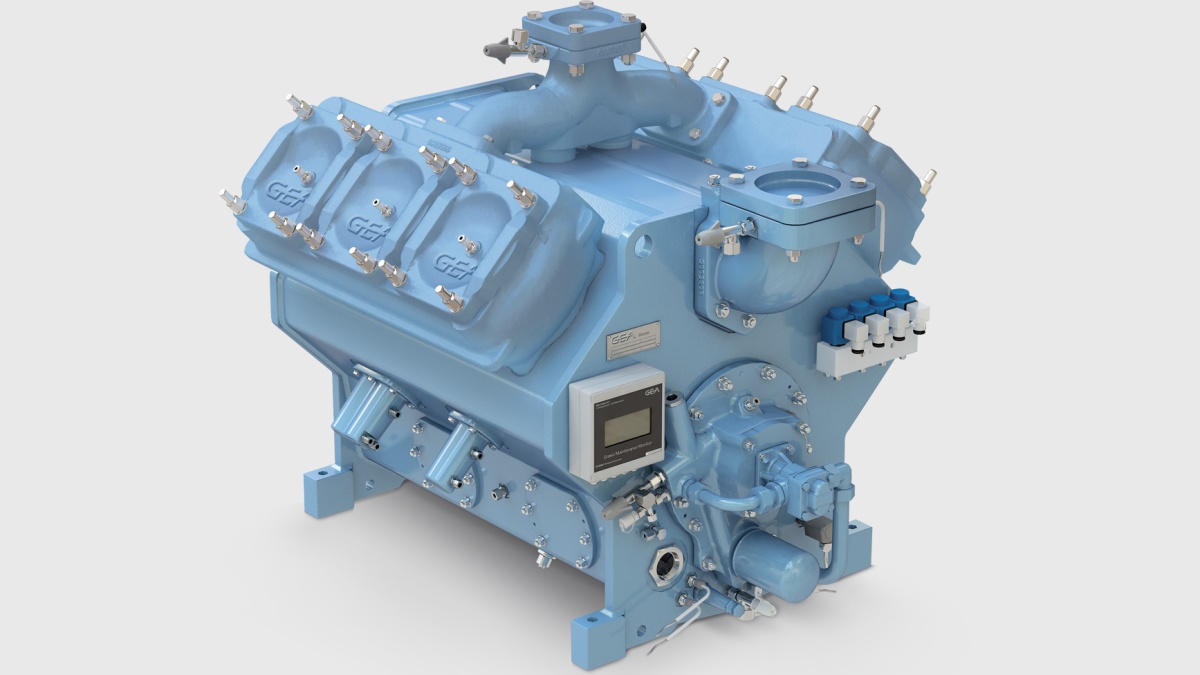

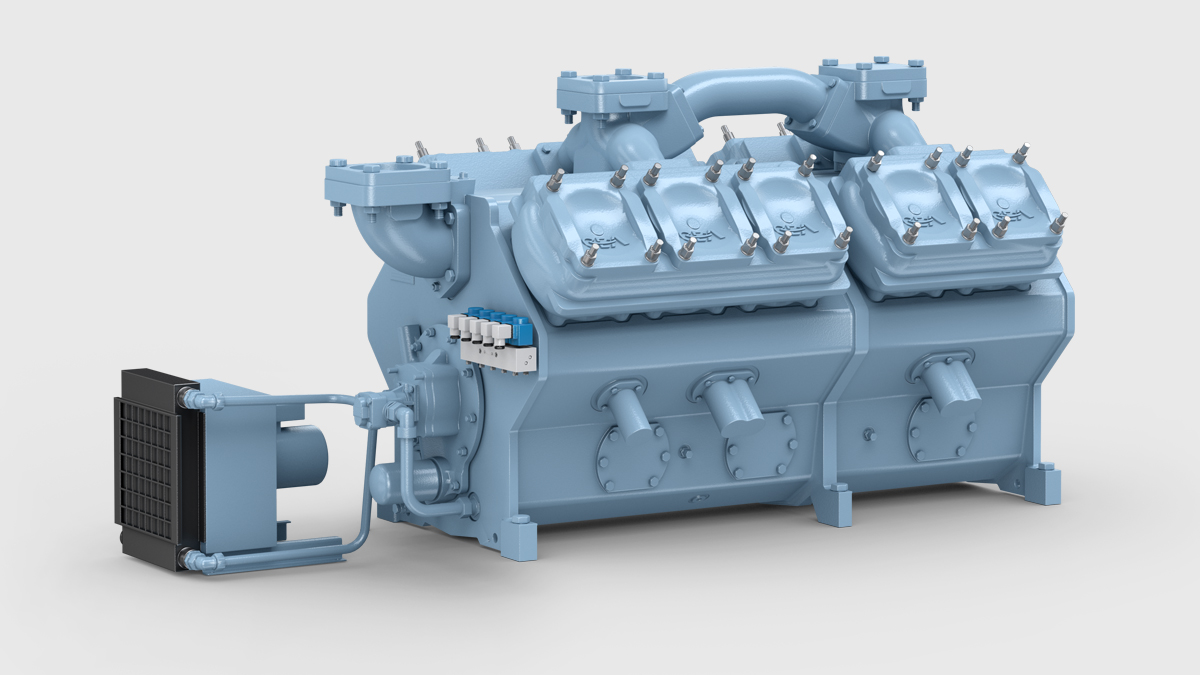

Reciprocating Compressors

GEA Grasso V series

Reciprocating compressors for industrial refrigeration

Features of GEA Grasso V Series

- Unique steel welded compressor housing

- No water cooling required

- Extended and flexible maintenance intervals

- Maintenance monitor for indication of upcoming service intervals

- Heavy duty axial roller bearing

- Counter pressure independent overflow valve

- Capacity control steps per cylinder

- Suitable for speed control

- Peek technology for high efficiency and long valve life time

- Low noise level

- Lowest Total Cost of Ownership (TCO)

- Refrigerant: NH₃

| Models | Swept volume*

(m³/h) | Cooling cap. (kW)** NH₃ | Dimensions

(mm) | Weight

(kg) | ||

| 0/+40℃ | L | W | H | |||

| Single stage | ||||||

| GEA Grasso V 300 | 290 | 237 | 882 | 933 | 922 | 575 |

| GEA Grasso V 450 | 435 | 355 | 1076 | 933 | 922 | 751 |

| GEA Grasso V 600 | 580 | 474 | 1363 | 933 | 922 | 1042 |

| GEA Grasso V 700 | 637 | 549 | 1062 | 1076 | 1013 | 794 |

| GEA Grasso V 1100 | 955 | 823 | 1306 | 1076 | 1013 | 1054 |

| GEA Grasso V 1400 | 1274 | 1098 | 1666 | 1076 | 1027 | 1495 |

| GEA Grasso V 1800 | 1592 | 1372 | 1909 | 1076 | 1027 | 1725 |

