The neXt level of Automation

Automation & Controls Separation

Machine automation solutions for GEA separators and decanters

Serviceability

Excellent equipment is one thing, the right service is another. GEA supports you throughout the entire life cycle of your installation. Customized Service tools enable a perfect insight into the control to operate your equipment under optimal conditions.

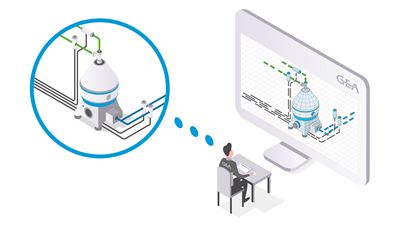

GEA UC app and cloud monitoring services

GEA controls provide you with complete machine data online. Optional GEA Cloud® server solutions and customized dashboards via our GEA UC app show machine status, process data, trends, alarms, etc. Always and everywhere!

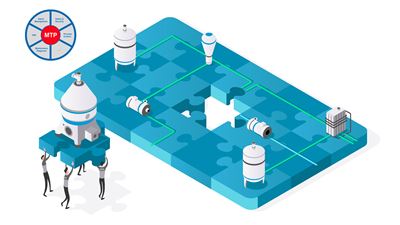

Enhanced connectivity by MTP

Modular and highly flexible production requires modular automation. GEA offers Module Type Packages (MTPs) that contain all the information required for easy implementation in customers' production lines.

Cyber security

The digitalization of industrial production poses an increasing risk of cyber attacks. Cyber security is a highly sensitive domain in which GEA is your reliable and certified partner.

Software quality

What has been modified is saved. Who did what, why, when and where? Full transparency of the change process during development, testing, acceptance test and commissioning ensures highest software quality.

High availability of controls

Industrial applications are facing a continuously increasing degree of automation.As a result, the availability of controls becomes significantly important. GEA covers this with special hardware in hot standby mode.24 hours a day, 7 days a week, 365 days a year.

Regulations / certifications

The topic of safety plays a crucial role in automation and controls for GEA centrifuges. GEA offers this safety – no matter where and for which application – whether for complex projects for process lines or for supposedly simple tasks on independent machines.

Simulation

Even small installations are becoming increasingly complex. Unexpected challenges often escalate commissioning procedures. Virtual commissioning by simulating a complete separator installation using a digital twin avoids additional time and costs.

GEA IO

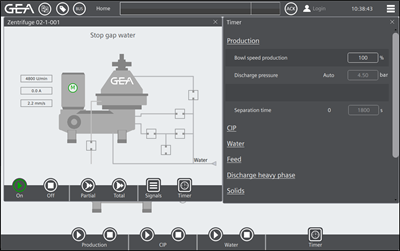

GEA IO – One control for every centrifugeThe control system GEA IO has been designed as intuitive as possible. Displays have been consistently streamlined, the symbols are self-explanatory, and the color code is based on international standards.GEA IO for all GEA Separators and Decanters

In order to reduce complexity and to focus on user-friendliness, GEA IO control is available for every GEA separator and decanter – for every kind

Next to control and display reliable data, GEA IO is able to capture and evaluate data. GEA IO ensures a safe and reliable operation to maximize the performance and availability of your centrifuge.

Preventive service indication

Excellent equipment is one thing, the right service is another. With several options of the service concept “GEA Service – For your continued success”, GEA supports you throughout the entire life cycle of your installed systems and components. GEA IO allows you to have a perfect insight into the maintenance schedules to run your equipment in the most optimal conditions.

Size matters

GEA IO is able to offer much more than today`s control units. This means, that a wide range of sizes is now available in a much more intuitive manner suiting your specific needs. GEA touch panel available sizes are 4, 7, 9 and 15 inch.

GEA IO installed on a decanter

GEA X Control

GEA X Control - The neXt level of automationIntegration, connectivity, data processing, security – GEA X Control takes automation solutions for centrifuges to the next level. The new centrifuge control from GEA Separation utilizes the technological progress in digitalization to address shifting customer needs.

GEA X Control

GEA X Control speaks MTP

The new interface for centrifuge controls

MTP (Module Type Packaging) is the fastest and easiest way to integrate new equipment and process stages into existing process lines and the overall process control system. No more burdensome exchange of long data lists and hardware contact descriptions to integrate your centrifuge into your on-site SCADA-system. The MTP interface provides all necessary data and improves the interoperability and standardization of automation systems, independent of manufacturer and technology. MTP is faster, less expensive and you are much less dependent on highly specialized experts.

New functions require more performance and that’s exactly what GEA X controls offers. Customers not only expect maximum yield and throughput capacity as well as top product quality from their centrifuges, sustainability aspects like energy and water consumption and the overall CO2 footprint become more and more important. GEA X control and its highly increased data processing capacity is able to handle all those data.

GEA Cloud® connectivity and Edge computing

With the GEA UC app you have access to your centrifuge data wherever you are, whenever you want to

GEA Cloud® connectivity via IoT gateway gives you access to your process data from wherever you are, whenever you want to. Cloud server solutions by GEA show your machine status, process data, trends, alarms - whether it is an upgrade for an existing machine – installed in an instant - or a brand-new installation. With standardized or customized dashboards, you are always aware of all real-time as well as trending and historical stored machine data.

But not only cloud computing will be easier in future, X control opens up new possibilities for Edge Computing just as well. Processing power can be easily increased locally and used to implement new interfaces for integration into process line control systems. In addition, this involves the integration of AI algorithms - that is, the control system begins to learn, recognize patterns and draw conclusions. Thus both, our customers and GEA X Control are ready for Software as a Service.

Safe, safer, GEA X Control

It’s all about security: GEA's understanding of safety starts with the development processes for automation solutions. They are TÜV-tested and certified according to IEC 62443-4-1. With the new GEA X Control generation, various optional cyber security levels are added - adapted to individual customer requirements. For example, every control system runs an operating system, if there are security warnings from the manufacturer, an update is required immediately. With security update management, our customers are on the safe side with GEA X Control.

Automation and control systems for GEA centrifuges

Downloads

Service Products

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

Related Videos

Let’s get connected – digital solutions for GEA separators and decanters

Stay stronger with GEA Service Level Agreements

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.