Efficiency at its most flexible

GEA BluGenium

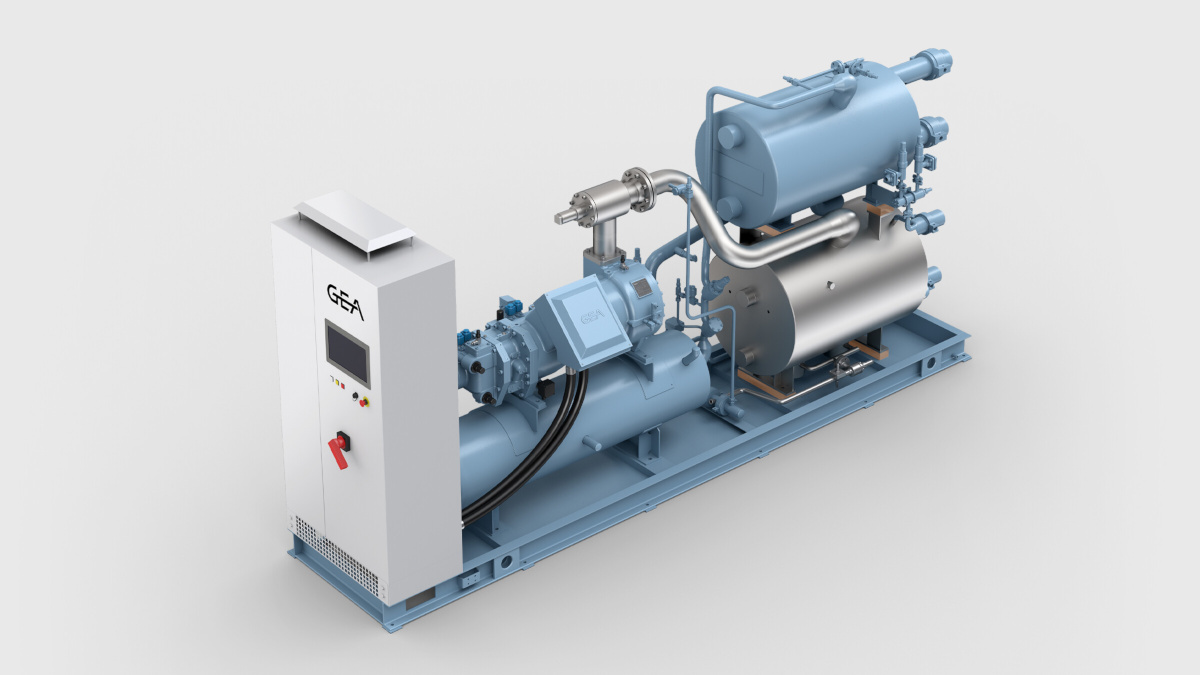

The GEA BluGenium chiller, equipped with a reciprocating compressor and powered by natural refrigerant ammonia, arrives fully piped and wired for immediate setup. Engineered for maximum energy efficiency, it excels under full and partial loads, making it the essential choice for your cooling needs. CE certified.

GEA has used its many years of engineering experience in the development of the GEA BluGenium ammonia chiller for indoor installation. This has resulted in outstanding energy efficiency that reduces the Total Cost of Ownership (TCO) to a minimum. The extended series now covers seven model sizes, increasing the available capacity range by almost 60%.

GEA BluGenium is the first choice for market-leading efficiency even with high part-load operation.

Optimized Efficiency for Every Load

GEA BluGenium is flexible and energy efficient, whether your refrigeration plant operates at full-load or part-load. With a European Seasonal Energy Efficiency Ratio (ESEER) above 9, the models offer maximum energy-efficiency, with minimum energy consumption and cost, under all load conditions.

Highlights & Technical Features

- Compact reciprocating chiller

- Excellent part-load efficiency, ESEER above 9

- Fulfils EcoDesign requirements

- Future-proof with natural refrigerant ammonia (R717) – in accordance with the F-gas regulations, the initiative for the prohibition of F-gases.

- 310 – 2,040 kW full-load cooling capacity R717, 12 / 6°C

- Secondary refrigerant outlet temperature -15 to +15°C

With the two reciprocating compressors GEA Grasso V1400 and V1800 now available with the BluGenium, this series delivers about 60% more cooling capacity than before.

| Type | Cooling capacity (kW)

R717, 12 / 6°C |

EER | Dimensions (mm) | Weight

(kg) |

||

| L | W | H | ||||

| GEA BluGenium 300 | 310 | 5.9 | 4600 | 1400 | 2250 | 5700 |

| GEA BluGenium 450 | 460 | 5.9 | 5000 | 1400 | 2250 | 6100 |

| GEA BluGenium 600 | 615 | 6.0 | 5600 | 1400 | 2250 | 7600 |

| GEA BluGenium 900 | 860 | 6.0 | 5600 | 1400 | 2300 | 8100 |

| GEA BluGenium 1200 | 1290 | 5.9 | 6000 | 1400 | 2300 | 9700 |

| GEA BluGenium 1400 | 1665 | 5.7 | 6800 | 1400 | 2300 | 11100 |

| GEA BluGenium 1800 | 2040 | 5.6 | 7800 | 1400 | 2300 | 12500 |

Learn more about sustainable and efficient industrial refrigeration and dive into the world of chillers

Looking for the perfect chiller to suit your refrigeration needs?

