Reciprocating Compressors

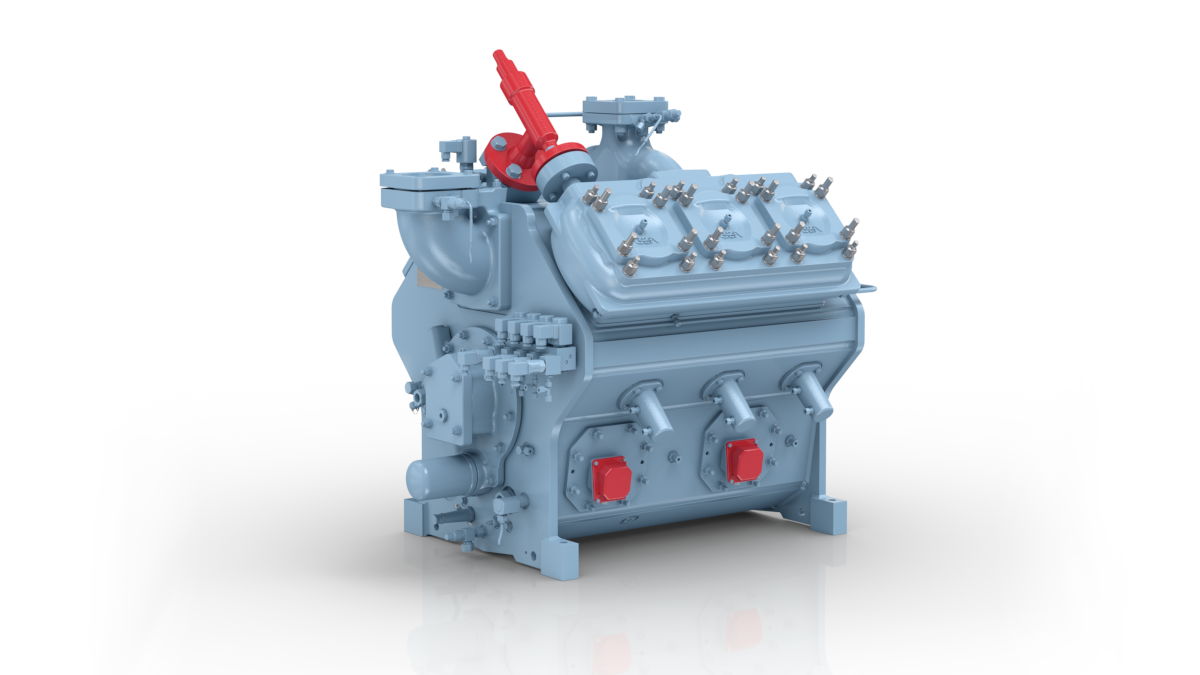

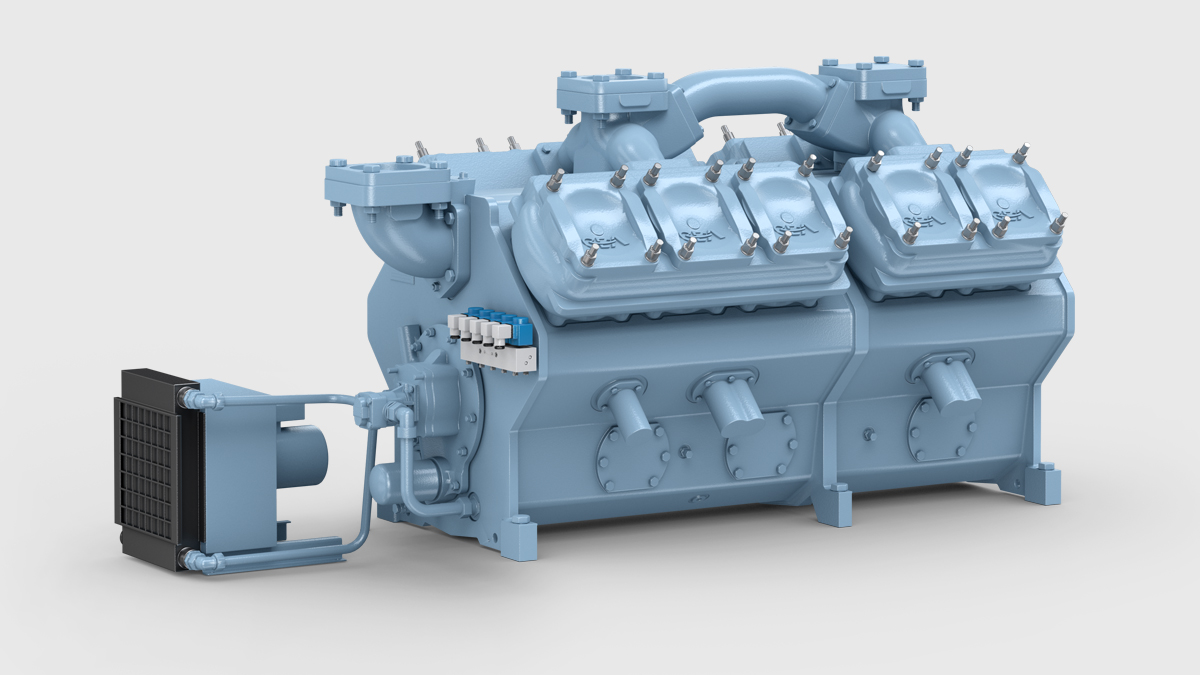

GEA Grasso V XHP

The GEA Grasso V XHP compressors, that use natural refrigerants such as ammonia, are designed to minimize their environmental impact. With the ability to reach water temperatures of up to 95°C / 203°F and offering best-in-class efficiency, they are an ideal choice for heat pump systems.

GEA Grasso V series reciprocating compressors offer the efficiency, quality and reliability needed to achieve the lowest possible total cost of ownership (TCO) throughout their service life. A unique, welded compressor housing minimizes thermal losses owing to outstanding suction and discharge separation. This, along with the optimized gas