible. Completing this installation on time, and to budget, is another great achievement for everyone involved. We look forward to continuing our partnership with Arla around the world!"

Daniel Frosterud

Head of Sales, Liquid and Powder Technologies, Sweden/Finland

GEA

The COLDSAN® system delivered to Kalmar was installed by Arla’s local contractors in just two weeks. After a brief, two-week commissioning period by GEA, the plant came on stream at the end of 2023, and commercial cheese production using the COLDSAN® unit was under way. In fact, the whole project was completed on time and to budget in under a year, from our first mutual sit down with pen and paper in November 2022, to the start of commercial cheese production with the COLDSAN® unit in operation, by Christmas 2023.

GEA Smart Filtration CIP

Reduce the electrical power usage of your membrane filtration process without compromising the effectiveness of your cleaning process.

GEA Smart Filtration Flush

Reduce water consumption, demand for sewage capacity and minimize the CIP time of your membrane filtration processes with smart sensor technology.