Designed for high-stage or booster operation

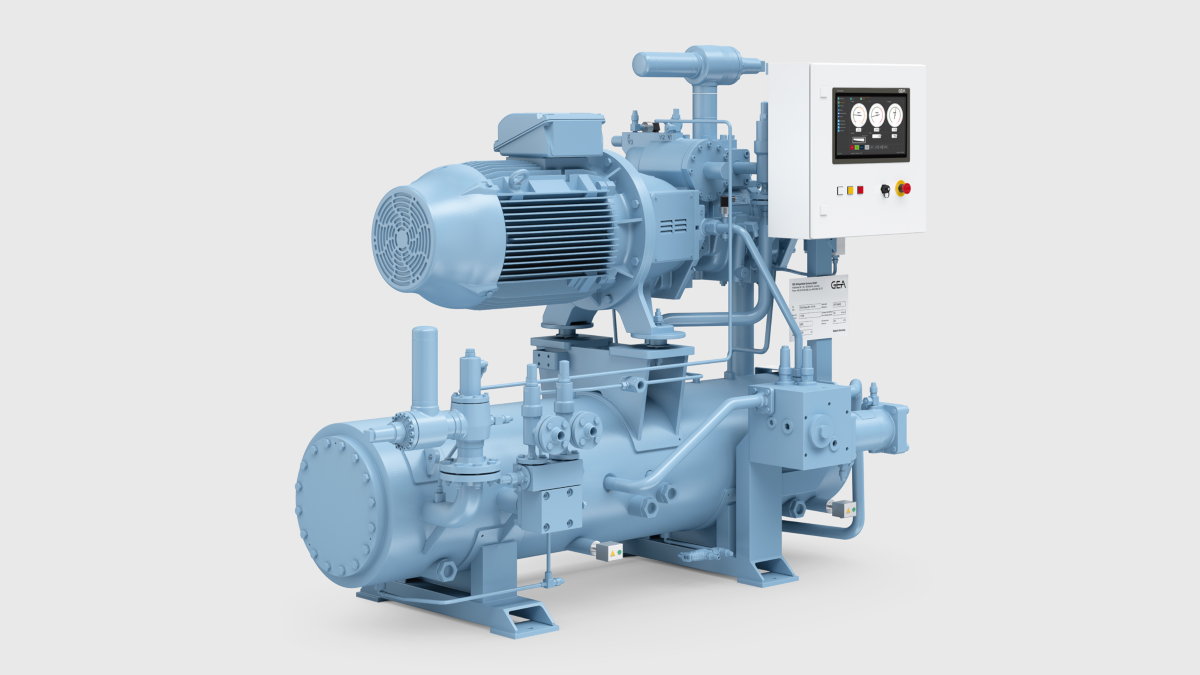

GEA FES GMX series

Designed for high stage, booster or single stage operation.

Package features:

- Service-friendly, compact layout.

- D-flange motor requiring no alignment.

- Multi-stage oil separator design guarantees low oil loss.

- Multiple oil-cooling options: thermosiphon, liquid-injection, water-cooled.

- Discharge hold back eliminating the need for external oil pump on most R-717 packages.

- High-definition, multi-touch GEA Omni control panel.

Learn more with GEA RTSelect – our product selection and configuration tool.

Webinar

Harmonizing for Efficiency — How GEA Equipment Works Together to Reduce Energy Costs (GEA North America)

