Superior Membrane Filtration Systems

Custom-Designed Filtration Plants

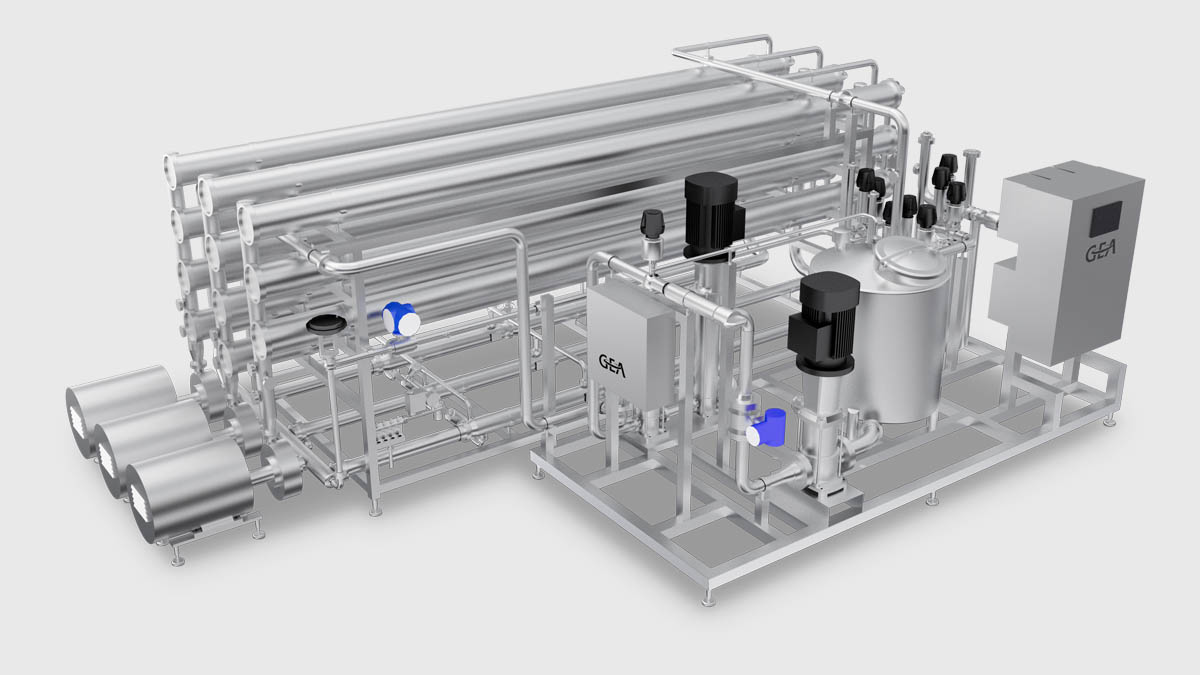

GEA custom designs membrane filtration systems that best utilize the technologies of microfiltration, ultrafiltration, nanofiltration, or reverse osmosis for each customer's specific application.

Membrane Filtration Systems

GEA membrane filtration systems are known worldwide for leading technology, high performance, and energy efficiency. Specific benefits of GEA systems include:

- Superior product quality

- Optimized processes for maximum throughput at minimum investment

- Reduced energy requirements for lower operating cost

- Reliable operation for minimum downtime and increased profits

The scope of supply offered by the GEA Group means that complete turnkey plants, incorporating membrane filtration, can be supplied from a single source. This ensures equipment compatibility, operational efficiency, security of outcome and fast instillation and commissioning GEA also offers complete self-contained pilot plant units for product testing and process development.

Downloads

Related Products

Condensate Polisher

Condensate from evaporation plants is used as boiler feed water, process, cooling, and rinsing water or is directly discharged into a drainage ditch.

For this purpose, the condensate must be purified. Impurities in the condensate can be removed by membrane filtration, in the particular case by reverse osmosis, and high condensate qualities can ...

Beer Recovery Unit

GEA cross-flow filtration with robust ceramic membranes are used for the effective recovery of beer from tank bottoms. Modular plants are supplied on compact skids in three standard sizes with processing capacities of approximately 250 hl, 500 hl and 1000 hl per day depending on the dry solids content of the product.

GEA AromaPlus Membrane Dealcoholization Unit

Supporting small to large feed rates, and configurable for both batch and continuous processes, the dedicated AromaPlus system is built on our reverse osmosis (RO) membrane filtration technology.

Membrane Unit to Produce FAB

GEA’s cross-flow membrane filtration units have been specifically designed to deliver a clear, colorless, tasteless and aroma-free neutral alcoholic base. The neutral alcohol base used in a hard seltzer derives from a fermentation process with no distillation step.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.