Reciprocating Compressor Systems

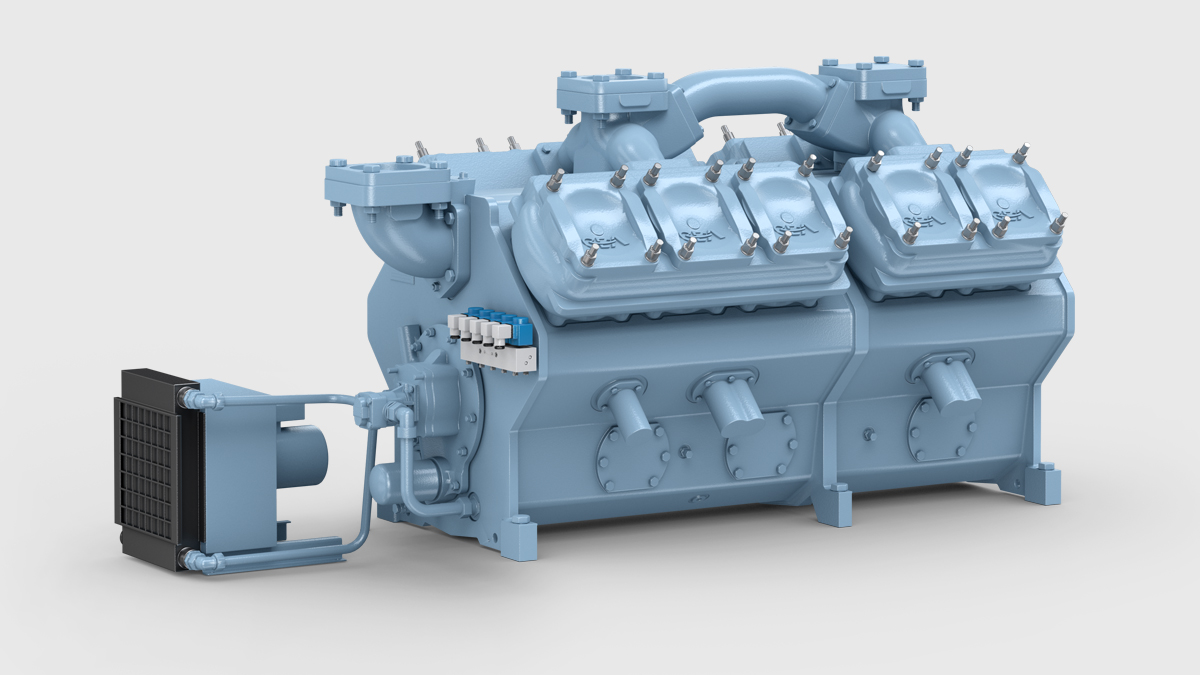

GEA Grasso V HS

High speed reciprocating compressors for more capacity

It offers a higher refrigeration capacity against a lower investment. The speed increase provides clients with a significant increase in capacity. Because of the proportional correlation of compressor speed, swept volume and resulting capacity, 25 % more capacity can now be gained using the same models. That returns a significant improvement (reduction) of the relative price as in Kilowatts per Euro. Alternatively, users with a specific, fixed capacity requirement can benefit from the higher speeds by allowing them to achieve the capacity demands with smaller compressor equipment meaning less investment and less service expenses Compressors at higher speeds offer significant savings potentials for your Total Cost of Ownership, reduced footprint and CO2 emissions.

Highlights and technical features

- Increased capacity. providing more capacity, reducing investment costs

- Extended speed range up to 1,500 rpm

- Reduced fooprint, using smaller compressors at higher speed

- Environment-friendly, zero GWP (Global Warming Potential) due to exclusive use of the natural refrigerant NH₃ (ammonia)

GEA RT Select – our selection and configuration program will help you to find the right equipment for your refrigeration and heating plant.

