Designed for a batch size of 40 hl (35 U.S. bbl)

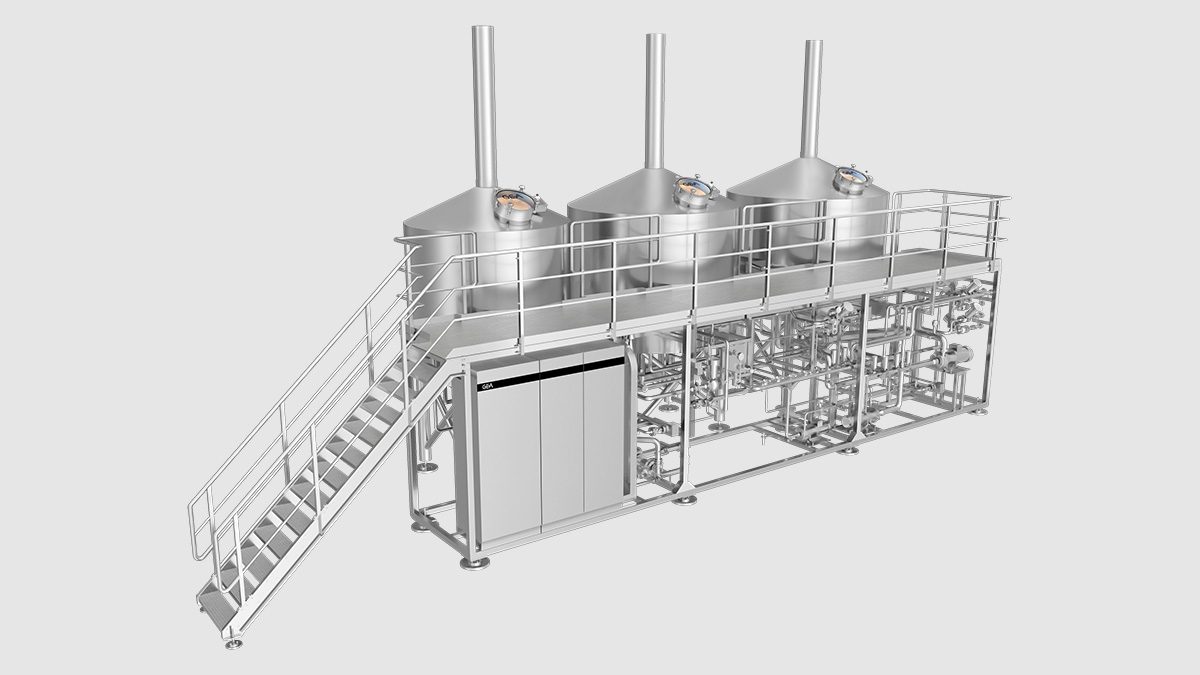

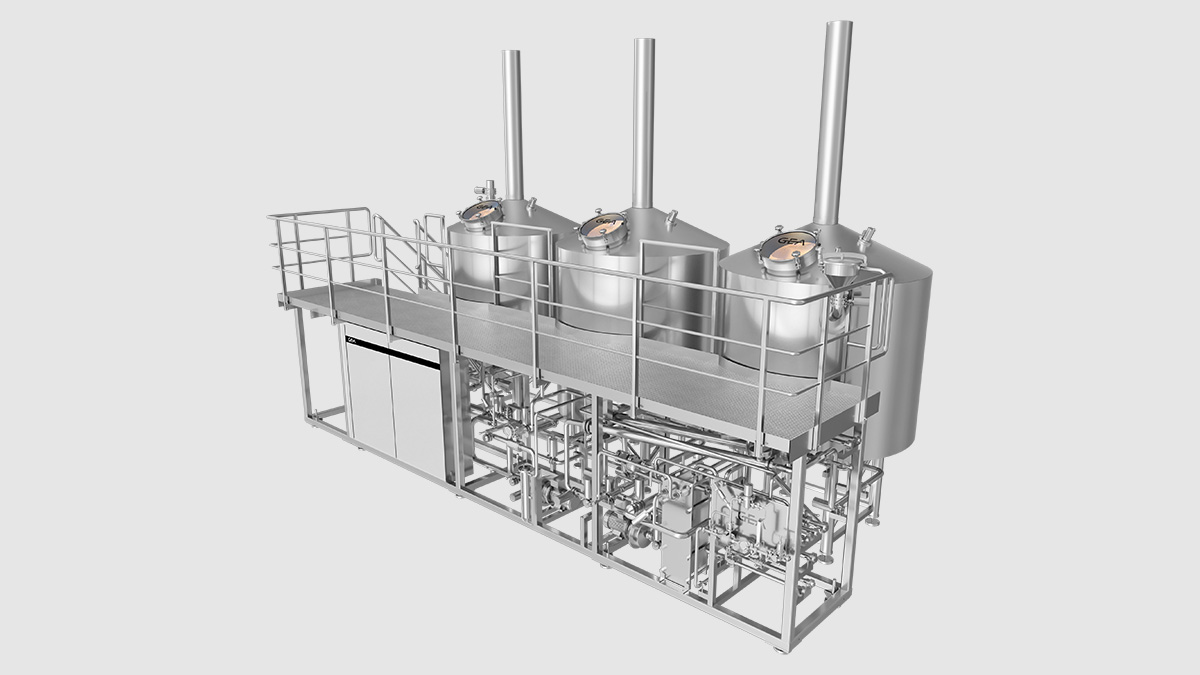

GEA CRAFT-STAR® Brewhouse XL

Skidded CRAFT-STAR® for medium-sized craft breweries with a cast-out quantity of 40 hl (35 US bbl).

With a striking visual appearance and a clear focus on specialty beer recipes, the CRAFT-STAR® XL is the right tool for the mid-sized craft brewer wishing to produce 40 hl of the finest wort in any style.

GEA´s state-of-the art brewing technologies gives you unsurpassed efficiency in the use of raw materials. And, thanks to the all stainless steel design, reliable components and solid craftsmanship, this sturdy workhorse brewery will serve you for many, many years.

Key benefits of the CRAFT-STAR® XL craft brewhouse

- Pre-engineered brewhouse concept is cost-effective and offers short lead times

- Versatile, over-sized vessels can handle high gravity beer recipes

- Easy to install and set up

- Flanged connections to utilities make for easy on site tie-ins

- External wort boiling allows for maximum batch size flexibility

- Highly efficient: up to 98% extract yield in the lauter tun

- Up to 5 or 7 brews within 24 hours means high throughputs, even in a one-shift operation

- Compatible with infusion and decoction mashing regimes

Fully equipped for every application

Compact and easy to ship, the CRAFT-STAR® XL complies with highest safety standards. Integrated systems monitor the differential pressure and provide full control of the lautering process, and the automated GEARBOXX® ensures repeatable batch production, process visualization and remote support. Further design elements include

- a grist hydrator and mash agitator

- a trub dam to handle high hop loads