| Models | Swept volume*

(m³/h) | Cooling cap.

(kW)** NH₃ | Dimensions

(mm) | Weight

(kg) | ||

| -40/+35 °C | L | W | H | |||

| Two stage | ||||||

| GEA Grasso V 300T | 217 | 34 | 935 | 940 | 922 | 590 |

| GEA Grasso V 450T | 290 | 52 | 1310 | 940 | 922 | 769 |

| GEA Grasso V 600T | 435 | 68 | 1425 | 940 | 922 | 1062 |

| GEA Grasso V 700T | 478 | 85 | 1060 | 1072 | 1013 | 814 |

| GEA Grasso V 1100T | 637 | 123 | 1304 | 1072 | 1013 | 1077 |

| GEA Grasso V 1400T | 955 | 170 | 1672 | 1072 | 1027 | 1520 |

| GEA Grasso V 1800T | 1114 | 203 | 1874 | 1072 | 1027 | 1755 |

* Theoretical swept volume based on low stage cylinders

** Based on: 0K subcooling, 2K superheat (non-useful)

*** Cooling capacity based on open flash interstage cooler system (GEA Grasso system “C”)

Keeping cool at Godden Food in Australia

Downloads

Related Products

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Grasso V HS

GEA’s industrial reciprocating compressors stand for reduced total cost of ownership (TCO) thanks to less power consumption and maximum reliability.

GEA Grasso 5HP series

Reciprocating compressors for CO2 freezing and NH3 heat pump applications.

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.