Technical data

| Single stage | Number of

cylinder | Standard speed

(rpm) | Swept volume

(m3/h) | Cooling capacity

-10/+35 °C (kW) |

| GEA Grasso V 700HS | 4 | 1,500 | 796 | 459 |

| GEA Grasso V 1100HS | 6 | 1,500 | 1,194 | 688 |

| GEA Grasso V 1400HS | 8 | 1,500 | 1,593 | 917 |

| GEA Grasso V 1800HS | 10 | 1,500 | 1,992 | 1,146 |

Downloads

Related Products

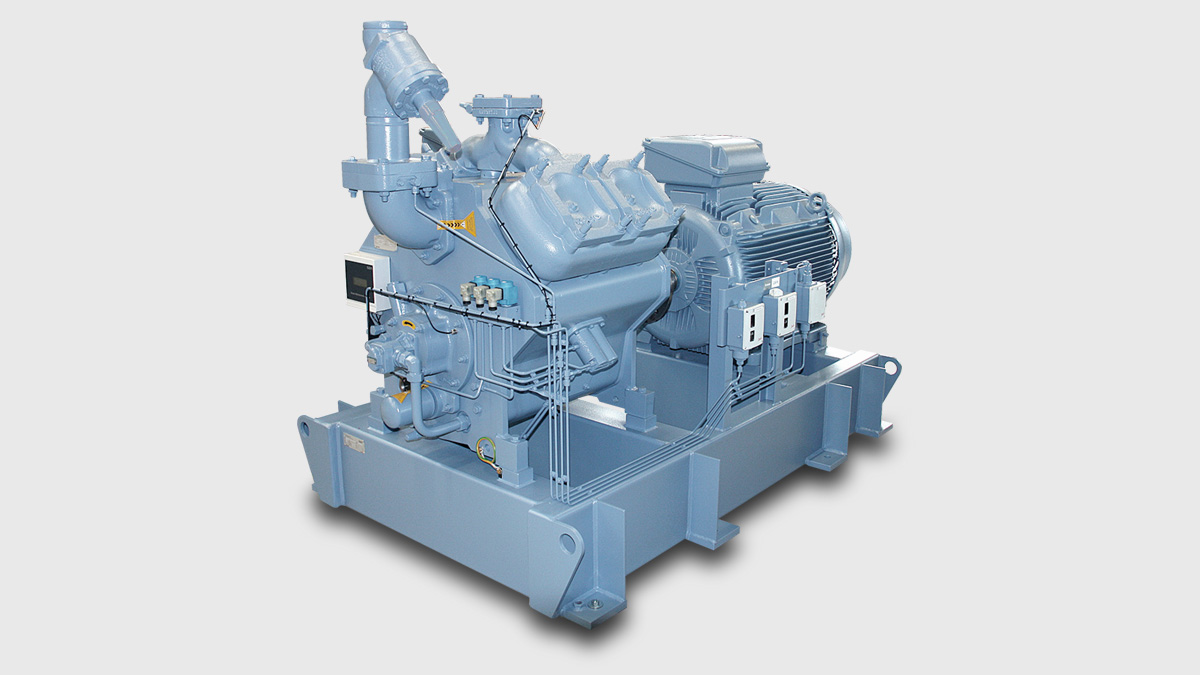

GEA Grasso V series packages

Single- and dual-stage reciprocating compressor packages.