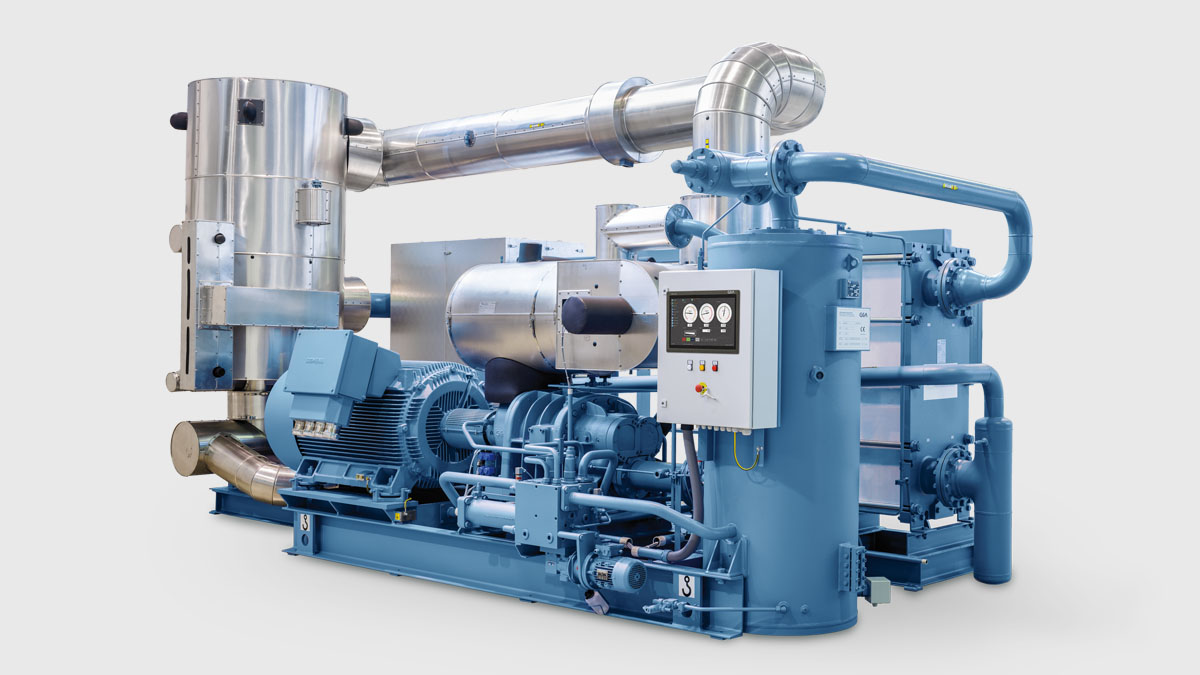

The heart of the GEA BluGenium chiller is the V series reciprocating compressor.

The V Series reciprocating compressors are characterized by compact design, high reliability, high-quality components, ease of maintenance and minimal total cost of ownership due to low energy consumption.

The low specific power consumption is based on the structural characteristics of the reciprocating compressor. The design of the GEA Grasso V compressor enables low discharge temperatures and a small pressure drop that enhance system efficiency.

Our reciprocating compressors are manufactured in 's-Hertogenbosch, Netherlands. We invite you to visit and see the precision and quality of our production process first-hand.

GEA chooses natural refrigerants

Downloads

Related Products

GEA BluAstrum

GEA BluAstrum provides an econonimcal entry into the GEA Blu chiller series, without compromises regarding the technological concept.

CE certified.

GEA BluX

GEA BluX is among the world‘s first ammonia chillers with a semi-hermetic compact screw compressor, developed as an environmentally friendly solution in line with the global trend towards a greener future through the use of natural refrigerants.

CE certified.

GEA BluAir

This product line enables employment of the GEA Blu chiller technology in outdoor applications.

CE certified.

GEA Grasso FX P / GEA Grasso FX Pduo

For applications with large temperature differences between evaporation and condensation GEAs screw compressor chillers FX P and FX Pduo are a modular solution.

CE certified.

Service Products

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Compressor Conversion Kit (GCCK)

Update your existing screw compressor packages

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.