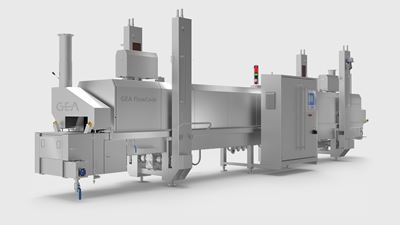

GEA FlowCook

Top cooking and roasting performance on a smaller scale

Effective linear cooking for a wide range of applications

The GEA FlowCook packs the benefits of combined vertical and horizontal airflow into a versatile in-line cooker for low to medium-scale production. It is a dual-zone oven with two independently-controlled temperature and humidity zones that are used for hot air cooking, steaming and roasting. The balanced cooking zones, together with a passive exhaust system, keep heat losses and exhaust steam from the outside to a very low level. The energy consumption is further reduced by optimizing the airflow, maximizing the heat transfer and providing superior thermal insulation. The result is an environmentally responsible solution and low running costs

Main applications

GEA FlowCook is suitable for 400mm and 600 mm wide lines and a wide range of cooking applications. It is an excellent solution for steamed, coated, marinated-enhanced browning, natural roasting, bone-in,boneless or formed products.

Top performance for a wide range of applications

- Extremely flexible, steaming, cooking and roasting in one linear oven

- The ultimate in efficient cooking with combined horizontal and vertical booster airflow

- Maximum uptime, even with the most difficult applications, due to continuous belt wash system

- Lowest variation of product color and core temperature throughout the oven

Process efficiency

- Short cooking time and a higher yield for both coated, marinated-enhanced browning and roasted products

- Spot-on dewpoint control and temperature control in each cooking zone

- Reduced energy consumption from balanced airflow

- Guaranteed performance success from in-house application know-how and technology support

Proven reliability

- More than 35 years’ experience and countless millions of tons of food products produced

- 99% uptime with proven installations around the globe

- Better operating efficiency with global service coverage and support programs

Specifications

Advanced technologySpot-on dewpoint control and temperature control in each cooking zone

The GEA FlowCook combines vertical and horizontal airflow to ensure efficient heat transfer and controlled conditions in the oven. The two independent chambers are balanced and feature an identical (but mirrored) airflow to enable separate cooking conditions to be set up in each zone to accurately control the cooking process. Humidity in each zone is individually controlled by dewpoint, while the airflow is fully adjustable to support a huge range of applications.

Vertical air flow

The high velocity of the vertical airflow in the middle of the cooking process is excellent for browning and roasting; when set to lower velocity, it offers more control over crispiness with very little yield loss. Applying vertical airflow at the appropriate point in the process makes it possible to roast natural and skinless products with little or no color additives.

Downloads

Service Products

Endurlon® guiding strips

Do you want to extend the service intervals of your GEA CookStar? Reduce your maintenance costs? Improve hygiene? Now you can with Endurlon™ spiral oven guiding strips.

GEA InsightPartner for food processing and packaging equipment

By providing instant access to real-time equipment data, InsightPartner helps food processors manage their production better. Our cloud-based solution provides advanced analytics and comprehensive insights based on continuous data monitoring.

GEA RemotePartner for food processing and packaging equipment

GEA RemotePartner combines digital machine access and remote support to help you swiftly identify the root cause of any equipment issue and get instant assistance from GEA experts. The result: faster issue diagnostics and resolution, enhanced machine performance, greater efficiency and minimal downtime.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.