The reliable and versatile range for cooling

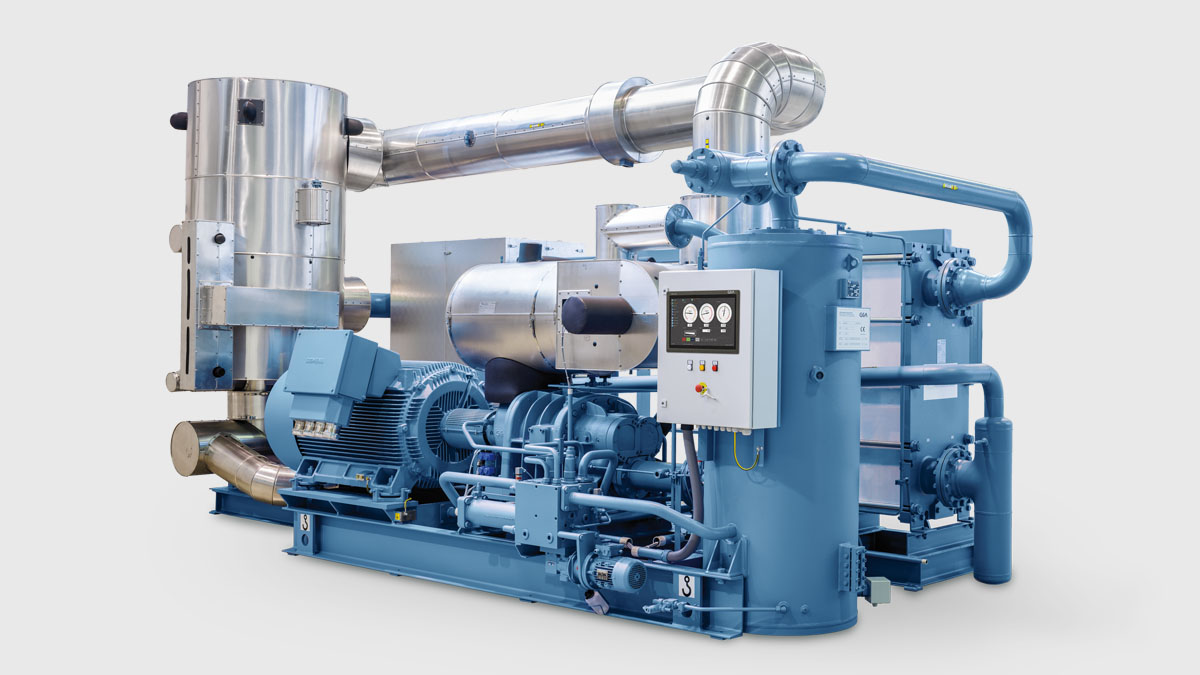

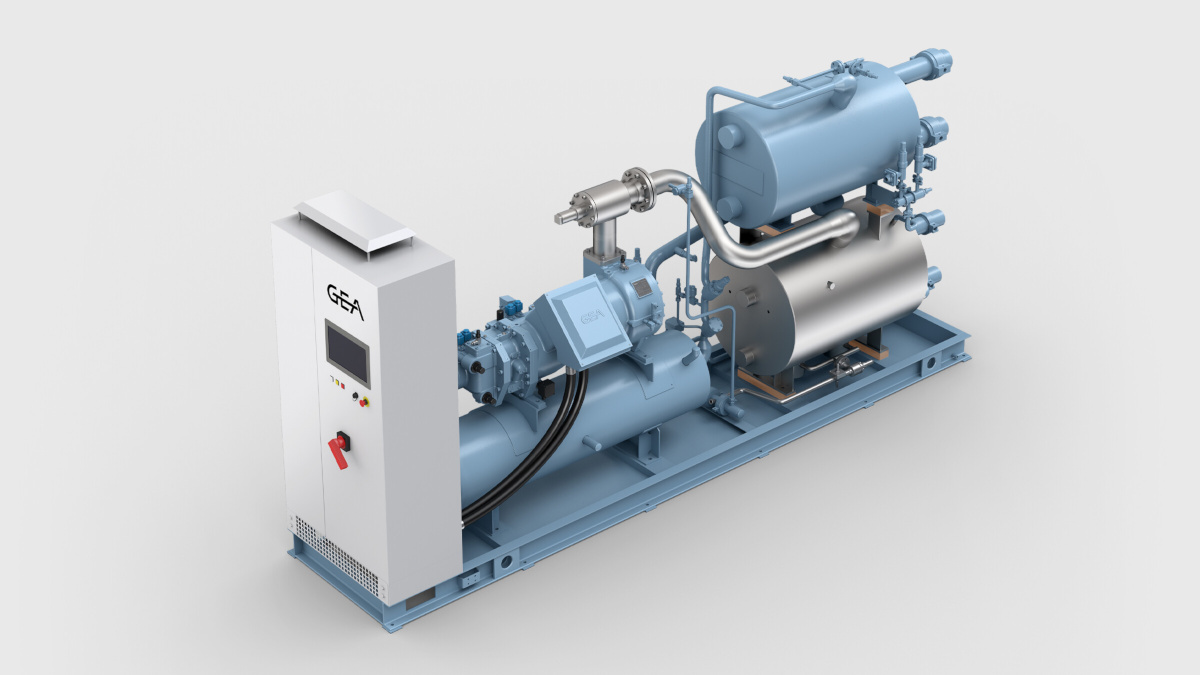

GEA Grasso FX P / GEA Grasso FX Pduo

This chiller series is the industrial standard for applications with great temperature difference between evaporation and condensation. CE certified.