- a central media interface and water mixer

- a built-in CIP manifold for semi-automated cleaning.

Available configurations and batch sizes

- Sized for 40 hl (35 US bbl) hot cast-out wort volume

- Choice of 2-, 3- and 4-vessel brewhouse configuration

- Toolbox includes mash tun kettle, lauter tun, mash/lauter tun, kettle/whirlpool and an extra whirlpool

- Can be upgraded with GEA MILLSTAR® wet milling technology for maximum plant performance

- Various add-ons available: vapor condenser, dosing equipment, spent grain handling, wort cooling/aeration, water supply skids, etc.

- Choice of attractive polished or matte vessel surface finishes

Downloads

Related Products

GEA CRAFT-STAR® Craft Brewhouse M

Skidded CRAFT-STAR® for smaller craft breweries with a cast-out quantity of 20 hl (17 US bbl).

GEA COMPACT-STAR® Craft Brewhouse

Modular COMPACT-STAR® for medium-sized and larger craft breweries with a cast-out quantity of 40-115 hl (35-100 US bbl)

GEA WORTSTAR Craft Wort Aeration

The semi-automatic wort aeration system for craft brewing solutions − DN 25 up to DN 50.

GEA MILLSTAR® Milling System

Our MILLSTAR® combines the advantages and benefits of conventional wet and dry milling. This method ensures almost perfect husk conservation and optimal grinding of the endosperm, which provides numerous advantages for your brewing process and your final product beer.

Service Products

GEA SAFEXPERT®

The innovative process diagnostic and consultant service.

GEA InsightPartner Brewery

GEA InsightPartner Brewery is a GEA digital service that provides a unique insight into your brewery’s performance in productivity, quality and sustainability through intelligent GEA software and GEA consultancy services.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.