GEA Service ‒ Keeping it running

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Purger

The GEA Purger starts automatically when the concentration of these non-condensable gases exceeds 2 %, and stops when the concentration drops to below 1 %.

The purger operates independently from the main refrigeration system and is suitable for in- as well as outdoor installation. It comprises an integrated, low temperature refrigeration cycle, including a hermetic compressor and an air-cooled condenser, using the environmentally-friendly natural refrigerant R290 (propane).

Your benefits

- Energy-efficiency: Maximum energy-efficiency with minimum power consumption

- Environmentally-friendly: Operates with the environmentally-friendly natural refrigerant R290 (propane)

- Simple plug & play: Plug and play for in- and outdoor use

- Quality: Blow-off valve with calibrated orifice for highest quality, rather than quantity purging

| Technical specifications | |

| Refrigerant: | R290 (propane) |

| Refrigerant charge: | 150 g |

| Dimensions (LxWxH): | 700 x 330 x 450 mm |

| Weight: | approx. 50 kg |

| Protection: | IP44 |

| Power supply: | 230V @ 50 Hz |

| Connection power: | 400 Watt |

| Design: | According to CE PED |

| Connections: | Flange connection for 22/27 mm |

| Ambient temperature: | -15 to +45 °C |

Learn more with GEA RTSelect – our product selection and configuration tool.

Downloads

Related Products

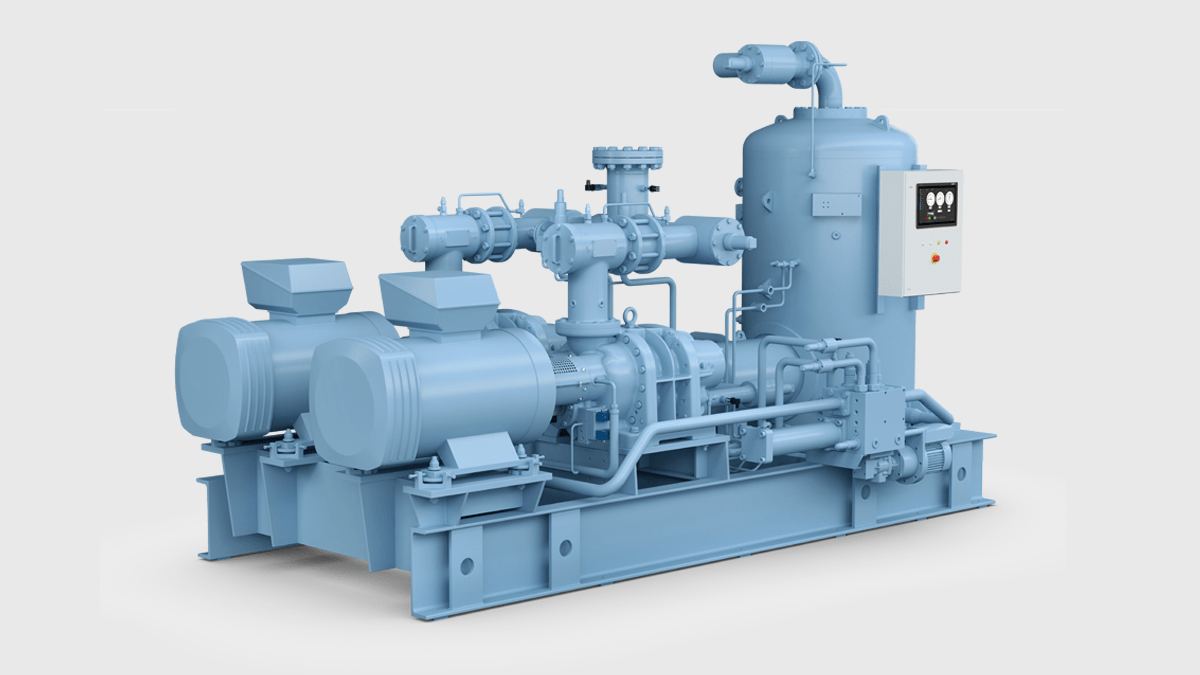

GEA Grasso SPduo

Best efficiency with all loads - GEA screw packages with two parallel-mounted compressors.