Downloads

Related Products

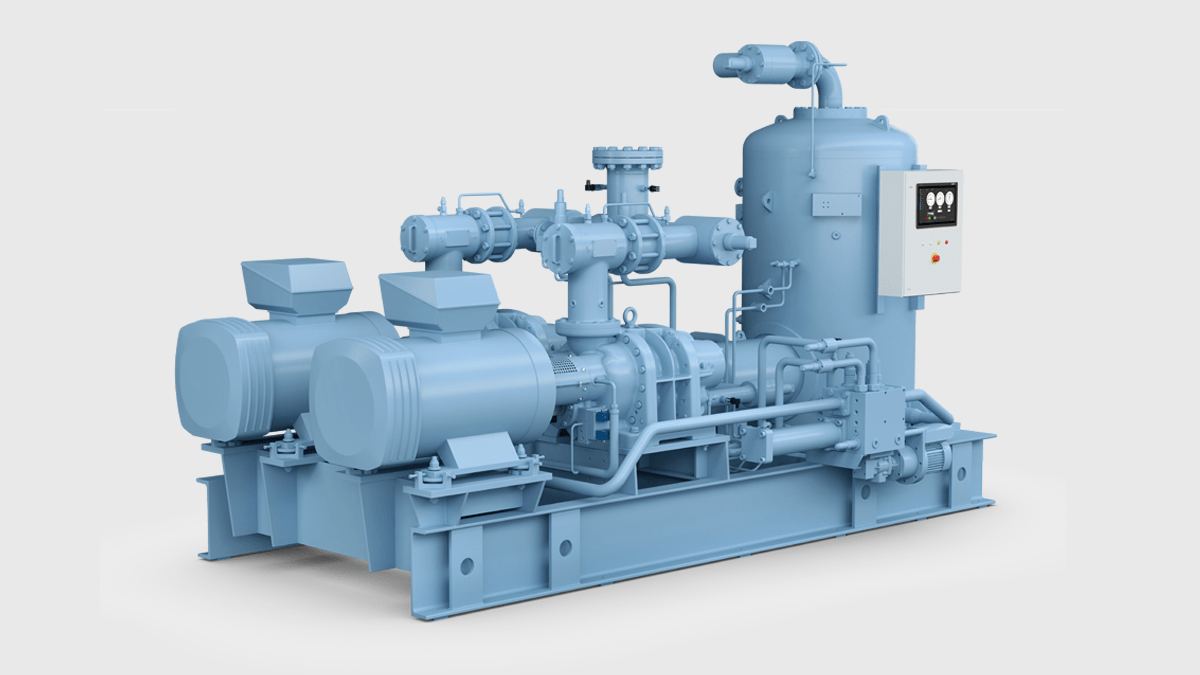

GEA FES GLX series

The GEA FES XSeries compressor package.

GEA Grasso M packages

Total Cost of Ownership redefinied - Your top choice for cost effectiveness over the entire product lifetime.

GEA Grasso SP2

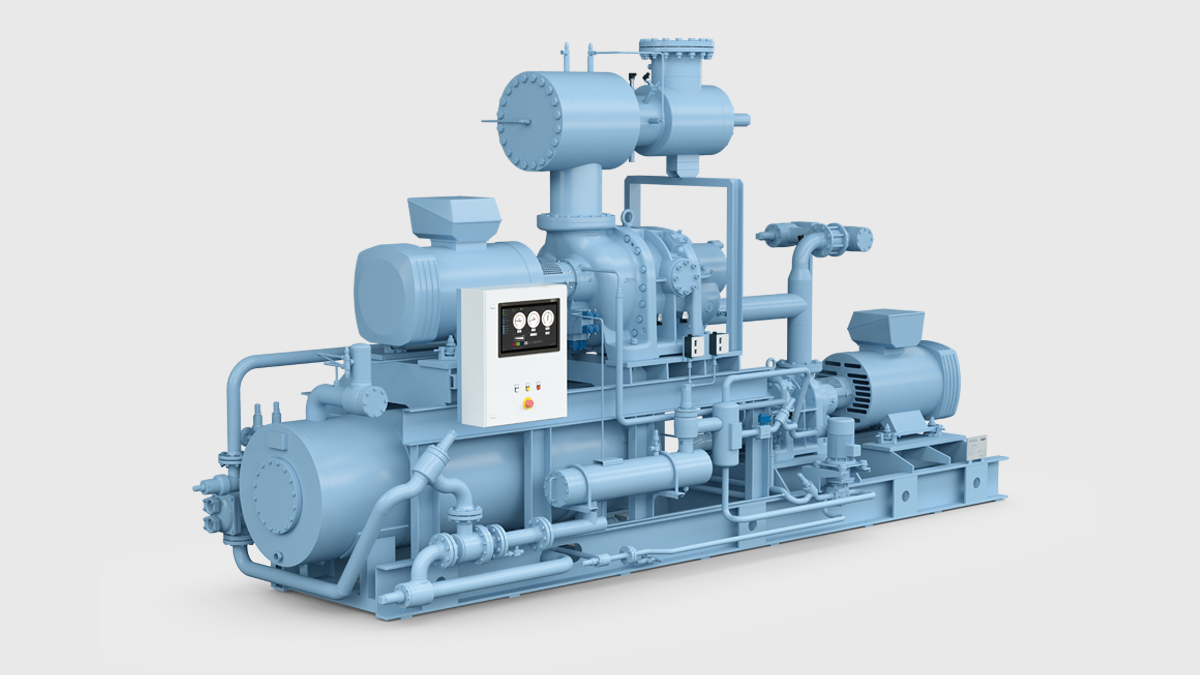

The high performer - GEA two-stage screw packages.

GEA Grasso SPduo

Best efficiency with all loads - GEA screw packages with two parallel-mounted compressors.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.