Efficiency at higher degrees

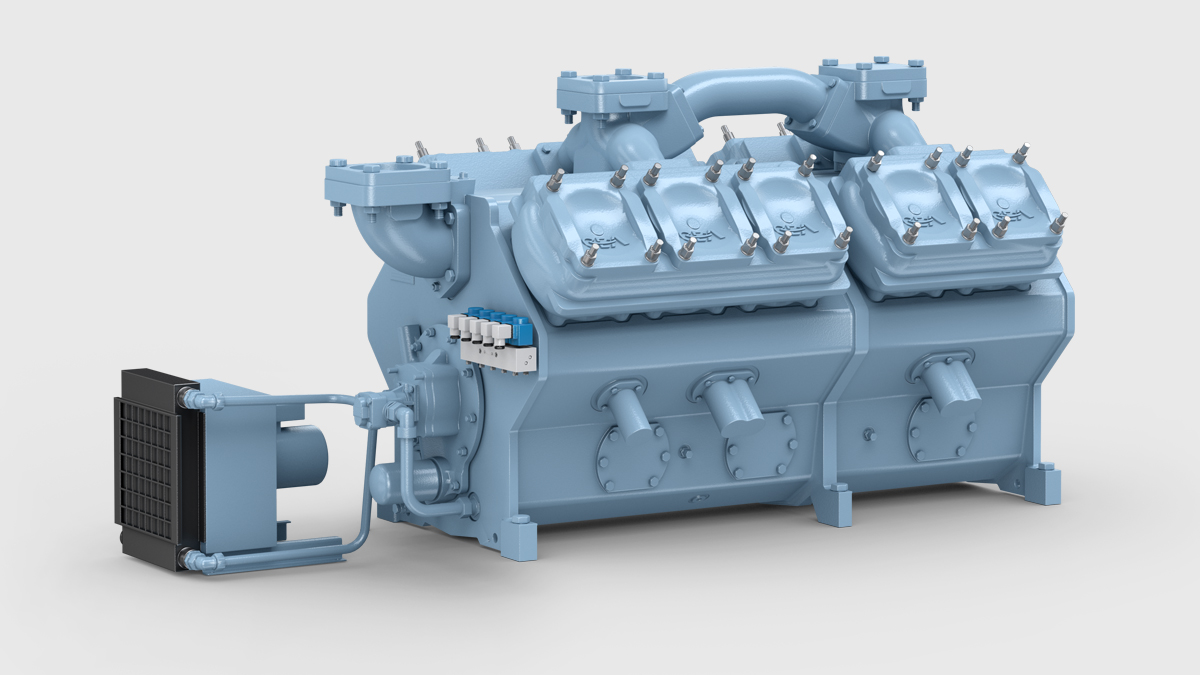

GEA Grasso V HP package

High pressure reciprocating compressor packages for ammonia heat pump applications.

The GEA Grasso V series stands for reduced total cost of ownership (TCO) thanks to less power consumption and maximum reliability. This proven high-efficiency concept is now also available for heat pump applications.

The GEA Grasso V HP series introduces ammonia reciprocating compressors with a maximum design pressure of 39 bar. This makes these new models the first choice for all hot water applications up to 70 °C to meet most industrial requirements in the food industry and elsewhere, especially for cleaning and processing.

An external oil pump on the new models ensures pre-lubrication and a guaranteed continuous oil flow for maximum reliability in full and part load.

The state-of-the-art GEA Omni Control Panel with built-in control apps unlocks the sophisticated operating options of the compressor.

A further step towards Industry 4.0. is the unique Continuous Status Analysis (CSA) function for measuring operating conditions and alerting the operator in case of deviation from normal values.

In short, the new V HP is true to its roots in the V series philosophy, which has efficiency in its DNA.

Highlights and technical features

- Safety: Internal double back-pressure-independent overflow valves

- Efficiency: Highest COP (coefficient of performance) due to maximum-efficiency V series design

- Environment-friendly: Zero GWP due to exclusive use of NH₃ refrigerant

- Reliability: Heavy-duty power drive train

- Reliability: Pre-lubrication with external flanged oil pump

- Reliability: State-of-the-art GEA Omni Control Panel

Learn more with GEA RTSelect – our product selection and configuration tool.

| Model | Total swept volume at full

load, 1,500 rpm (m3/h) | Heating capacity (kw)

R717 | 25/70 °C | Total numbers of

cylinders | Cylinder bore

(mm) | Piston stroke

(mm) |

| GEA Grasso V 300HP | 290 | 569 | 4 | 110 | 85 |

| GEA Grasso V 450HP | 435 | 893 | 6 | 110 | 85 |

| GEA Grasso V 600HP | 580 | 1,190 | 8 | 110 | 85 |

An award winning solution: GEA Grasso V HP for the largest poultry meat producer in Nothern Ireland

Kenneth Hoffmann, PTC Refrigeration Process (Mitte), nahm für GEA den RAC Cooling Industry Award entgegen. (Foto: RAC Cooling Industry)

The British Refrigeration & Air Conditioning Magazine (RAC) has awarded GEA with the RAC Cooling Industry Awards in the category "Building Energy Project". The globally renowned award honors companies that are particularly committed to environmentally friendly and innovative solutions in the refrigeration and air conditioning industry.

