Crystallizer technology

Forced Circulation Crystallizers

The most widely used crystallizer thanks to its simple and robust design as well as the easy operation. Its high mechanical energy input and high secondary nucleation rate make it the best solution when large crystals are not required.

The Forced Circulation Crystallizer is the most common type of crystallizer. Simple in design and easy to operate, it is usually employed in evaporative crystallization of relatively flat or inverse solubility products in rather viscous media and when scaling is a major issue. Its highly mechanical energy input and high secondary nucleation rate make it the best solution when large crystals are not required.

Particular Features:

- MSMPR (mixed suspension, mixed product removal) crystallizer

- Suitable for products with relatively flat or inverse solubility curve

- Limited crystal size (<0.8mm) due to elevated secondary nucleation rate

- Single loop or double loop installation for large capacities

- Central pipe or tangential inlets

- Scaling and down-time minimization by surface treatment and reliable flushing concepts

- Auxiliary equipment

- Demister (internal or external) for condensate quality control

- Integrated salt leg for elevated product purity

- Baffle zones (internal or at circulation pipe)

Working Principle

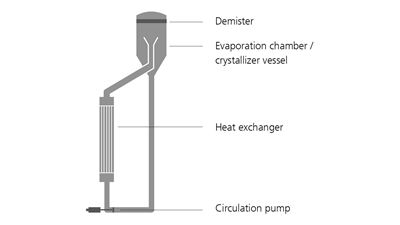

Working Principle of Forced Circulation CrystallizersThe Forced Circulation Crystallizer is made of four basic components:

- The crystallizer vessel. Provides most of the active volume dictated by the residence time requirements and enables a proper disengagement of process vapors.

- The circulation pump. Provides sufficient circulation rate to operate the crystallizer under optimal supersaturation and superheating conditions. Typically, axial-flow propeller pumps are used.

- The heat exchanger. Supplies the required thermal energy to the crystallizer for the desired evaporation rate.

- Interconnecting piping. Connects the components of the crystallizer.

Slurry of a desired solid density is circulated from the crystallizer vessel through the heat exchanger, gets superheated and is returned to the evaporation chamber. The superheating is relieved by means of evaporation and the evolving supersaturation is leading to growth of the suspended crystals. The evaporated solvent is conducted to the subsequent process steps or is internally re-used by applying any re-compression system.

Heating options for thermal separation plants

Downloads

Related Products

Crystallization Test Centers

Available for product and feasibility trials with real samples and under real parameters. Either in GEA centers of excellence for crystallization or onsite thanks to our mobile units.

COMPACRYST®

Process and mechanical innovation. Compact and Monoblock Forced Circulation Crystallizer.

Oslo Crystallizers

Fluidized bed crystallizer with the ability to grow the largest crystals at elevated retention time.

Draft Tube Baffle Crystallizers

Limited attrition and efficient fines destruction – a design to produce coarse crystals with a narrow size distribution.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.