Overview

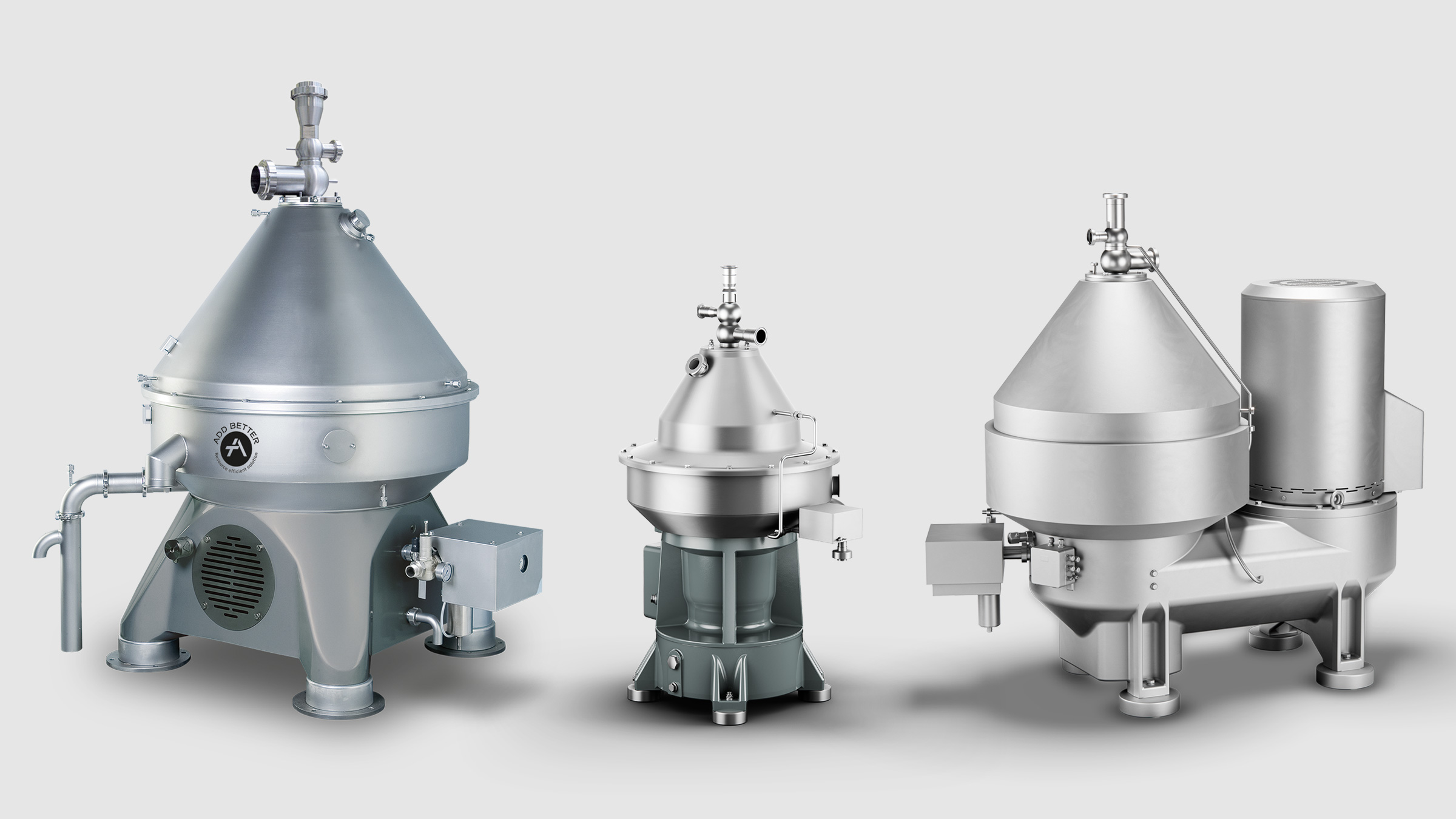

Solid-Wall Bowl Separators for Milk & Whey

This belt-driven solid-wall bowl separator has been designed for milk or whey skimming and milk standardizing.

Standard scope of supply

Commissioning spare parts

Lubricants and gaskets for commissioning

- Set of bowl top gaskets

- Flat belt

- Initial filling of lubrication oil

Special tools

Set of special tools for dismantling and assembling of the machine.

Optional

Base frame

Base frame, mild steel, varnished to be integrated in the floor structure.

Spare parts

- Set of spare parts for discharge housing, hood and bowl

- Set of spare parts for drive

Optional

Valves

Set of manual valves and indicating instruments for the adjustment of feed, skim milk discharge pressure and cream flow as well as the continuous standardizing of milk and cream fat content. Milk cleaning (complete re-blending) and full skimming are possible as well.

Control system

Manual motor starter

Capacity

Skimming: 600 l/h - 10,000 l/h

Standardizing: 600 l/h - 12,500 l/h

Downloads

Related Products

Automation & Controls Separation

Even the best centrifuges cannot function optimally if they are not partnered with control systems of equal quality. For their range of separators and decanters, GEA offers standardized as well as tailor-made solutions for machine automation with many features to meet customer requirements.

Clarifiers for Milk, Whey and Calcium Phosphate

GEA clarifiers are used in the dairy industry to improve quality.

Separators for Milk and Whey Skimming

GEA offers a comprehensive centrifuge portfolio for the skimming and standardization of milk and whey from various farm animals.

Service Products

International Repair Network for GEA Centrifuges

Corrective repairs for your GEA separators and decanters

Remote FATs for GEA Centrifuges

Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time?

Here, too, we are at your side with the professional quality you are accu...

Related Videos

Stay stronger with GEA Service Level Agreements

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.