Read our full story here

GEA Grasso V HP

Downloads

Verwandte Produkte

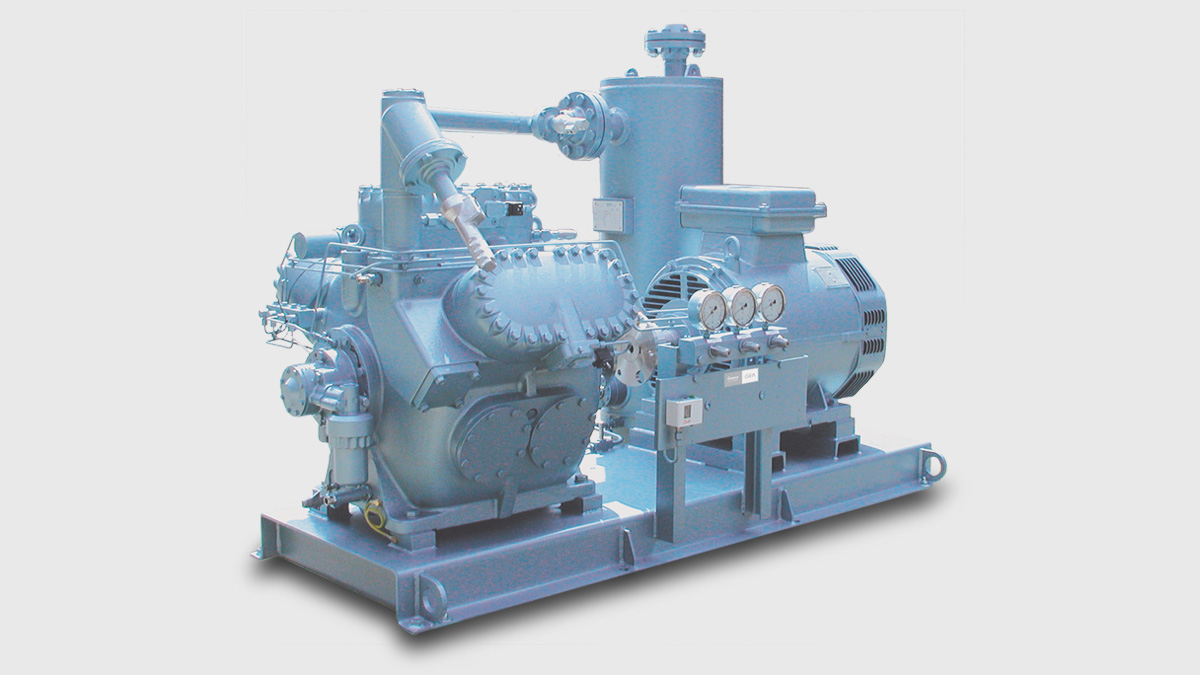

Aggregate der GEA Grasso V Serie

Ein- und zweistufige Hubkolbenverdichteraggregate

GEA Grasso V HS

GEA Hubkolbenverdichter für die Industrie bieten verringerte Gesamtbetriebskosten dank geringeren Stromverbrauchs und maximaler Zuverlässigkeit.

GEA Grasso 5HP Aggregatebaureihe

Einstufige Hubkolbenverdichteraggregate

GEA Insights

Gefriertrocknung in der Pharma-Branche: Alle Vials sind gleich! Oder?

Nur eine Zeiterscheinung oder die Zukunft? In jedem Fall wird die hundertprozentige Nachverfolgbarkeit von Vials für pharmazeutische Unternehmen, die Gefriertrocknung einsetzen, ein zunehmend wichtiges Thema. Wir bei GEA verfolgen diese Entwicklung aufmerksam und prüfen mögliche Lösungen. Vor allem aber verfügen wir über die Erfahrung, den Sachverstand und das Know-how, sie umzusetzen.

Es geht auch ohne: Alkoholfreies Bier kommt an

Es gab Zeiten, in denen die Worte „alkoholfreies Bier“ und „schmeckt gut“ kaum je im selben Atemzug genannt wurden – schon gar nicht von den Konsumenten. Doch alkoholarme und alkoholfreie Biere haben eine enorme Entwicklung hingelegt und sind heute vielfach als Erfrischungsgetränke etabliert. Nicht zuletzt dank der Technologie von GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.