Technical features

- Wide application range as chiller, heat pump (28bar), or alternating machine

- Flexible and modular design

- Stepless capacity control with capacity slide and frequency inverter

- Automatic and variable internal volume ratio (Vi)

- High-efficiency plate heat exchangers as evaporators and condensers

- Liquid cooled condenser by default, suitable for other condenser types

- Screw compressor chillers with 1 or 2 compressors (FX P or FX Pduo)

- Low discharge temperatures even at high pressure ratios

- Economizers as option

Learn more with GEA RTSelect – our product selection and configuration tool.

| Type | Compressor | Capacity¹) (kW) | Dimensions (mm) | Weight (kg) | |||

| L | W | H | |||||

GEA Grasso FX P(1 compressor) | 200 | GEA Grasso SH-C | 209 | 2100 | 1700 | 2200 | 3200 |

| 250 | GEA Grasso SH-D | 245 | 2100 | 1700 | 2200 | 3250 | |

| 300 | GEA Grasso SH-E | 294 | 2100 | 1700 | 2200 | 3350 | |

| 350 | GEA Grasso SH-G | 348 | 2100 | 1700 | 2200 | 3500 | |

| 450 | GEA Grasso MC-H | 445 | 3400 | 2000 | 2300 | 5200 | |

| 550 | GEA Grasso MC-L | 525 | 3400 | 2000 | 2300 | 5400 | |

| 650 | GEA Grasso MC-M | 646 | 3700 | 2100 | 2650 | 6800 | |

| 800 | GEA Grasso LT-P | 795 | 4000 | 2100 | 2650 | 7800 | |

| 900 | GEA Grasso MC-N | 855 | 3950 | 2200 | 2650 | 8100 | |

| 1100 | GEA Grasso LT-R | 1027 | 4200 | 2200 | 2650 | 9000 | |

| 1300 | GEA Grasso LT-S | 1274 | 4200 | 2200 | 2650 | 9600 | |

| 1500 | GEA Grasso LT-T | 1394 | 4200 | 2200 | 2650 | 10300 | |

| 1700 | GEA Grasso LT-V | 1647 | 4600 | 2500 | 2900 | 11000 | |

| 2000 | GEA Grasso LT-W | 1900 | 4800 | 2600 | 2900 | 12000 | |

| 2400 | GEA Grasso LT-Y | 2306 | 5000 | 2500 | 3650 | 12800 | |

| 2800 | GEA Grasso LT-Z | 2761 | 6500 | 2800 | 3650 | 14900 | |

| 3300 | GEA Grasso LT-XA | 3260 | 6700 | 3000 | 3650 | 16250 | |

| 4200 | GEA Grasso LT-XB | 4169 | 6500 | 4000 | 5000 | 25500 | |

| 5000 | GEA Grasso LT-XC | 4923 | 7000 | 4500 | 5000 | 27500 | |

| 5800 | GEA Grasso LT-XD | 5828 | 7500 | 4500 | 5000 | 30000 | |

| GEA Grasso FX Pduo (2 compressors) | 2x200 | 2 x GEA Grasso SH-C | 418 | 4500 | 2400 | 2300 | 4800 |

| 2x250 | 2 x GEA Grasso SH-D | 490 | 4500 | 2400 | 2300 | 4900 | |

| 2x300 | 2 x GEA Grasso SH-E | 588 | 4500 | 2400 | 2300 | 5180 | |

| 2x350 | 2 x GEA Grasso SH-G | 696 | 4500 | 2400 | 2300 | 5480 | |

| 2x450 | 2 x GEA Grasso MC-H | 890 | 5200 | 2500 | 2650 | 10000 | |

| 2x550 | 2 x GEA Grasso MC-L | 1050 | 5700 | 2750 | 2650 | 10600 | |

| 2x650 | 2 x GEA Grasso MC-M | 1292 | 6000 | 2750 | 2650 | 11150 | |

| 2x800 | 2 x GEA Grasso LT-P | 1590 | 6700 | 3200 | 2900 | 13500 | |

| 2x900 | 2 x GEA Grasso MC-N | 1710 | 6500 | 3200 | 2800 | 12200 | |

| 2x1100 | 2 x GEA Grasso LT-R | 2054 | 7300 | 3600 | 3600 | 14500 | |

| 2x1300 | 2 x GEA Grasso LT-S | 2548 | 7500 | 3600 | 3600 | 15500 | |

| 2x1500 | 2 x GEA Grasso LT-T | 2788 | 8100 | 3900 | 3600 | 17500 | |

| 2x1700 | 2 x GEA Grasso LT-V | 3294 | n.a. | n.a. | n.a. | n.a. | |

| 2x2000 | 2 x GEA Grasso LT-W | 3800 | n.a. | n.a. | n.a. | n.a. | |

| 2x2400 | 2 x GEA Grasso LT-Y | 4612 | n.a. | n.a. | n.a. | n.a. | |

¹) Secondary refrigerant temperature 12/6 °C, cooling medium temperature 27/32 °C

Munich opts for air conditioning with natural refrigerants

Downloads

Related Products

GEA BluGenium

With an ESEER >9, these models fully exploit the potential of the GEA Blu chiller concept.

CE certified.

GEA Blu-Red Fusion

The GEA Blu-Red Fusion is a combination of the successful GEA Blu chillers (low stage) and GEA Red heat pumps (high stage).

CE certified.

GEA BluX

GEA BluX is among the world‘s first ammonia chillers with a semi-hermetic compact screw compressor, developed as an environmentally friendly solution in line with the global trend towards a greener future through the use of natural refrigerants.

CE certified.

GEA BluAstrum

GEA BluAstrum provides an econonimcal entry into the GEA Blu chiller series, without compromises regarding the technological concept.

CE certified.

Service Products

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Compressor Conversion Kit (GCCK)

Update your existing screw compressor packages

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.