The major plus in protein yield

GEA proplus

GEA proplus extends the ejection intervals of milk separators from 20 – 30 minutes to up to 90 minutes. This ensures added value, a significant increase in protein yields from the quantity of milk used and a clear reduction in fresh water consumption and waste water creation.

New installation or modular retrofitting

GEA proplus offers two options to make your milk processing more profitable: a new installation of GEA separators with integrated proplus system, or specific retrofitting of systems which are already installed.

Proplus in action!

Higher protein yield and safer operation because of proplus:

With GEA proplus you can obtain up to 3 times less shots, up to 3 times less sludge volume, a high reduction of product waste and you can save up to 28% water. Please contact us so we can check together, based upon your production data, what GEA proplus can do for you!

If you want a quick check please use the calculator on this page.

Always benefit twofold: Flexible investment, optimized operating costs

In addition to the additional protein and environmental protection, you also increase your productivity with proplus by means of greater system availability, lower maintenance and wear costs, and longer machine service life.

GEA proplus Maximize protein yield, minimize water consumption

GEA Dairy Proplus Productivity Boost

From the outset, you can count on additional profits from the raw milk used, reduced operating costs and hence faster amortization of your new investment.

GEA proplus is designed for hot & cold milk separation and bacterial removal from 3,000 l/h throughput capacity onwards.

GEA proplus calculator

The calculator above calculates possible annual savings by buying GEA proplus. Results are purely indicative and non binding.

GEA proplus technology

Downloads

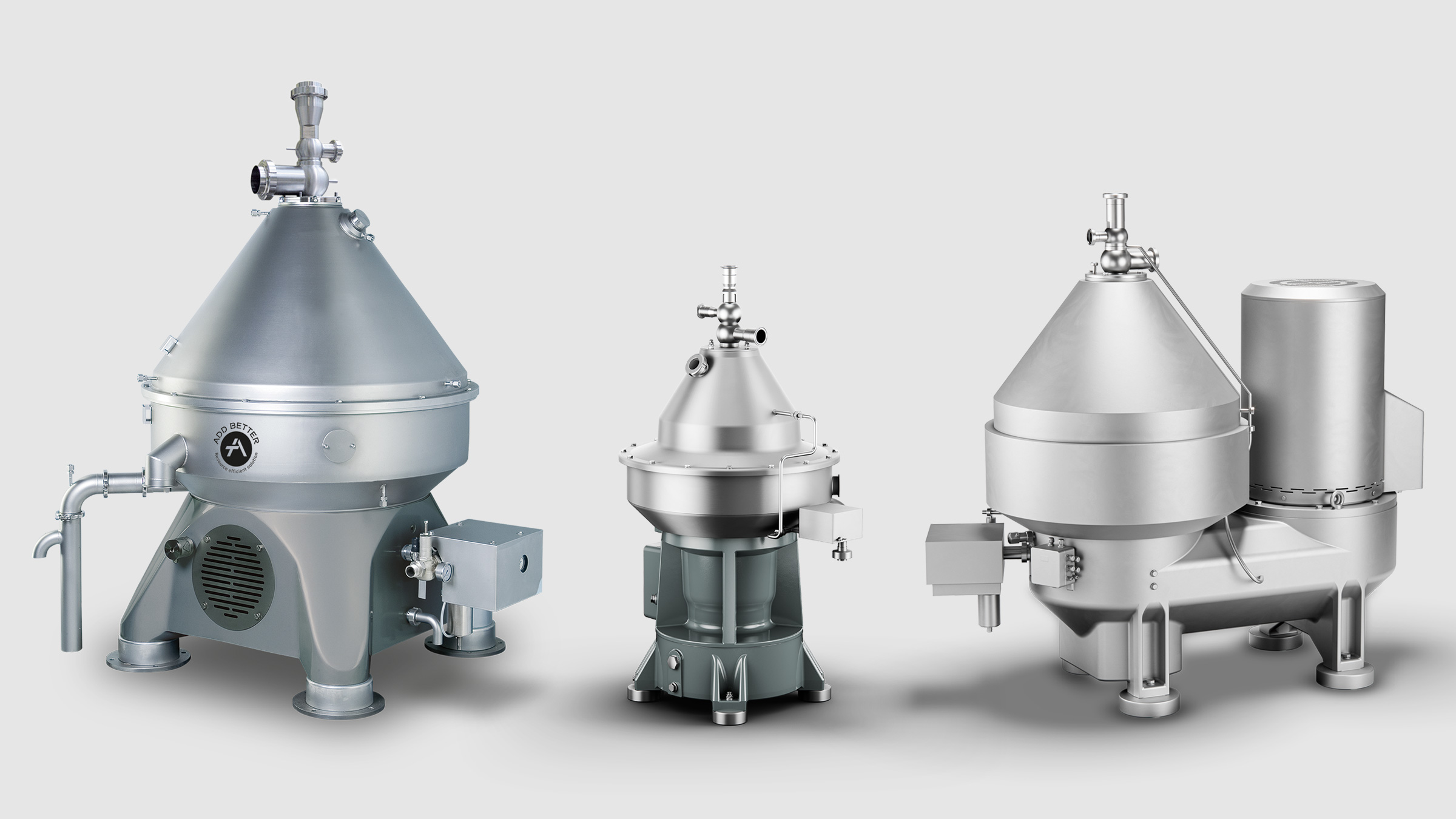

Related Products

Bacteria Removal Separators for Milk and Whey

Bacteria removal separators from GEA efficiently remove bacteria and spores from the raw and vat milk and whey.

Separators for Milk and Whey Skimming

GEA offers a comprehensive centrifuge portfolio for the skimming and standardization of milk and whey from various farm animals.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.