flow within the compressor, results in very high efficiency and extremely low oil carryover. No additional cylinder head cooling is required.

Sustainability

The V series is designed to use the natural refrigerant ammonia (R717) to achieve the highest efficiency. It can be used for both heating and cooling for a wide range of applications, and can achieve industry-leading hot water temperatures of up to 95°C / 203°F.

Reliability

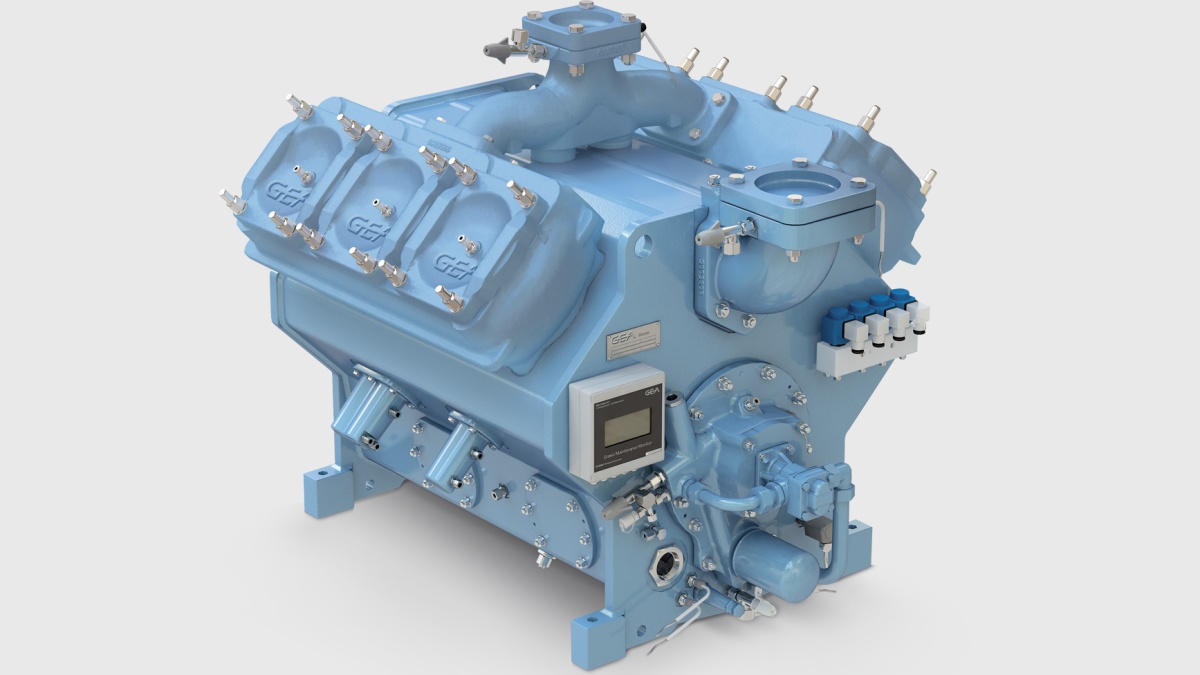

The use of high-end materials and proven technology helps to ensure maximum reliability. In addition to the standard benefits of the V series compressors, features such as a unique drain system and continuous safety monitoring are integrated in the design to maximize reliability.