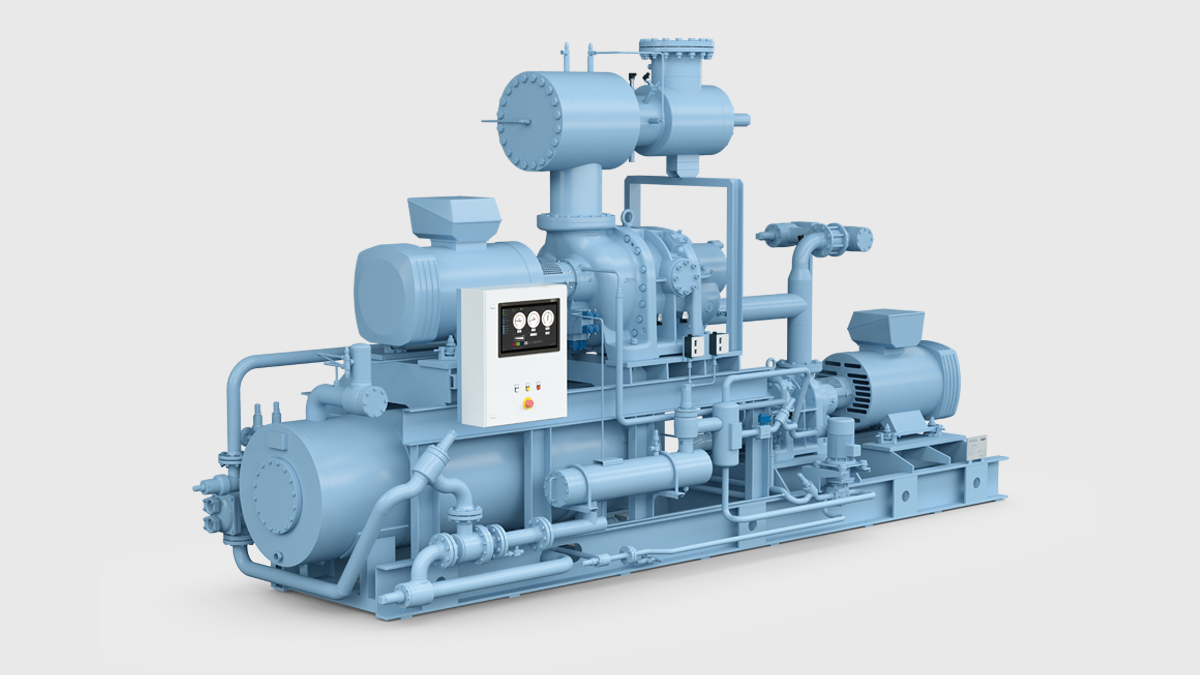

GEA Grasso SP2

The high performer - GEA two-stage screw packages.

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

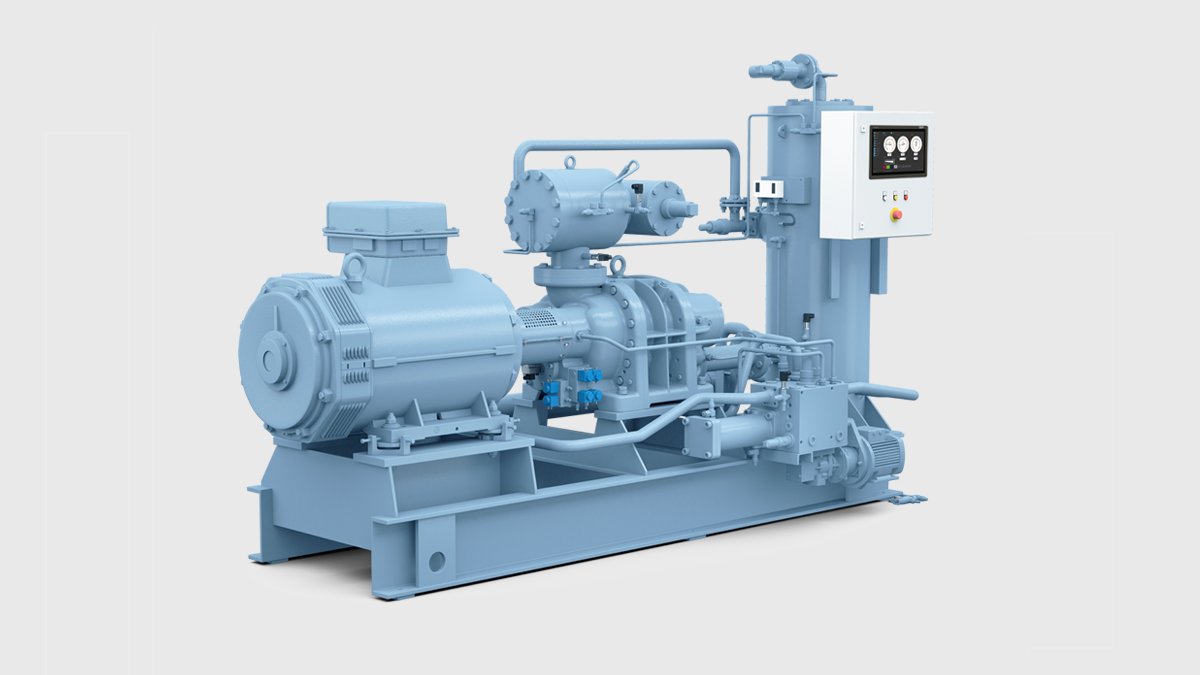

GEA Grasso SP1

Efficient. Reliable. Versatile. - GEA single-stage screw packages.

Service Products

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Compressor Conversion Kit (GCCK)

Update your existing screw compressor packages

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.