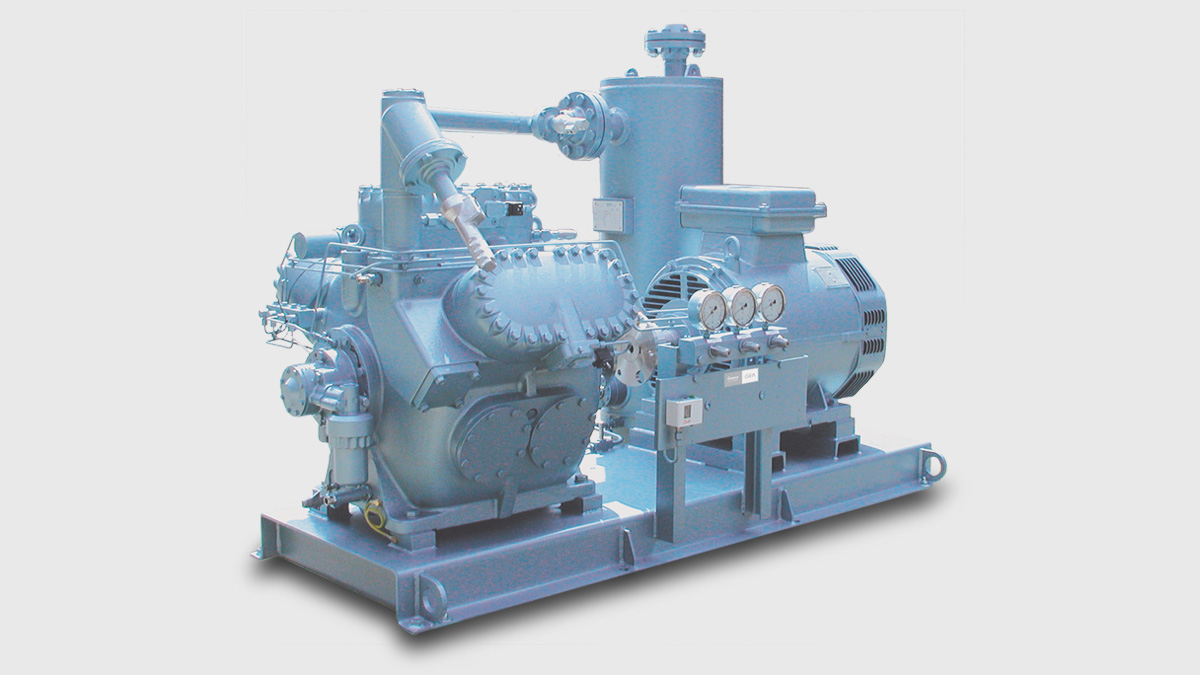

GEA Grasso V HP package

High pressure reciprocating compressor packages for ammonia heat pump applications.

GEA Grasso 5HP series packages

Single-stage reciprocating compressor packages.

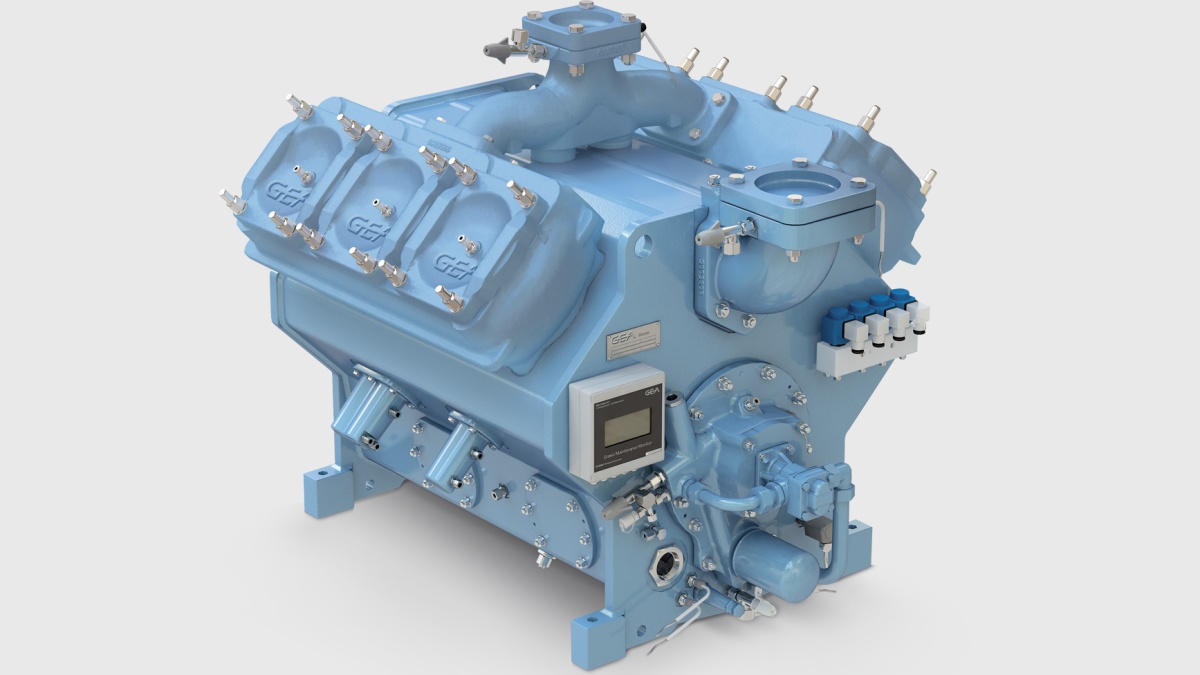

GEA Grasso V series

Reciprocating compressors for industrial refrigeration

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.