Pasta, Snacks & Breakfast Cereals Systems

GEA offers the widest range of solutions to produce all types of fresh and dry pasta, noodles, ramen, couscous, extruded breakfast cereals and snacks.

We provide dies, cutting systems, die washing equipment, packaging lines for pasta, baked goods and snacks. Thanks to this integrated and highly specialized supply chain, joining technology, flexibility and reliability, GEA can provide its outstanding engineering services, all tailor-made to our clients’ requirements. We offer turnkey production lines which cover the processing of raw materials into finished products, ensuring high quality results in terms of pasta, snacks and breakfast cereals.

Products

Showing 4 of 56

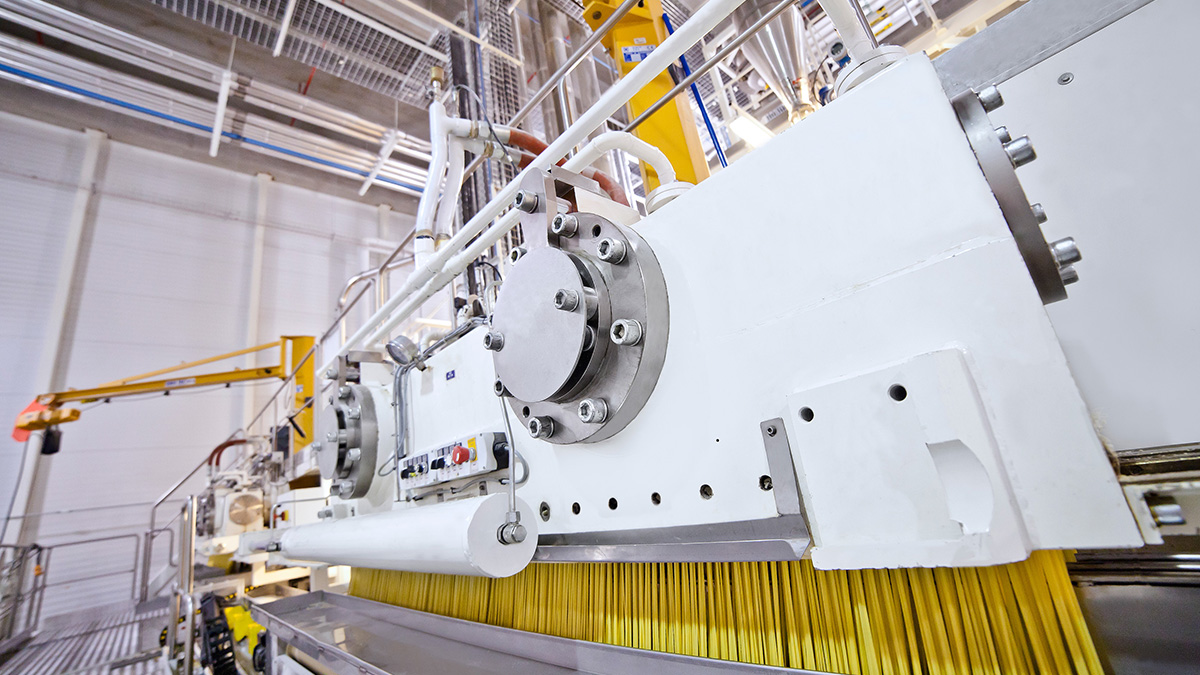

CA - Drying Zone

Machine designed to dry the product on the surface.

CF - Water cooker

Machine composed of a conveying belt that brings product inside a cooking tank containing heated water, with the possibility to regulate it. Used to cook and increase product humidity.

Cous cous - Production line

The technological capacity of GEA machinery to industrialize a process that has artisanal traditions that go back a century is most effectively shown in the cous cous line.

CV - Water cooker

Machine composed of a conveying belt that brings product inside a cooking tank containing heated water, with the possibility to regulate it. Used to cook and increase product humidity.

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.