Significantly improving Potash quality and process efficiency.

Potash Conditioning System

The GEA Potash Conditioning System features a conditioning drum and fluid bed for glazing, polishing and drying of granular Potash which significantly improves product quality and operating efficiency. The lifters, drum angle, spray pattern, rotation speed and residence time can be adjusted meet the required product specification.

The GEA Potash Conditioning System

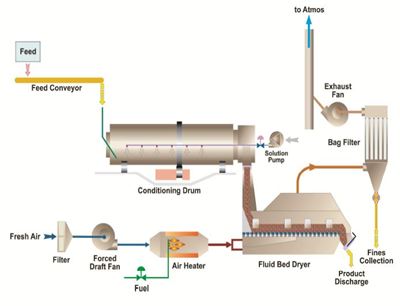

The product potash feed from the client's upstream process is introduced to the conditioning drum at a continuous and stable feed rate with consistent moisture content and temperature. As the particles travel through the drum, spray water nozzles glaze and condition the potash with a fine misting of water for uniform product coating, while the drum promotes rapid product tumbling for optimal polishing.

The wetted product is subsequently discharged directly into a fluid bed dryer via a discharge chute. The material is distributed across a sloped directional fluidizing bed plate which propels the material towards the discharge end of the fluid bed. The plate is dimensioned to provide plug flow, allowing an optimal degree of fluidization while upward airflow prevents material from falling through to the lower plenum. An adjustable underflow discharge gate valve controls the material bed depth which varies the retention time and enables rapid and complete emptying of the unit.

Process fluidization air is supplied by a forced draft fan and exhaust gases are passed through a baghouse for dust collection before discharge to atmosphere via an exhaust fan. Slightly sub-atmospheric conditions are maintained above the bed by means of a balanced system of forced and induced draught fans which eliminate the need for air seals at the feed and discharge points.

Features

- Efficient and effective surface wetting of the potash granules

- Granules roll over one another in a high humidity environment for the duration of the drum residence

- Rounding of granules without breakage

- Rapid drying

- Evaporative cooling

Benefits

- Ensures even granule coating

- Promotes rounding and hardening

- Minimizes the dust loading of the exhaust air and the reclaimed fines for re-compacting

- Flashes residual moisture off quickly leaving a hard re-crystallized surface

- Reduces energy consumption

Typical Flow Diagram

Downloads

Related Products

Fluid Bed Dryer (Static)

GEA Static Fluid Beds are widely used throughout the process industries for drying, cooling and calcining of powders, crystals and granules.

Rotary Dryers

The GEA Rotary Dryer is extensively used throughout the process industries and is highly reliable under the most arduous operating conditions.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.