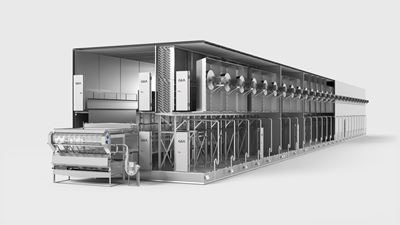

Tunnel Freezers

GEA A-series

Our GEA A-series IQF tunnels can handle up to 30 tons per hour capacity

GEA AD-series tunnel freezer with external fan motors

Large capacities

- Up to 30 tons per hour freezing capacity

Multiple temperature zones

- Pre-cooling

- Refrigerating

- Freezing

Hygienically engineered design

- Fully welded stainless steel floor, enclosure and structure

- Ample access to all components

Energy saving solutions

The IQF tunnel freezer range design for French Fry applications includes energy savings and energy recovery features with a minimum of 22% reduction of CO2 emissions from water precool system certified by the EU-Taxonomy classification.

- Precool section using thermosyphon ammonia. No refrigerating compressors required.

- Precool section using plant water heated from +15°C to +22°C. Energy saving in the factory hot water system.

- Freezing section using ammonia at -32°c. More than 20% energy saving in comparison with -40°C evaporating temperature.

IQF Tunnel Freezer for Potato Application

High product quality and sustainable freezersThe current challenge for frozen potato processors is to reduce energy and meet sustainability targets in an effective way.

A significant amount of energy is required to freeze potato products. For a 30,000kg/hr French fry freezing tunnel, about 6MW of refrigeration capacity at different temperature levels is needed to gradually reduce the product to frozen.

Freezer equipment design is vital for food safety, optimum performance throughout production, and energy savings, especially when handling massive quantities of French fries! Additionally, the right equipment can significantly reduce downtimes with fast, efficient cleaning factored in.

GEA IQF tunnel freezers for potato applications are specifically designed for pre-cooling and freezing process steps with multizone temperature freezer embedding unique features for hygiene, efficiency, high uptime, and reliability. GEA experts in frozen food applications ensure that the best solution is identified for your product and select a tunnel configuration to guarantee quality and safe products throughout your entire freezing process.

GEA IQF tunnel features and benefits

- Customized solution:

- Safe product handling:

- Reduced cleaning time

- Energy savings:

- Long operating time

- Low total cost of ownership

Enabling reductions in CO2 emissions

GEA, a leading technology provider to the food sector has more than 160 of its French fry freezer tunnels operating worldwide and recently conducted extensive research and development into significantly improving the sustainability and energy consumption in industrial freezing equipment.

We recently obtained a certification of CO2 emission reduction for its French Fry IQF tunnel freezer with Water Precool as a result of a proven 22% to 57% drop in CO2 emissions depending on the country and conditions therein.2 Results were certified by Ramboll, an EU Taxonomy evaluation body.

Proven CO2 emission reductions and energy-efficient consumption are part of the sustainable actions to contribute to, and reach GEA Group’s target to align with its Mission 2026 program.

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.