GEA Hilge DURIETTA

Compact, Single- and Multi-Stage Centrifugal Pumps for Standard Applications

The Solid Pump for Applications in the Food and Beverage Industries

The GEA Hilge DURIETTA is designed in compliance with food technology requirements, making it ideal for jobs where hygiene is a key concern. For example, it is CIP- and SIP-capable with the performance characteristics outlined for pumps in DIN 12462. The unique hygienic design and the deep-drawn, rolled stainless steel AISI 316L make the GEA Hilge DURIETTA pump range suitable for:

Food & Beverage

- Microbreweries and dairies

- Bottling systems

- Food processing plants

- Drinking water systems

- CIP systems

Pharmaceutical and Related Industry

- Personal care industries

- CIP systems

Other Industrial Applications

- Semi-conductor manufacturing

- Heat exchangers

Mechanical Shaft Seal

GEA Hilge offers various seal arrangements:

- Single mechanical seal

- Double mechanical seal (tandem)

The standard mechanical shaft seal has an optimum position in the pump housing. This ensures lubrication, cleaning and cooling of the mechanical seal in accordance with the criteria of hygienic design.

Connections

GEA Hilge offers threads to DIN 11851 as standard for GEA Hilge DURIETTA pumps.

- Threads SMS

- Threads DIN 11864-1

- Flanges EN 1092-1 (DIN 2642)

- Flanges DIN 11864-2

- Clamps TRI-CLAMP

Other connections are available on request.

Impeller

The GEA Hilge DURIETTA has semi-open impellers, which allows easy and sufficient cleaning.

The GEA Smartpump Line for your Standard Applications

The GEA Hilge DURIETTA pump in the GEA Smartpump linie is the right choice for your applications under hygienic conditions. The range of these single- and multi-stage sanitary pumps allows you to choose between several standard variants to suit your task.

Design variants

Design variants - GEA Hilge DURIETTA| Standard variants | Description |

| GEA Hilge DURIETTA K | Horizontal installation, closed-coupled pump with plug-in shaft |

| GEA Hilge DURIETTA K-SUPER | Horizontal installation, motor with stainless steel shroud on stainless steel foot, closed-coupled pump with plug-in shaft |

GEA Hilge DURIETTA K Super

Technical data

Technical data| GEA Hilge DURIETTA | 50 Hz | 60 Hz |

| Flow | 8 m³/h | 8 m³/h |

| Head | 75 m | 42 m |

| Operating temperature | 95 °C | |

| Operating pressure | max. 8 bar | |

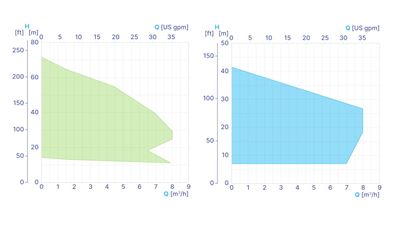

Performance curves

Downloads

Related Videos

The Pulse of Bodenheim - The global Center of Competence for Hygienic Pumps

The Pulse of Global Manufacturing

The Pulse of Koszalin - Hygienic Pumps Customer Event in the Factory of the Future

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.