Service

The electronically measured flexible and extended service intervals, minimize maintenance costs during the long service life of these compressors.

Efficency

A unique, welded compressor housing minimizes thermal losses owing to outstanding suction and discharge separation. This, along with the optimized gas flow within the compressor, results in very high efficiency and extremely low oil carryover. No additional cylinder head cooling is required.

Highlights & Technical Features

- Low total cost of ownership

- Efficiency and capacities according to EN 12900 and EN 13771, best efficiency available

- Unique, welded compressor housing for outstanding temperature separation

- Low oil carryover

- ISO VG 68 oil is approved to simplify the oil return design

- No cylinder head cooling required

- Low noise level

- Designed for ammonia as a natural refrigerant: zero ODP, zero GWP

- High-end materials and proven technology

- Electronically controlled service intervals – minimize maintenance costs

- Unique, integrated drain system to maximize reliability

| Models of GEA Grasso V XHP | V 350 XHP (4 cylinder) / V 550 XHP (6 cylinder) / V 750 XHP (8 cylinder) / V 950 XHP (10 cylinder) |

| Refrigerant | R717 |

| Heating capacity 35 / 95 °C (95 / 203°F) | Approx. 700 to 2300 kW (2388 to 7847 MBH) |

| Maximum discharge pressure | Tc = 95°C / 203°F |

| Speed minimum / maximum | 500 / 1500 rpm |

| Total swept volume at full load 1500 rpm | 376 to 941 m3/hr (221 to 554 CFM) |

| Drive type | Direct drive |

| Design discharge pressure | 63 bar(g) / 913.7 psi |

| Controls | GEA Omni control panel |

Looking for the efficiency reciprocating compressor?

GEA RedGenium

GEA Grasso V XHP, a proven high-efficiency reciprocating compressor, is also available for high-temperature heat pump applications, particularly for use with the GEA RedGenium heat pump.

The GEA Grasso V XHP series can achieve water temperatures of up to 95°C / 203°F with a maximum design pressure of 63 bar(g) / 913.7 psi and offers a wide capacity range up to 2.300 kW. This makes this model the first choice for hot-water applications to meet industrial requirements for food & beverage, district heating, and other applications.

GEA BluGenium

Related Videos

GEA Grasso V series reciprocating compressor

GEA RedGenium now up to 95°C/203°F

Related Products

GEA Purger

The GEA Purger removes non-condensable gases from your refrigeration system, maximizing system efficiency.

GEA Grasso V HS

GEA’s industrial reciprocating compressors stand for reduced total cost of ownership (TCO) thanks to less power consumption and maximum reliability.

GEA Grasso 5HP series

Reciprocating compressors for CO2 freezing and NH3 heat pump applications.

GEA Grasso V series

Reciprocating compressors for industrial refrigeration

Downloads

GEA Insights India

All pharmaceutical freeze-drying vials are the same! Aren't they?

Whether it’s a fad or the future, 100% vial traceability is becoming an increasingly important consideration in the pharmaceutical freeze drying industry. Keeping a close eye on developments is GEA. We’re investigating possible solutions and, what’s more, we have the experience, expertise and know-how to implement them.

Alcohol-free beer: They want it all – they want less

There was a time when the phrases ‘non-alcoholic beer’ and ‘tastes good’ were seldom used together in the same sentence, particularly by consumers. But low-proof and alcohol-free beers have come a long way – many of them now refreshing drinks in their own right – thanks in no small part to technology from GEA.

Innovating patient care with aseptic spray drying

At GEA, our commitment to engineering for a better world fuels our pursuit of innovative solutions that enhance patient care and safety. One of our most promising ventures in recent years is aseptic spray drying – a technology that promises to revolutionize pharmaceutical manufacturing.