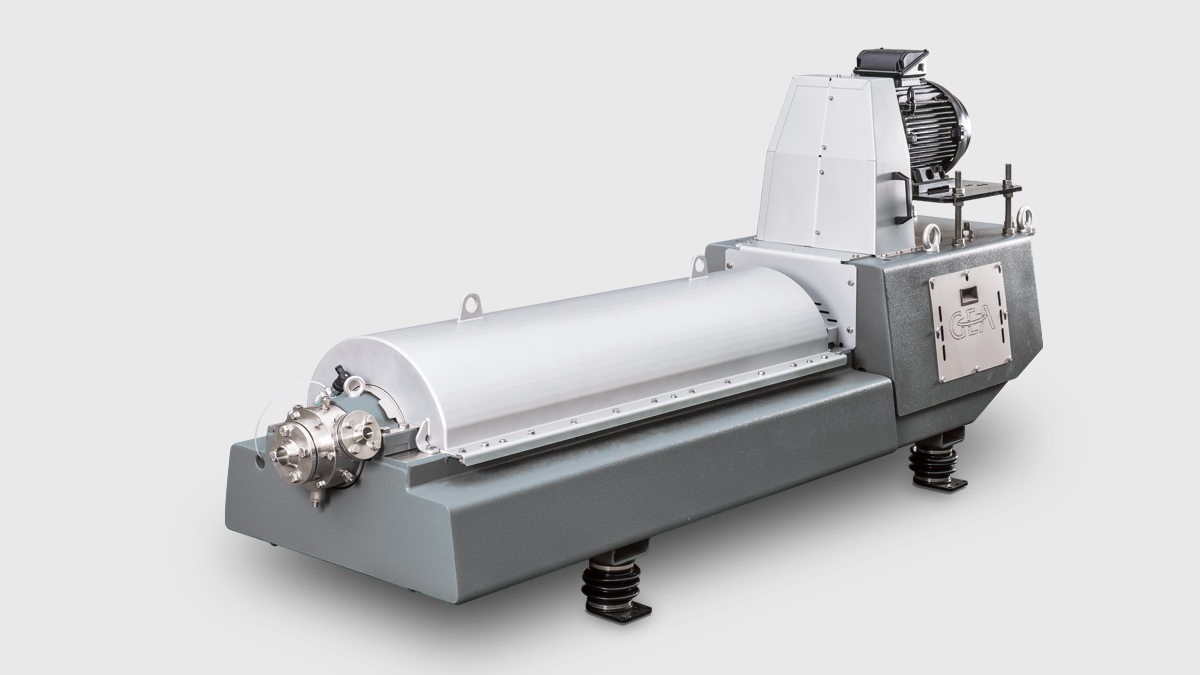

Separators for Oil Recovery

Polishing separators from GEA ensure the required premium quality of olive, palm, avocado and many other recovered vegetable oils by removing all residues while handling the product with extreme care

Once again, GEA equipment is state of the art here. The self-cleaning models reduce downtime and maintenance costs to a minimum, while handling the oil with the utmost care. The GEA hydrostop system ensures optimum product yield. With this system, the partial discharges can be adjusted so precisely that the liquid is retained in the bowl when solids are ejected, thus avoiding product losses.

Features & Benefits

- GEA hydrostop system for higher product yield

- Self-cleaning bowl for fully automatic operation

- Improved clutch design – for a longer wear lifespan

- All components which come into contact with product are made of stainless steel

- Flat-belt drive for low maintenance

- Highest g-force for highest oil yields

- Automated operation

- Continuous processing mode

- Simple maintenance

- Low-noise design

Downloads

Related Products

Nozzle Separators for Oil Recovery

Nozzle separators are used in the conventional process with vertical clarifiers in palm oil mills. GEA also offers special nozzle separators to the palm oil industry in order to recover oil from sterilizer condensate.

3-Phase Separating Decanters for Oil Recovery

For the recovery of olive, palm and other vegetable crude oil the decanter is always the heart of the installation. 3-Phase decanters separate both, the olive pulp or the palm oil sludge into oil, water and solids.

2-Phase Separating Decanters for Oil Recovery

The big advantage of the 2-phase separating decanter for olive and palm oil recovery is the enormous savings when it comes to dilution water.

Automation & Controls Separation

Even the best centrifuges cannot function optimally if they are not partnered with control systems of equal quality. For their range of separators and decanters, GEA offers standardized as well as tailor-made solutions for machine automation with many features to meet customer requirements.

Service Products

International Repair Network for GEA Centrifuges

Corrective repairs for your GEA separators and decanters

Remote FATs for GEA Centrifuges

Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time?

Here, too, we are at your side with the professional quality you are accu...

GEA EffiClean

EffiClean disk cleaning for centrifuges in mineral oil applications

Related Videos

Direct drive. Direct Impact. Separators with exchangeable direct drives.

Let’s get connected – digital solutions for GEA centrifuges

Let’s get connected – digital solutions for GEA separators and decanters

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.