Digital solution for heating and refrigeration plants

GEA InsightPartner Blu-Red Care

GEA InsightPartner Blu-Red Care is our digital solution for heating and refrigeration plants to increase your machine availability and safety. It takes full responsibility by making use of your operating machine data as well as GEA’s expertise on refrigeration systems and processes. Your tool for equipment safety and availability.

GEA Blu-Red Care addresses daily pain points as it increases the transparency on machine operation, provides relevant data to pre-clarify or even avoid annunciations as well as pro-actively notify you about upcoming problems based on trends of data. The GEA Cloud® is the basis for all digital solutions that support our customers. Analyze your machine data securely, ISO 27001 certified environment to unlock new services and increase production.

Connect now!

Features:

Key Insights.

Present all the relevant data at a glance, saving you valuable time and effort. Say goodbye to costly machine breakdowns and hello to continuous operations.

Fault Analysis & System Health Dashboard.

Notifying you about upcoming faults and system health errors of the machine and providing you with a comprehensive overview of those issues so you don’t miss any serious incident.

Troubleshooting.

Provides you relevant operating machine data based on your specific fault situation, supporting you in how to deep dive and solve the faults as quickly and efficient as possible.

Your benefits:

Easy to use.

We've designed GEA InsightPartner Blu-Red Care to be intuitive and easy to understand.

Transparency.

Machine usage transparency allows you to take a proactive approach to equipment management and ensure the reliability and longevity of your assets.

Optimize uptime & performance.

GEA Blu-Red Care helps you optimize equipment uptime and performance with actionable insights.

Focus on Core business.

GEA Blu-Red Care takes care about your refrigeration system, letting you focus on your core business. Stressful troubleshooting and time-consuming fault analyses are part of the past.

Please contact your local GEA office for additional information.

Downloads

Related Products

GEA Omni Control Panel

The intuitive touch for machine control technology.

GEA Omni Control Panel for Complete System Control

The GEA Omni control panel is customizable for complete system control — an all-inclusive command center that controls the entire refrigeration system from one panel.

GEA Grasso Maintenance Monitor (GMM)

First class electronic monitoring based on proven developments.

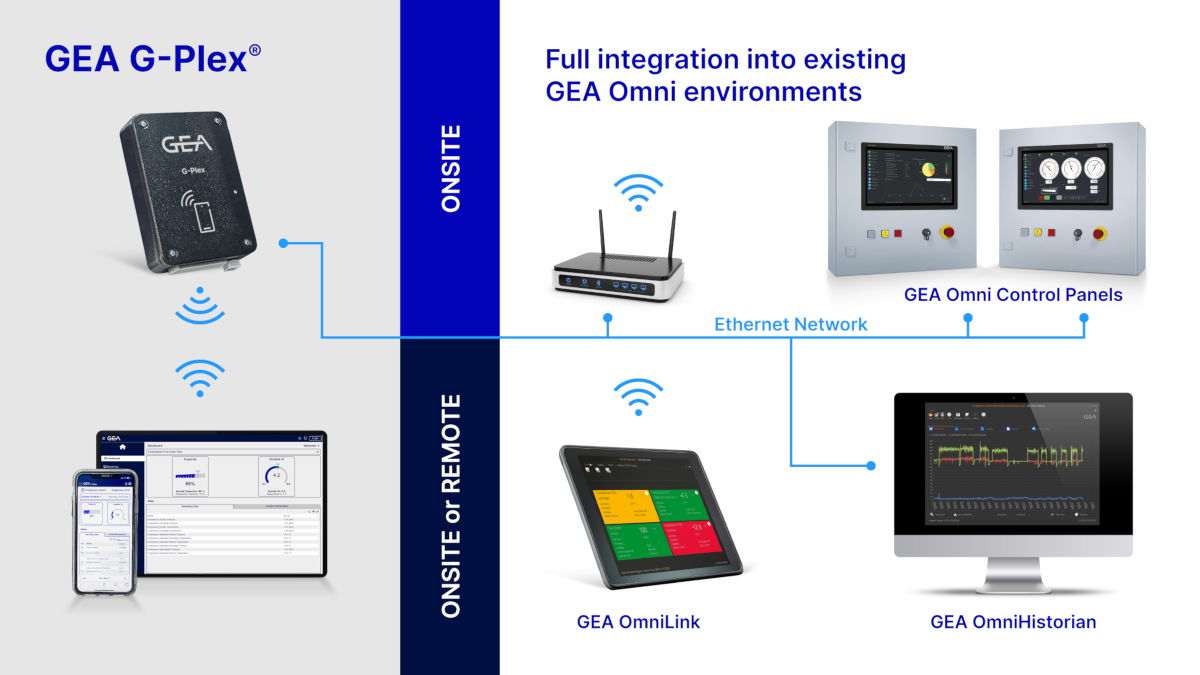

GEA G-Plex®

Now available for Vi control, condition monitoring and more for GEA Grasso screw compressors

Service Products

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Compressor Conversion Kit (GCCK)

Update your existing screw compressor packages

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.