Centrifuge

Nozzle Separators for Strained Yoghurt, Quark and Fresh Cheeses

Whether quark, fresh cheese, labneh, skimmed milk yoghurt or Greek yoghurt – the demand on the global milk market is multi-faceted. As a major market player with decades of experience for these applications, GEA has designed both specific equipment and production processes such as the Thermo Quark process for the individual products and established them in practice. With our focus on the continued improvement and development of machines and process lines, we ensure that fresh cheese and yoghurt production is efficient,economical and sustainable.

A product’s successis based firstly on its exceptional quality, here: a “natural” flavor and a creamy and smooth “mouthfeel”. Compared to traditional manual and time-intensive methods,whey is today separated with the aid of GEA centrifuges at 10,000 times the force of gravity in order to obtain the desired product – with a quality and taste that equals the original in its full-bodied creaminess.

Customer benefits

Depending on the individual process, our centrifuges offer decisive advantages, for example compared with the membrane filtration process:

- Constant flow rate

- Constant product characteristics (e.g. with respect to texture or total solids)

- Option of direct filling after concentration

- Easy integration into existing process line

- Quick and easy adaptation of total solids

- Option of integration into an existing CIP line

- Long operating times (minimum 16 hours) compared with alternative processes

- No addition of stabilizers and powders required

Highly efficient and flexible production

GEA nozzle separators are used in the production of

- Quark (standard or Thermo Quark process, from buttermilk, from recombined milk)

- Fresh cheese

- Strained yoghurt (Labaneh)

- Labneh

- Greek yoghurt

- Skyr

Machine Portfolio

Machine Portfolio

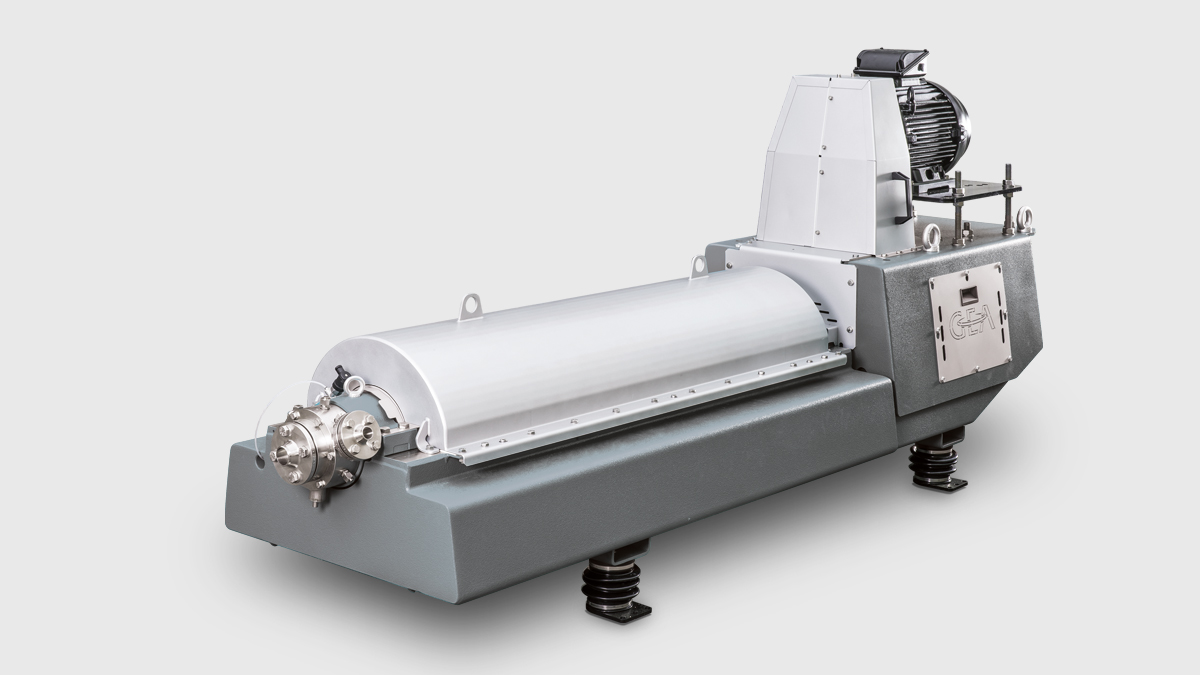

Nozzle Separator KDB KDE Cheese Yoghurt

The product is fed into the machine via a closed system. The whey is discharged under pressure via a centripetal pump and the fresh cheese is released via the nozzles to a solids catcher and floats further down to the cheese hopper.

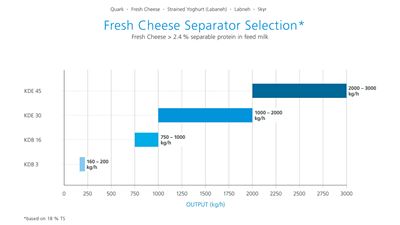

Fresh Cheese Separator Selection

Featured

Fresh cheese uncovered with GEA separation technology

Downloads

Related Products

Separators for Double Cream Fresh Cheese

For the production of double cream fresh cheese from fat milk of 8 to 12 percent fat content. Driven by a frequency-controlled 3-phase AC motor without clutch via a flat belt.

Clarifying Decanters for Cheese Curd, Casein and Lactose

GEA decanters offer numerous advantages across a wide range of applications which make possible a highly efficient and reliable process management.

Automation & Controls Separation

Even the best centrifuges cannot function optimally if they are not partnered with control systems of equal quality. For their range of separators and decanters, GEA offers standardized as well as tailor-made solutions for machine automation with many features to meet customer requirements.

Service Products

International Repair Network for GEA Centrifuges

Corrective repairs for your GEA separators and decanters

Remote FATs for GEA Centrifuges

Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time?

Here, too, we are at your side with the professional quality you are accu...

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.