Premium Food Packaging

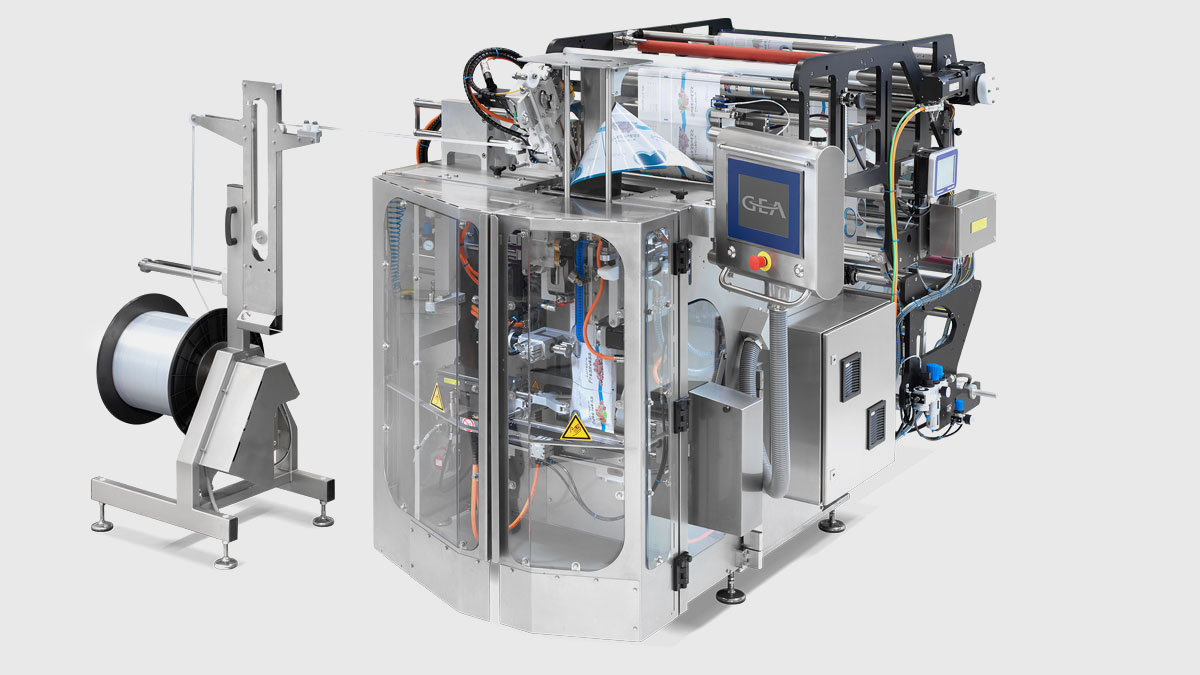

GEA SmartPacker CX400 D-Zip

This continuous motion vertical packaging machine creates re-closeable stand-up pouches for retail and food service. It combines fast, high-quality operation with maximum flexibility and uptime. Apart from producing premium quality D-ZIP bags, this easy-to-use machine can produce more than 10 different bag styles for a wide variety of applications such as candy, nuts, frozen fruits and grated cheese.

Smart in every way

With a newly developed integrated corner seal unit our latest vertical bagger is designed to reduce complexity and improve quality, flexibility and serviceability. Thereby meeting the demands of today’s processors. Users can expect premium performance with an output up to 100 GEA D-Zip bags/minute; enjoy maximum uptime and highly accurate operation from a machine that carries the smallest footprint of any other comparable machine in the industry.

Premium quality, outstanding performance

- Premium quality D-Zip bag with smooth and sharp cross seals and wrinkle-free seals with high density and air/gas-tight sealing

- Backed by GEA’s more than 60 years experience in vertical packaging

- Combining the high-quality of the pouches made on conventional horizontal machines with the advantages of a SmartPacker

Fast, easy and flexible

- Capable of producing all common bag types on a single machine without compromising any expectations

- High uptime and highly accurate operation with the smallest footprint of any other comparable machine in the industry

- Changeover time from standard to D-Zip bag of under 45 minutes, without the use of special tools and features front discharge

- Featured with a newcorner seal unit, which simplifies set-up and improves overall quality

Downloads

Service Products

GEA InsightPartner for food processing and packaging equipment

By providing instant access to real-time equipment data, InsightPartner helps food processors manage their production better. Our cloud-based solution provides advanced analytics and comprehensive insights based on continuous data monitoring.

GEA RemotePartner for food processing and packaging equipment

GEA RemotePartner combines digital machine access and remote support to help you swiftly identify the root cause of any equipment issue and get instant assistance from GEA experts. The result: faster issue diagnostics and resolution, enhanced machine performance, greater efficiency and minimal downtime.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.