Heating & refrigeration

Heat pumps

Heat to cool - Using GEA heat pumps to cool our warming planet

Explore our products

Heat accounts for more than half of the global total final energy consumption, mostly produced from fossil fuels. If the ambitious targets set in the historic Paris Agreement are to be achieved, we need to accelerate heat decarbonization and create a better world for our future generations. In the drive for a carbon-neutral future, energy-efficient heat pumps are rapidly becoming the technology of choice. Using heat pumps to cool our warming planet makes a lot of sense.

Applications

Products

Showing 4 of 5

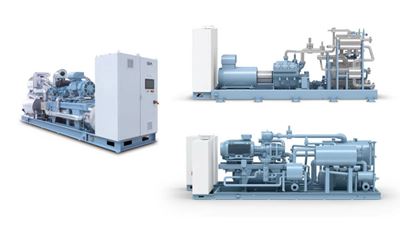

Customized GEA heat pumps

Customized heat pumps are designed for optimized efficiency and a wide range of temperatures and capacities. They serve all common industrial applications and district heating. They are applied when special conditions or requirements outstrip the limits of our standard heat pumps.

GEA Blu-Red Fusion

The GEA Blu-Red Fusion is a combination of the successful GEA Blu chillers (low stage) and GEA Red heat pumps (high stage).

CE certified.

GEA open type heat pumps

Open type GEA heat pumps are designed for the direct connection to a refrigeration plant. They use condenser heat as the heat source by efficiently recovering the heat with minimum pressure loss using a compact open intercooler. They can provide heat for any industrial process and are commonly used in food and dairy plants.

GEA RedAstrum

GEA RedAstrum is the standard ammonia screw compressor heat pump that meets the increasing demand for efficient heating. The series is known for its wide capacity and temperature range. It features high-end components and a sophisticated, compact design.

In industry and commerce, the requirements for heating and process heat are highly specific. Heat pumps can very often satisfy these needs. Thanks to their efficiency and short amortization period, they represent an environmentally friendly and economically attractive alternative to conventional heating systems. A heat pump raises heat from its surroundings – water, or waste process heat – from a lower temperature level to a higher.

Whatever application may interest your company for a heat pump, it will – when its overall life cycle is considered – amortize quickly by a reduction in energy consumption and emissions that affect the global climate. In addition, emphasis is placed on using natural refrigerants such as ammonia wherever possible.

Contact our heat pump experts

Webinar

GEA Heat pumps - Products and applications

4 reasons to choose heat pump technology

1. It lowers your energy consumption

Heat pump solutions, either combined with energy-efficient refrigeration systems, or stand alone can improve your heating performance significantly.

2. It decreases your operating costs

By replacing the fossil fuel based-heating system with a highly efficient heat pump, you will lower your operating costs.

3. It reduces your carbon footprint

By reducing or eliminating the use of fossil fuel, a heat pump can help you pave the way towards your zero-emission target.

4. It meets your sustainability goals

A heat pump solution is a future-proof investment, especially in the face of ever-stricter guidelines on carbon emissions and environmental compatibility.

Heat pump technology reduces industrial carbon output

Customer cases

Service Products

GEA Ammonia Dryer

The GEA Ammonia Dryer removes water from the refrigerant cycle and makes the perfect addition to ammonia refrigeration systems along with filters and purgers.

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Omni Retrofit Panel

The intuitive touch for screw and piston compressor control. powerful, yet approachable. Cerebral, yet intuitive. Sophisticated, yet simple. Simply – GEA Omni.

PR-OLEO® Premium-Quality Ammonia Refrigeration Oils

PR-OLEO® ammonia oils are the natural choice to optimize industrial cooling and heating applications operating with reciprocating or screw compressors.

GEA Service Kits for reciprocating compressors

Welcome to the world of simplicity with GEA Service Kits for reciprocating compressors. Our mission is clear - to make your experience with original spare parts seamless and your operations smoother than ever. "Take it easy, use a kit" is not just a tagline – it is a promise we deliver on.

GEA NEXUS - Holistic Engineering Solutions

Ammonia – Providing the right temperature for change

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.